Detailed instructions for use are in the User's Guide.

[. . . ] These brakes provide outstanding stopping capability, while maintaining maximum durability and low wear characteristics.

Rear Suspension

Features a walking beam geometry with Caterpillar designed rear suspension mounts which provide a reliable and stable ride for excellent load retention.

Traction Control

The traction control system is comprised of a wet clutched inter-axle differential and wet clutched cross-axle differentials. All differentials can be engaged and disengaged on-the-go for maximum versatility. When used together, the differentials provide 100 percent driveline locking.

Inter-Axle Differential Lock

Locks all three axles in unison and modifies torque distribution for excellent traction in poor underfoot conditions and on grades. [. . . ] The divergent frame design decreases stress in the hitch area and optimizes suspension geometry. The frame design makes maximum use of robotic welding for increased durability.

Rear Frame

Twin-box construction minimizes stress concentrations and provides low weight with long service life.

Suspension

The three-point oscillating axle front suspension provides unparalleled ride quality. It also protects the truck from adverse road conditions by absorbing shock loads that would reach the frame.

Articulating/Oscillating Hitch

The articulating hitch provides the truck with steering articulation, and the oscillation ensures all-wheel ground contact in rough terrain.

Hitch Construction

Two-piece construction features a durable cast steel head bolted to a hard-wearing forged steel tube.

Fast Hoist Cycle Times

Fast body raise and lower times mean less time spent in the dump area.

Load-Carrying Capacity

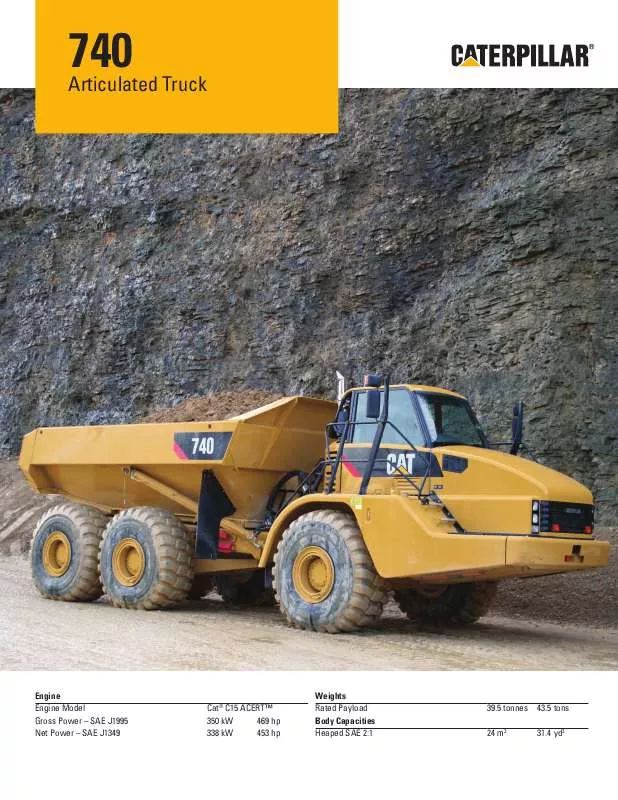

The 740 has a large target area to provide consistently high load-carrying capacity. Its diverging flow design gives clean load ejection, which maximizes production and avoids the waste of material carry-back.

7

Serviceability

More time on production.

Long Service Intervals

Long engine oil change and hydraulic oil change intervals lower maintenance costs and downtime. Wheel-bearing adjustment is completely eliminated.

Lube Points

Lube points are grouped at the rear of the front frame and the front of the rear frame. Universal joints are lubed for life, eliminating servicing. Autolube is optional.

Service Points

Engine and transmission dipstick and fill caps, air and fuel filters, and the fuel priming pump are all mounted on the left side of the engine under the electrically raised hood. Coolant level indicator and fill cap are outside the cab.

Radiator

The radiator package is located behind the cab, which provides protection from frontal impacts and offers easy access to the inlet and outlet sides of the radiator. The ATAAC radiator is located at the front of the truck.

Extended Life Coolant

Extends the change interval and improves component life by reducing aluminum corrosion.

Electrical Service Center

Located inside the cab, this service center provides a power port, diagnostic connector and Cat Data Link connector.

Cat Data Link Connector

The Cat Data Link connector provides a plug-in using a laptop computer with Electronic Technician (ET) software.

Service Access

The cab tilts to the side to provide easy access underneath, which simplifies access of the transmission, drive shafts and hydraulic pumps. Machine electrical and hydraulic interfaces are located on the right side of the cab, behind a removable cab body panel for easy access.

Truck Transport

The suspension system eliminates the need to lower the suspension when transporting the truck, reducing maintenance and downtime.

Output Transfer Gear

Provides lubrication of all bearings and clutches using a distributed-pressure lubricated and filtered system.

8

Product Link

Equipment Manager is a secure and user-friendly application.

Equipment Manager a better way to manage your fleet

Equipment Manager allows transmitted data to be searched and sorted by alert level, group, equipment identification, make and model. Each new machine comes with Asset Watch. However, you can subscribe to a higher level of service for any machine, at any time, through your Cat dealer. Can be manually selected for machine recovery purposes External engine fuel cut off switch for easy access from outside of the machine External electrical system disconnect switch for easy access from outside of the machine Slip resistant surfaces punched steel plate 75 mm (3 in) wide seat belts for operator and passenger/ trainee Wide angled mirrors for excellent rear visibility Sweeping hood design for panoramic forward visibility Extensive hand rails Body raised alarm Heated mirrors (optional) Xenon flashing beacon (optional)

· · · · · · · · · ·

11

740 Articulated Truck Specifications

Engine

Engine Model Gross Power SAE J1995 Net Power SAE J1349 Net Power ISO 9249 Net Power EEC 80/1269 Bore Stroke Displacement Cat® C15 ACERTTM 350 kW 469 hp 338 kW 342 kW 342 kW 137 mm 171. 5 mm 15. 2 L 453 hp 458 hp 458 hp 5. 4 in 6. 75 in 926 in3

Transmission

Forward 1 Forward 2 Forward 3 Forward 4 Forward 5 Forward 6 Forward 7 Reverse 1 Reverse 2 8. 9 km/h 12. 1 km/h 16. 4 km/h 22 km/h 30 km/h 40 km/h 54. 7 km/h 8. 4 km/h 11. 6 km/h 5. 5 mph 7. 5 mph 10. 2 mph 13. 7 mph 18. 6 mph 25. 1 mph 34 mph 5. 2 mph 7. 2 mph

Body Plate Thickness

Front Scow Side Base 8 mm 16 mm 12 mm 16 mm 0. 31 in 0. 63 in 0. 47 in 0. 63 in

Service Refill Capacities

Fuel Tank Cooling System Hydraulic System Engine Crankcase Transmission Final Drives/ Differential Output Transfer Gear Box 532 L 80 L 328 L 38 L 72 L 72 L 18 L 140. 5 gal 21. 1 gal 86. 6 gal 9. 5 gal 19 gal 19 gal 4. 8 gal

Sound Levels

Interior Cab 79 dB(A) · The operator sound exposure Leq (equivalent sound pressure level) measured according to the work cycle procedures specified in ANSI/SAE J1166 OCT 98 is 79 dB(A), for the cab offered by Caterpillar, when properly installed and maintained and tested with the doors and windows closed. · Hearing protection may be needed when operating with an open operator station and cab (when not properly maintained or doors/windows open) for extended periods or in noisy environments.

· The power ratings apply at rated speed of 1, 800 rpm when tested under the conditions for the specified standard. [. . . ] Retarding effect on these curves represents full application of the retarder.

GROSS WEIGHT

0 0 20 10 40 20 60 30 80 40 100 50 120 60 140 70 160 180 lb x 1000 80

kg x 1000

1

35%

30%

25%

E

L

20%

2

15%

3

10%

4 5 6 7

5%

0 0 5

10 10

20 15

30 20

40 25 30

50 35

60 40

70

km/h

45 mph

SPEED

1 1st Gear 2 2nd Gear 3 3rd Gear 4 4th Gear 5 5th Gear 6 6th Gear 7 7th Gear

E Empty 33 100 kg (72, 973 lb) L Loaded 72 600 kg (160, 055 lb)

16

% EFFECTIVE GRADE (FAVORABLE)

740 Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details

Air conditioning with R134A refrigerant Air vents, adjustable Auto shift seven-speed forward and two-speed reverse transmission Back up alarm Body, adapted for exhaust heat Cat® C15 engine with ACERTTM Technology Caterpillar Work Area Vision System (WAVS) rear-view camera CD/Radio, heavy duty Differentials, standard with clutched crossaxle differential locks for all axles Electrical system: 24 volt, 5A 24- to 12-volt converter Electro hydraulic hoist control Ether starting aid Glass windows, laminated and tinted, front Glass windows, toughened and tinted, sides and rear Guards: rear window, radiator, crankcase and axle Headlights, four Heater and defroster with four-speed fan Horn, electric Lights: cab interior, front, side, rear, two reversing/working lights, two stop/tail lights, front and rear direction indicators Mirrors, main and auxiliary, left and right Mud flaps, wheel arch and body mounted, with transportation tie backs Oil-cooled brakes, enclosed Product Link (US/Canada/Europe/Turkey/ Australia/New Zealand) Retarder, Engine compression brake ROPS/FOPS cab, with full instrumentation, including: Instrument cluster display module Indicator lamps: left turn, secondary steering, primary steering loss, front and rear brake temp (735/740 and 740 Ejector only), brake oil pressure, action lamp, transmission fault, park brake, charging system status, differential lock, body not in float, right turn, high beam, transmission hold, machine filter warning, retarder, retarder up shift warning Gauges: engine oil pressure, engine coolant temperature, torque converter oil temperature, fuel level, fuel tank level gauge Meters: service hour meter, speedometer, tachometer Seat, fully adjustable, air suspension Seat, padded companion/trainer Secondary steering electronic S·O·SSM sampling valves Spill guard, front, integral part of fabricated body Starting receptacle, electric, remote Storage two cup holders, flask receptacle, under seat storage, door pocket, behind seat storage, coat hook. Sun visor Three-axle, six wheel drive Tilt and telescopic steering wheel Tires, 29. 5R25, radial Tow pins, front and rear Two Seat belts, Drivers retractable Vandalism protection: lockable caps for fuel tank and hydraulic oil tank Windows opening side, tinted Windshield wiper and washer, two speed, intermittent (front) Windshield wiper and washer, two speed, (rear)

740 Optional Equipment

Optional equipment may vary. [. . . ]