Detailed instructions for use are in the User's Guide.

[. . . ] A sight level gauge replaces the dip stick.

3

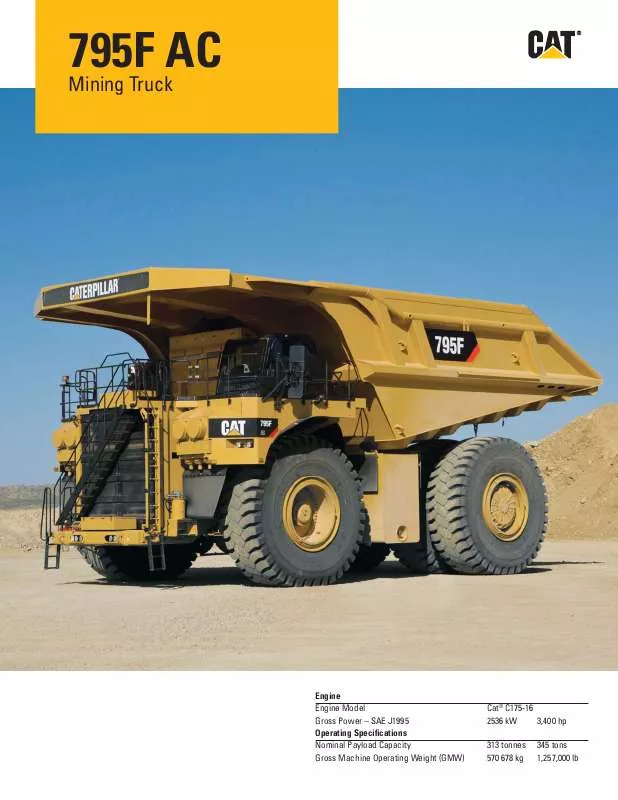

Power Train Cat AC Electric Drive

More power to the ground for greater productivity.

Why Electric Drive?

Cat mechanical drive trucks are the standard of the industry and are favored in most applications. Some customers, however, prefer electric drive for specific applications and situations.

100% Caterpillar

Designed and manufactured by Caterpillar, the 795 is the first AC electric drive truck that is single sourced from one manufacturer and supported by the best dealer network in the industry. The 795 power train works seamlessly with the C-175 engine and offers unsurpassed Safety, Serviceability and Performance.

Modular Design for Excellent Serviceability

The modular design allows ease of component removal and installation. The engine, generator, motors, inverter, grid, and final drives can be removed independently. [. . . ] The 795 offers exceptional non-fade braking and supplemental retarding at all speeds.

Traction Control with Automatic Front Brake Blending

If the truck senses any slip the front brakes will automatically engage. The addition of front braking keeps the truck moving in the intended direction and the operator in control. This blended braking capability is an industry first and has been enthusiastically received by operators. In addition, the operator can select full time front brake blending.

Automatic Retarding Control

Operator controlled ARC engages automatically and maintains speed consistently. A simple toggle switch is used to adjust retarding speed.

Parking Brake

The oil cooled, spring applied, hydraulically released parking brake on all wheels provide superior parking capability on grades up to 15%.

Control to Prevent Exceeding Retarding Capability

Built into the software is a Grid Thermal Calculator that constantly monitors power to the grid. When dynamic retarding capability is exceeded the mechanical brakes are blended in automatically. This will continue as long as necessary.

Often this is a transient condition. The operator is alerted to take corrective action if this continues. The brake blending is smooth and seamless.

Anti-Rollback

Automatically applies service brakes to prevent the truck

from rolling from a stop opposite the intended direction

of travel.

Reverse Shift Inhibit

Ensures reverse propulsion is not applied when the machine is moving forward.

Brake Design

Cat oil cooled brakes are designed with large discs and plates for reliable and adjustment free operation. They are enclosed and sealed to prevent contamination and provide long life.

7

Structures

Building on the legacy of superior, long life structures.

Box Section Design

The 795F AC uses a box-section design, incorporating forgings and castings in high stress areas with deep penetration, continuous wrap-around welds to resist fatigue from racking loads.

·

Steel Structures Mild steel used throughout the frame

provides flexibility, durability and resistance to impact and allows for field repairs with common weld practices.

·

Castings Large radii castings dissipate stress in areas

of high stress concentration. Castings allow welds to be placed in lower stress areas for longer frame life.

Integral Four-Post ROPS Cab

Resiliently mounted to the main frame to reduce vibration and sound, the integral ROPS cab is designed as an extension of the truck frame.

Suspension System

Designed to dissipate haul road and loading impacts for longer frame life and a more comfortable ride.

· ·

Durable Design Large diameter cylinders with nitrogen

over oil design for long life and minimal maintenance.

Front Cylinders Have preset caster and camber and

are mounted to the frame. They also serve as steering king pins for a tight turning radius.

·

Rear Cylinders Allows axle oscillation and absorb

bending and twisting loads from the haul road isolating them from the main frame.

Four-Bar Link Rear Suspension

Directs a more even load distribution into the main frame operators report a more secure feeling of the truck being well connected and under control.

Steering System

Single tie rod steering system is simpler and requires less maintenance.

8

Truck Body Systems

Cat Bodies for Cat Trucks

Caterpillar designed and built for rugged performance and reliability.

Integral to the truck the body is designed to fit with the chassis and work as part of the truck system. This shows a strong commitment to operator and operational safety.

Ergonomic Cab Layout

Controls are intuitive and within easy reach making the operator more comfortable, productive and safe. Operator feedback for the 795 is easy to learn and easy to control.

Viewing Area

The large viewing area offers exceptional visibility, allowing the operator to drive with confidence for high productivity. The right hand platform is free of obstructions for a clear view.

1) Air suspension seat with three-point operator restraint 2) Hoist lever 3) Secondary brake pedal 4) Advisor display 5) Adjustable steering column 6) Vehicle directional control 7) Gauges 8) Storage compartment 9) Full size trainer seat 10) Electric powered operator window 11) Turn signal and wiper controls 12) Ventilation controls 13) Four post ROPS 14) Cat Detect monitor 15) MineStar Monitor (optional) 16) Cup holder 17) Dome lights

11

Customer Support

Best dealer network with best service and parts support.

Commitment to Meet Your Needs

Cat dealer 24/7 support offers solutions, services and products to help lower costs, enhance productivity and manage your fleet anywhere in the world. Expert technicians have the knowledge, experience, training, parts and tooling to keep your 795 running at high availability.

Product Support

Caterpillar supports the 795 with a worldwide network of parts distribution, dealer service centers and technical training facilities. Our global dealer network is ready to meet your support needs around the clock and around the world.

Service Support

Cat dealers offer a wide range of service plans to maximize uptime and return on your investment, including: · Preventive Maintenance Programs · Diagnostic Services such as Scheduled Oil Sampling and Technical Analysis · Rebuild and Remanufactured Product Options · Customer Support Agreements

Application Awareness

Application and site-specific factors such as material density, loading practices, payload, speed, grade and haul road design and maintenance influence the cost to operate and maintain your haulage fleet. Your Cat dealer can provide help in understanding the effects application factors and operating practices have on maintenance and operating costs. They also offer training to help operators improve productivity, decrease downtime, reduce operating costs and enhance safety.

12

Serviceability

Modular Design

Reduced maintenance time results in more productivity.

Major components can be serviced individually with minimal removal and installation time. Work platforms and step/stairs are located in key service areas. Rear mounted generator is separate from the engine and can be removed without removing the body wheel motors are separate from final drives. [. . . ] The following charts are based on these conditions: 32° C (90° F) ambient temperature, at sea level, with 56/80R63 tires.

Typical Field Empty Weight

Gross Machine Operating Weight

570 166 kg (1, 257, 000 lb)

GROSS WEIGHT

0 0 200 100 400 200 600 300 800 400 1000 500 30% 1200 600 1400 lb x 1000 700 kg x 1000

25%

E

L

20%

15%

10%

5%

0 0 5

10 10

20 15

30 20

40 25

50 30 35

60 40

70 km/h

mph

SPEED

E Empty

L Loaded

*At sea level, 30° C (86° F).

Contact factory for performance estimates based upon site specific temperatures and altitudes.

20

TOTAL RESISTANCE (Grade Plus Rolling)

795F AC Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

ELECTRICAL Alarm, Back-up Brushless Alternator, 150 ampere Batteries, 210-amp hour, low maintenance, 12-volt (2) Converter, 12-volt electrical Electrical System, 24-volt, 10, 15 and 20 amp Battery Charge Receptacle Lighting System Back-up and Hazard Lights Directional Signals (front and rear LED) Front Stair Access/Service Deck Stop/Tail Lights (LED) Engine Compartment VIMS, Blue Light (LED) Headlights, with Lo-Hi Beam Selector OPERATOR ENVIRONMENT Air Conditioner with Automatic Climate Control 12-volt DC Power Supply (3) Coat Hook Cup Holder Diagnostic Connection Port Dome Courtesy Light Map Lights (2) Entertainment Radio Ready 20 amp Switched/10 amp Memory Converter, Speakers and Wiring Harnesses Gauge/Indicators Gauge Panel: Drive Train (system temperature) Brake Oil Temperature Engine Coolant Temperature Fuel Level Torque Converter Oil Temperature Electric Engine Control Fault Indicator Electric Hour Meter Speedometer Tachometer Heater/Defroster, 10 310 kCal (40, 912 BTU) Hoist, Body Control (electric) Horn (2) Cat Detect (Radar and Camera) System Mirrors, Right and Left ROPS Cab, Insulated/Sound Suppressed Seat, Operator, Air Suspension

Seatbelt, Operator, Three Points,

Retractable

Seatbelt, Trainer, Two Points, Retractable

Stairway and Walkway Access,

600 mm (23. 6 in)

Steering Wheel, Tilt, Padded, Telescopic

Storage Compartments

Tinted Glass

Transmission Gear Indicator

VIMS Message Center with Advisor

Window, Operator, Electric Powered

Windshield, Wiper Intermittent Control

and Washer

POWER TRAIN

Cat® C175-16 Tier 2 Emissions

Compliant Engine Air Cleaner with Precleaner (4) Air-to-Air Aftercooler (ATAAC) Automatic Starter Protection Ether Starting Aid (automatic) Multi-Point Oil Pressure Sensing Turbocharging (4)/Aftercooled Braking System Automatic Retarder Control, Adjustable Brake Release Motor (towing) Engine Overspeed Protection Extended Life Brake Disc Material Oil-cooled, Multi-disc (front and rear) Service, Retarding, Parking, Secondary Park Brake Integrated with Gear Selector Secondary, Emergency Cat AC Drivetrain IGBT controlled AC induction motors AC generator AC cooled radial grid Body-up Reverse Neutralizer Body-up Shift Inhibitor Directional Shift Management Neutral Coast Inhibitor Neutral Start Switch Programmable Top Speed Reverse Shift Inhibitor Pre-lubrication/Engine Rear Axle Continuous Lubrication/Filtration OTHER STANDARD EQUIPMENT Air Starter, Turbine Air System Dryer Automatic Lubrication System Aux "Buddy" Dumping Quick Connect Aux Steering Quick Connect (towing) Blended Retarding System Driveline Guards Exhaust Fuel Tank, 3596 L (950 gal) Fast Fill Fuel System Fuel Filter with Water Separator Ground Level Battery Lockout Ground Level Engine Shut-down Ground Level Engine Start Lockout Ground Level Machine Lockout Ground Level Transmission Lockout Ground Level VIMS Data Port Hi-speed Crankcase Oil Change Hydraulic Filters, 1, 000 hour Payload Indicator Lights Reservoirs (2 separate) Brake/Hoist, Steering/Fan Rock Ejectors Service Points, Ground Level Sight Level Gauges for Hydraulic/ Engine Oil S·O·SSM Sample Ports Supplemental Steering (automatic) Tie Down Eyes Tow Hooks and Pin (front) Tow Pin (rear) (Empty truck only) Traction Control System Vandalism Protection Locks Vital Information Management System (VIMS) Includes VIMS Payload Monitor with MAX Payload and Speed Manager VIMS 3G requires download cable 305-5528 VIMS 3G Connect PC software (reference media number EERP2001) and VIMS PC software JERD2175. Supplemental software "VIMS Supervisor" YERA1403. ANTIFREEZE

Extended Life Coolant to 35° C (30° F)

21

795F AC Optional Equipment

Optional equipment may vary. [. . . ]