Detailed instructions for use are in the User's Guide.

[. . . ] Optional anti-icing glass increases visibility and working capability.

Maximum Control, Maximum Comfort

Caterpillar has built the most comfortable cab in the industry, replacing the control levers and steering wheel with two joystick controls, and lengthening the cab for more leg room. Machine design features, like angled doors, provide excellent visibility.

Operator Comfort

The Cat® Comfort Series suspension seat and arm/wrist rests are fully adjustable for improved comfort and productivity. Extra leg room, easy-to-reach long-life rocker switches and revolutionary joystick controls make this the most comfortable cab in the industry.

Standard HVAC system

The high capacity system dehumidifies and pressurizes the cab, circulates fresh air, seals out dust and keeps windows clear.

Low Interior Sound and Vibration Levels

Multiple isolation mounts along with relocated hydraulic pump and valves significantly improve operator comfort and productivity.

In-Dash Instrument Cluster

Easy-to-read, high-visibility gauges and warning lamps keep the operator aware of critical system information.

3

Steering and Implement Controls

Unprecedented precision and ease of operation.

Ease of Operation

Two electro-hydraulic joysticks require up to 78% less hand and wrist movement than conventional lever controls for greatly enhanced operator comfort and efficiency. The intuitive control pattern allows both new and experienced operators to quickly become productive.

Joystick Functions

Optimum control at your fingertips: · The left joystick primarily controls the machine direction and speed including steering, articulation, return-to-center, wheel lean, gear selection, left moldboard lift cylinder and float. [. . . ] The front 240° of circle teeth are hardened to reduce wear and ensure component reliability.

Articulation Hitch

A large tapered roller bearing at the lower pivot carries loads evenly and smoothly. Sealed to prevent contamination, a locking pin prevents articulation for safety during service or transport.

Aggressive Blade Angle

Allows material to roll more freely along the blade, particularly dry materials or cohesive soils. Better material control gets the job done faster, requires less power and saves fuel.

Fast, Easy Adjustment Means Tight Components

Shims and patented top-adjust wear strips are easy to add or replace, dramatically reducing downtime and operating costs. Durable nylon composite wear inserts maximize circle torque and component life. Sacrificial brass wear strips between the blade mounting group and moldboard can be replaced easily. Shimless Moldboard Retention System uses vertical and horizontal adjusting screws to keep moldboard wear strips aligned for reduced blade chatter, precise blade control and dramatic reductions in service time.

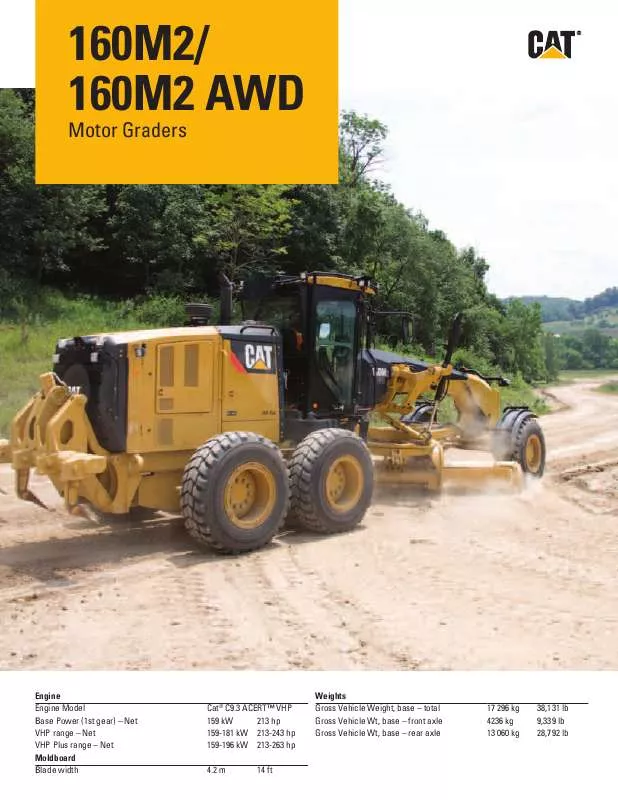

Moldboard

Heat-treated rails, hardened cutting edges and end bits, and heavy duty bolts assure reliability and long service life. The link bar allows extreme moldboard positioning for bank sloping, ditch cutting and cleaning.

7

All Wheel Drive (AWD)

Expanded machine versatility.

All Wheel Drive (AWD)

The AWD arrangement utilizes dedicated left and right pumps for precise hydraulic control. The infinitely variable pumps and motors maximize torque in each gear delivering the most power to the ground in the industry and increasing productivity.

Maximum Net Power

When AWD is engaged, flywheel horsepower is automatically increased by an additional 41 kW (55 hp) compared to the rear drive model. This offsets the parasitic losses and maximizes net power to the ground for increased productivity.

Hydrostatic Mode

Standard with AWD, this mode disengages the transmission and provides hydraulic power to the front wheels only. The ground speed is infinitely variable between 0-8 km/h (0-5 mph), perfect for precise finish work.

Steering Compensation

Cat Steering Compensation System enables a "powered turn" by adjusting the outside front tire speed up to 50% faster than the inside tire. The result is improved control, less damage to surfaces and a dramatic reduction of turning radius in poor underfoot conditions.

8

Hydraulics

Advanced machine control.

Advanced Electro-Hydraulic System

Incorporates a state-of-the-art electro-hydraulic system as the foundation for revolutionary changes in machine and advanced joystick controls.

Blade Float

Allows the blade to move freely under its own weight. By floating both cylinders, the blade can follow the contours of the road, especially useful when removing snow. Integral hydraulic and electrical components are standard on M2 Series (Grade Control Ready). · The optional Cat AccuGradeTM System automatically controls the blade, improving operator efficiency and productivity. AccuGrade technology reduces the need for traditional survey stakes or grade checkers, so you can reach grade faster and in fewer passes. The AccuGradeTM Attachment Ready Option provides additional mounting brackets, cab controls and electrical harnesses for easy installation of Cross Slope, Sonic, Laser, GPS or ATS electronics kits.

·

AccuGradeTM Attachment Ready Option

The AccuGrade System is fully integrated into the machine design, making installation quick and easy. Integral hydraulic and electrical components are standard on the M Series 2 (Grade Control Ready). The AccuGrade Attachment Ready Option provides additional mounting brackets, cab controls and electrical harnesses for easy installation of the Cross Slope, Sonic, Laser, GPS or ATS electronics kits.

Automatic Engine Deration

Protects the engine by automatically lowering engine torque output and alerting the operator if critical conditions are detected.

10

Work Tools and Attachments

Equip your machine for the job.

Moldboard Options

Standard moldboard is 4. 3 m × 610 mm (14 ft × 24 in). Caterpillar offers a 4. 3 m × 686 mm (14 ft × 27 in) and a 3. 7 m × 610 mm (12 ft × 24 in) as options. Left side extensions are also available.

Ground Engaging Tools (GET)

A variety of tools are available from Cat Work Tools, including cutting edges, graderbits and end bits, all designed for maximum service life and productivity.

Front Mounted Groups

A front mounted push plate/counterweight or front lift group are available. [. . . ] · For a complete list of tire options, contact your local Cat dealer.

17

160M2/160M2 AWD Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

POWER TRAIN Air cleaner, dual stage, dry type, diesel, with automatic engine derate and automatic dust ejector, service indicator through Cat Messenger Air-to-air after cooler (ATAAC) Belt, serpentine, automatic tensioner Brakes, oil disc, four-wheel, hydraulic Demand fan, hydraulic Differential, lock/unlock Drain, engine oil, ecology Electronic over speed protection Engine, C9. 3 with ACERT Technology, Tier 4 Interim and EU Stage IIIB emissions regulations Fuel tank, 416 L (110 gal), ground level access and sediment drain Muffler, under hood Parking brake multi-disc, sealed, oil-cooled Priming pump, fuel Rear axle, modular Sediment drain, fuel tank Tandem drive Transmission, 8F/6R, power shift, direct drive VHP (Variable Horsepower) ELECTRICAL Alarm, back up Alternator, 150 ampere, sealed Batteries, maintenance free, heavy duty, 1125 CCA Breaker panel, ground accessible Cab harness and electrical hydraulic valves Electrical system, 24V Grade Control Ready Cab harness, software, electrical hydraulic valves, bosses and brackets Lights, roof-mounted roading, reversing, LED stop and tail Product Link Ready Starter, electric OPERATOR ENVIRONMENT Accelerator Air conditioning with heater Arm and wrist rest, adjustable Articulation, automatic Return-to-Center Ashtray and lighter Cat® Messenger operator information system Centershift pin indicator Coat hook Cup holder Display, digital speed and gear Doors, left and right side with wiper Gauge, machine level Gauge cluster (analog) fuel, articulation, engine coolant temp, engine rpm, hydraulic oil temp, regen Hour meter, digital Joystick hydraulic controls right/left blade lift with float position, circle drive, blade sideshift and tip, centershift, front wheel lean, articulation and power steering Joystick, adjustable armrests Joystick gear selection Joystick hydraulic power steering Ladders, cab, left and right side Lights, night time cab Mirror, inside rearview, wide angle Power port, 12V Radio Ready, Entertainment ROPS cab, sound suppressed 70 dB(A) Seat, cloth-covered, comfort suspension Seat belt, retractable 76 mm (3 in) Storage area for cooler/lunchbox Throttle control, electronic Windows, laminated glass: fixed front with intermittent wiper side and rear (3) FLUIDS Antifreeze Extended Life Coolant to 35° C (30° F) TIRES, RIMS AND WHEELS Partial allowance for tires on 254 × 607 mm (10 × 24 in) multi-piece rims is included in the base machine price and weight OTHER STANDARD EQUIPMENT Accumulators, brake, dual certified Anti-glare paint Bumper, rear, integrated with hitch CD ROM Parts Book Clutch, circle drive slip Cutting edges 152 × 16 mm (6 × 5/8 in) curved DH-2 steel 19 mm (3/4 in) mounting bolts Doors (3), engine compartment, locking Drawbar 6 shoes, replaceable wear strips Electrical hydraulic valves, hydraulic lines for base 8 functions Endbits 16 mm (5/8 in) DH-2 steel 19 mm (3/4 in) mounting bolts Fluid check, ground level Frame, articulated, with safety lock Ground level engine shutdown Hammer (emergency exit) Horn, electric Hydraulic lines for base functions Lockout, hydraulic implement (for roading and servicing) Moldboard 4267 × 610 × 22 mm (14 ft × 24 in × 7/8 in) Mounting, cab roof accessories Pump, hydraulic, high capacity, 98 cm³ (6 in³) Radiator, cleanout access (both sides with swing doors) Secondary steering Serviceability, LH side S·O·SSM ports: engine, hydraulic, transmission, coolant, fuel Tandem walkway/guards Tool box Tow hitch

18

160M2/160M2 AWD Optional Equipment

Optional equipment may vary. Consult your Cat dealer for details.

kg ELECTRICAL Alternator, 250 ampere 2 Batteries: extreme duty, 1, 400 CCA Converter, communication (CB) Lights: Headlights, high Headlights, low Working lights, basic Working lights, plus Warning: Beacon or Strobe Mounting for Warning Light GUARDS Fenders, Front Fenders, Rear Sound suppression (Bottom) Sound suppression (Enclosure) Transmission 14 5 5 30 11 lb POWER TRAIN All Wheel Drive Differential Lock, Automatic Engine, variable horsepower plus (VHP Plus) Fuel tank, fast fill Oil, Hydraulic, Biodegradable Synthetic Precleaner, snow Starter, Heavy Duty, 1, 000 Amp Transmission, autoshift 590 9 00 1, 300 20 00 kg lb WORK TOOLS/G. E. T. Blade extension, left hand, 610 mm (2 ft) Cutting Edges, curved Endbits, overlay Front lift group, mounting Front lift group, mechanical Grader bit, narrow and super penetration Mid-Mount Scarifier, Package Mid-Mount Scarifier, Mounting Moldboard 4267 × 686 × 25 mm (14 ft × 27 in × 1 in) 3658 × 610 × 22 mm (12 ft × 24 in × 7/8 in) Push plate, counterweight Ripper, mounting Ripper, rear Ripper tooth Scarifier, front Snow Arrangement Snow Wing Ready Package 113 43 24 5 680 181 942 57 249 95 52 11 1, 500 400 2, 077 125 kg lb

5 5 9 10 2 5

11 11 20 22 5 11

14 00

31 00

2 10 2

4. 4 22 5

56 34 110 110 141

123 75 243 243 311

OPERATOR ENVIRONMENT Anti-icing Glass 14 Fan, defroster, 2 rear window Mirrors, outside: heated 24V mounted Precleaner, HVAC Radio ready, AM/FM Seat, air suspension, cloth Shade, sun Wiper/washer, rear 15 15 5 9 2 2 2

31 4

33 33 10 20 5 5 4

OTHER ATTACHMENTS AccuGrade ARO 39 Accumulators, 77 blade lift AutoLube, Lincoln 23 AutoLube, Lincoln, 5 ripper enhancement Camera, rearview 9 Cat Product Link 5 321SR Compressor/tank, Air 23 Drain, ecology, engine 2 Wiggins Fenders, front, AWD 56 Fenders, rear 119 Heater, engine coolant:

85 170 50 10 20 10 50 5 124 262

257

567

885 32 962 28 434 161 114

1, 951 70 2, 120 61 956 355 355

120V 1 3 220V 1 3 Hydraulic arrangements with one or more additional hydraulic valves are available for rear ripper, dozer, snow plow and snow wing. [. . . ]