Detailed instructions for use are in the User's Guide.

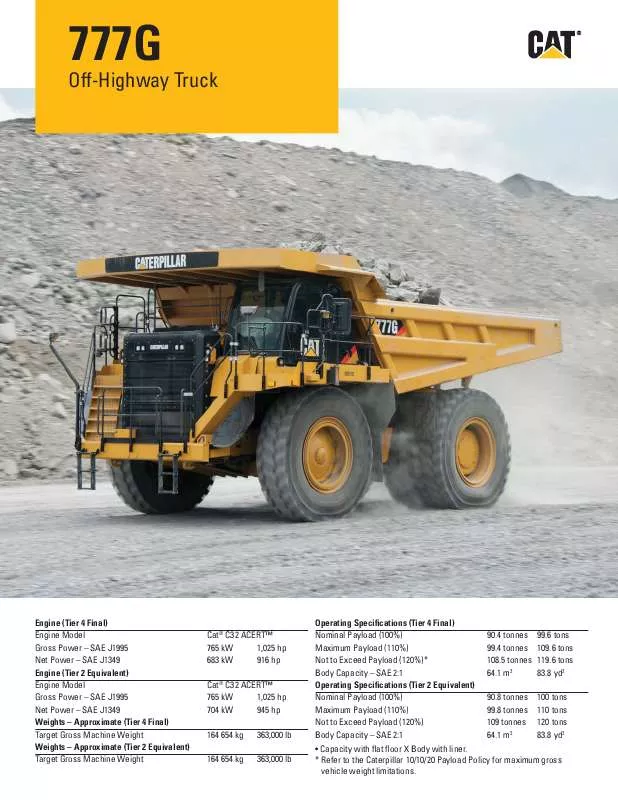

[. . . ] 777G

Off-Highway Truck

Engine (Tier 4 Final) Engine Model Gross Power SAE J1995 Net Power SAE J1349 Engine (Tier 2 Equivalent) Engine Model Gross Power SAE J1995 Net Power SAE J1349 Weights Approximate (Tier 4 Final) Target Gross Machine Weight Weights Approximate (Tier 2 Equivalent) Target Gross Machine Weight

Cat ® C32 ACERTTM 765 kW 1, 025 hp 683 kW 916 hp Cat ® C32 ACERTTM 765 kW 1, 025 hp 704 kW 945 hp 164 654 kg 164 654 kg 363, 000 lb 363, 000 lb

Operating Specifications (Tier 4 Final) Nominal Payload (100%) Maximum Payload (110%) Not to Exceed Payload (120%)* Body Capacity SAE 2:1 Operating Specifications (Tier 2 Equivalent) Nominal Payload (100%) Maximum Payload (110%) Not to Exceed Payload (120%) Body Capacity SAE 2:1

90. 4 tonnes 99. 4 tonnes 108. 5 tonnes 64. 1 m3 90. 8 tonnes 99. 8 tonnes 109 tonnes 64. 1 m3

99. 6 tons 109. 6 tons 119. 6 tons 83. 8 yd3 100 tons 110 tons 120 tons 83. 8 yd3

· Capacity with flat floor X Body with liner. * Refer to the Caterpillar 10/10/20 Payload Policy for maximum gross vehicle weight limitations.

Features G Series Customer Requirements meet safety and regulatory requirements machine available when scheduled to work performance that promotes low owning and operating costs provide an operating environment that enhances productivity G Series Quality G Series is backed by comprehensive virtual validation, prototype testing and over 25, 000 hours of work in the hands of customers prior to production. G Series Performance The 777G has 7% more torque and new transmission controls that deliver quick haul cycles with automotive-quality shifting and comfort. G Series Economics G Series introduces new fuel saving strategies and component life goals to help manage life cycle costs. [. . . ] · TPMS stores 2, 400 payload cycles; reports on weights, haul cycle times, distances, with date and time stamps.

Ton Kilometer per Hour (TKPH), Ton Mile per Hour (TMPH) Tire Monitoring

This program takes the payload value from TPMS, combines it with ambient air temperature, machine speed and the manufacturer's TKPH (TMPH) rating for your tires and calculates tire condition continuously. As a tire approaches its calculated limits, the operator gets a warning inside the cab. This Caterpillar exclusive feature is an important tool in your efforts to extend tire life.

Cat Product Link

Cat Product Link allows remote monitoring of equipment to improve overall fleet-management effectiveness. Product Link is deeply integrated into machine systems. Events and diagnostic codes, as well as hours, fuel, idle time and other detailed information are transmitted to a secure web based application, VisionLinkTM. VisionLink includes powerful tools to convey information to users and dealers, including mapping, working and idle time, fuel level and more. * Product Link licensing not available in all areas. Please consult your Cat dealer for availability.

11

Cat MineStar System

Efficiently manage your fleet, machine health and enhance safety

Cat MineStarTM System is the industry's broadest suite of integrated mine operations and mobile equipment management technologies, configurable to suit your operation's needs. Its capability sets Fleet, Terrain, Detect, Health and Command contain a range of technologies that let you manage everything from fleet assignment and condition monitoring to remote and autonomous control. The 777G can be equipped with many of these advanced technologies.

Fleet

Fleet makes it easy to keep your operation running safely and at peak performance, with real-time control. This optional system consists of on-machine and office technologies, enabling your operations to easily drill down for detailed views and analysis, determine the impact of operational changes prior to implementing them, and analyze reporting on selectable groups of assets down to individual machines. Fleet can work with data from all types of assets and equipment including off-highway trucks, wheel loaders, motor graders, wheel dozers, shovels, light duty vehicles and equipment from other manufacturers helping you reduce costs per ton, enhance productivity and boost overall site profitability.

Detect

Object Detection, one of the capabilities of Detect, comes standard on the 777G. Using a combination of radars, an in-cab display, and multiple cameras, Object Detection provides equipment operators with enhanced awareness for increased site safety. At startup, slow speed operation or whenever a machine stops for a set period of time, the touch screen display alerts the operator when objects have entered critical areas around the equipment. Radars communicate with the in-cab display to provide a visual indication of where objects are relative to the machine along with proximity bars to inform the operator of distance to the detected object. The system can be configured for distance or speed-based standby mode. Both visual and audible warnings are provided when an object has been detected while the machine is in gear and attempts to move towards the object. An optional radar wash feature keeps debris off the cameras and radars, enabling your system to run effectively all shift long.

12

Health

By identifying many types of potential equipment problems before failure, Health works to minimize unscheduled downtime and productivity loss. Plus, it helps keep your 777G operating costs in check by streamlining service and maintenance management and scheduling. This optional system includes comprehensive maintenance and service planning capabilities. It enables managers to track what equipment is due for service, schedule repairs and maintenance, see what procedures have been performed and monitor how the machine is performing once it goes back to work. Health can also help identify issues beyond the equipment, including problem areas within the mine site itself. [. . . ] Effective grade equals actual % grade minus 1% for each 10 kg/t (20 lb/ton) of rolling resistance. From this weight-effective grade point, read horizontally to the curve with the highest obtainable gear, then down to maximum descent speed brakes can properly handle without exceeding cooling capacity. The following charts are based on these conditions: 32° C (90° F) ambient temperature, at sea level, with 27. 00R49 (E4) tires. NOTE: Select the proper gear to maintain engine rpm at the highest possible level, without overspeeding the engine. [. . . ]