Detailed instructions for use are in the User's Guide.

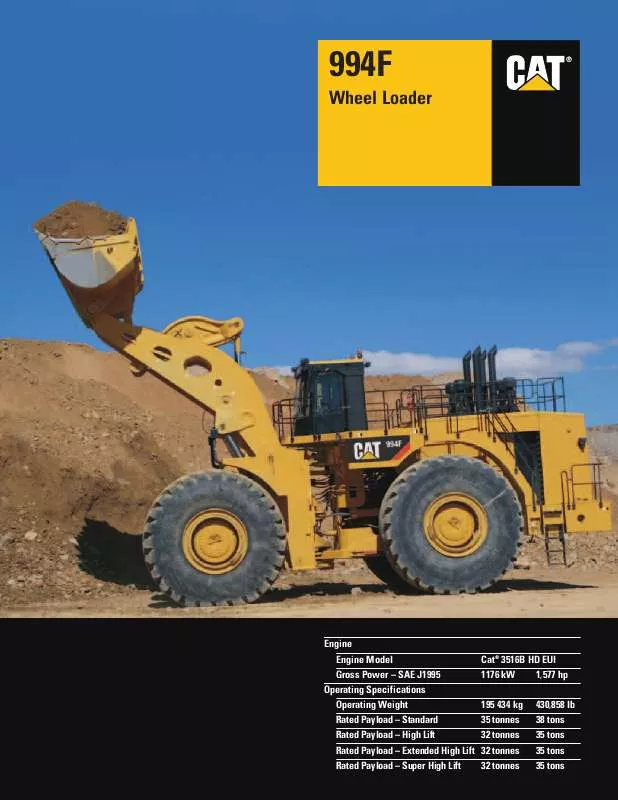

[. . . ] 994F

Wheel Loader

®

Engine Engine Model Gross Power SAE J1995 Operating Specifications Operating Weight Rated Payload Standard Rated Payload High Lift Rated Payload Extended High Lift Rated Payload Super High Lift

Cat® 3516B HD EUI 1176 kW 1, 577 hp 195 434 kg 35 tonnes 32 tonnes 32 tonnes 32 tonnes 430, 858 lb 38 tons 35 tons 35 tons 35 tons

994F Wheel Loader

Powerful, responsive and rugged, the 994F sets the standard for high productivity and durability.

Power Train The Cat® 3516B HD EUI engine delivers high horsepower to maximize productivity. Field proven for reliable performance in the most demanding applications, the 3516B HD EUI offers superior fuel efficiency, lower emissions, reduced engine noise and lower operating costs. 4 Structures Structural components are the backbone of the 994F's durability. The heavyduty box-section loader frame creates a durable, rugged machine. [. . . ] Provide low-effort control for enhanced comfort and stability. Controls and arm rests are fore, aft and height adjustable to accommodate operators of any size in a comfortable operating position. The levers are ergonomically designed for improved operator comfort. VIMSTM system is the standard display system that provides information on the machine's major components and systems. Gauge displays fuel tank level and temperatures for engine coolant, power train and hydraulic oil. Tachometer is an analog gauge with digital readout for gear selection. The Payload Control System is included in VIMS system.

· interior sound levels below 75 dB(A) · standard coat hook

· intermittent wet-arm wipers (front and rear) · radio ready

· CAES ready · rear vision camera ready · Product Link ready · VIMS wireless ready

11

VIMSTM Vital Information Management System

Vital machine information at your fingertips.

VIMS PC

9

ET

1

2 8 10

VIMS

7

11

1 2 3 4 5 6 7 8 9 10 11 12

Gauge Cluster Message Center and Keypad ADEM III Engine Control Module CAT Data Link Action Alarm Action Lamp Radio System (optional) Data Port (VIMS-PC) Service Lamp Diagnostic Connector (ET) Transmission ECM Implement

6 5 4

12

3

For the operator. VIMS system establishes a two-way communication between the operator and the machine. Real-time machine information allows the operator to make informed decisions that directly affect their safety, machine availability, and ultimately the productivity of the mine. VIMS system provides maintenance personnel an overview of operator and machine performance. This allows maintenance managers and technicians the information necessary to maximize component life, reduce catastrophic failures, minimize unscheduled downtime and improve a mine's asset management.

Production. VIMS system collects the information a manager needs to determine equipment usage, future machine requirements, personnel performance, and productivity levels. Payload information can also be used as an accounting tool, an indicator of cycle time efficiency and truck over loading or under loading. Sensors located throughout the machine systems enable the VIMS system to quickly exchange and monitor information from all machine systems for efficient, high performance operation. VIMS system simplifies troubleshooting, reduces downtime and lowers operating costs by identifying abnormal conditions before they cause extensive damage.

Data Access. Monitoring and diagnostic information is stored on board until it can be downloaded for analysis. Data can be accessed through the message center, transmitted via optional radio and downloaded onto a computer for detailed analysis. Maintenance and production personnel can download data and generate reports for better machine management. Data can be used to improve effectiveness of scheduled maintenance programs, maximize component life, improve machine availability, increase production and lower operating costs.

12

Gauge Cluster. Conveniently located gauge cluster maintains a constant display of vital machine functions, including: · engine coolant temperature

Categories. · Category I Machine or system needs attention. · Category II Requires operator to evaluate and correct situation before continuing work. [. . . ] ** Static tipping load and operating weight shown are based on standard machine configuration with 53. 5/85-57 tires, full fuel tank, coolant and lubricants. *** Measured 102 mm (4 in) behind tip of cutting edge with the bucket hinge pin as pivot point in accordance with SAE J732c.

22

994F Wheel Loader specifications

Changes in Standard Lift Specifications due to Tire Size

Dimensional changes Dump clearance at full lift and 45° discharge Reach at full lift and 45° discharge Reach with lift arms horizontal and bucket level Digging depth Overall length Overall height with bucket at full raise Total width over tires mm in mm in mm in mm in mm in mm in mm in 50/80-57 136 5 +118 +5 +118 +5 +136 +5 +105 +4 136 5 5305 209 52/80-57 143 6 +143 +6 +143 +6 +143 +6 +111 +4 143 6 5302 209 55/80R57 89 4 +68 +3 +68 +3 +89 +4 +70 +3 89 4 5509 217 53. 5/85-57 0 0 0 0 0 0 0 0 0 0 0 0 5460 214 58/85-57 +17 +0. 7 15 0. 6 15 0. 6 17 0. 7 12 0. 5 +17 +0. 67 5524 217

Weight changes Static tipping load straight Static tipping load at full 40° turn Operating weight kg lb kg lb kg lb 50/80-57 4234 9, 334 3738 8, 241 5388 11, 878 52/80-57 3339 7, 361 2953 6, 510 4256 9, 383 55/80R57 +50 +110 +44 +97 +64 +141 53. 5/85-57 0 0 0 0 0 0 58/85-57 +327 +721 +285 +628 +416 +917

994F Wheel Loader specifications

23

Operating Specifications High Lift

For machines equipped with 53. 5/85-57, 76 PR L-5 tires see additional tables for other tire sizes Coal Bucket (6200 mm/ 244 in) Straight Edge Coal Bucket Teeth & Segment 31 41 6200 20' 4" 27 35. 3 5974 19' 7" 2867 9' 5" 5819 19' 1" 78 3" 17 622 57' 10" 12 184 40' 0" 13 285 43' 7" 107 068 236, 044 91 770 202, 318 936 210, 421 197 904 436, 303

Narrow Bucket (5640 mm/222 in)

Wide Bucket (6200 mm/244 in)

m3 yd3 Width (§) mm ft/in Struck capacity (§) m3 yd3 Dump clearance at full lift mm and 45° discharge (§) ft/in Reach at full lift mm and 45° discharge (§) ft/in Reach with lift arms mm horizontal and bucket level ft/in Digging depth (§) mm in Overall length (§) mm ft/in Overall height with mm bucket at full raise (§) ft/in Loader clearance circle with mm bucket in carry position (§) ft/in Static tipping load straight** (§) kg lb Static tipping load kg at full 40° turn** (§) lb Breakout force*** (§) kN lb Operating weight** (§) kg lb

Rated capacity (§)

14 18. 5 5640 18' 6" 11 14. 4 6110 20' 0" 2632 8' 8" 5556 18' 2" 123 5" 17 396 57' 0" 11 058 36' 3" 12 959 42' 6" 108 695 239, 631 93 575 206, 297 1091 245, 475 194 634 429, 094

Spade Edge Rock Bucket Teeth & Segment 15 17 19. 5 22. 5 5640 5640 18' 6" 18' 6" 12 14 15. 7 18. 3 6110 6002 20' 0" 19' 8" 2632 2721 8' 8" 8' 11" 5556 5696 18' 2" 18' 8" 123 123 5" 5" 17 396 17 536 57' 0" 57' 6" 11 058 11 205 36' 3" 36' 9" 12 959 12 993 42' 6" 42' 7" 108 926 108 111 240, 140 238, 344 93 757 92 914 206, 699 204, 840 1091 1015 245, 475 228, 375 194 774 195 434 429, 403 430, 858

19 25 5640 18' 6" 15 19. 6 5895 19' 4" 2827 9' 3" 5846 19' 4" 123 5" 17 686 58' 0" 11 250 36' 11" 13 030 42' 10" 106 543 234, 887 91 399 201, 500 951 213, 793 196 514 433, 239

Spade Edge Rock Bucket Teeth & Segment 18 19 23. 5 25 6200 6200 20' 4" 20' 4" 14. 5 15 19 19. 6 6002 5902 19' 8" 19' 4" 2721 2839 8' 11" 9' 4" 5696 5850 18' 8" 19' 2" 123 123 5" 5" 17 536 17 690 57' 6" 58' 0" 10 960 10 975 36' 0" 36' 0" 13 249 13 285 43' 6" 43' 7" 105 978 104 795 233, 641 231, 033 90 871 89 753 200, 336 197, 871 1020 957 229, 305 215, 325 196 734 197 464 433, 724 435, 333

(§) Specifications rating conform to all applicable standards recommended by the Society of Automotive Engineers. SAE standard J732c governs loader ratings and is denoted in the chart by (§). * Dimensions are measured to the tip of the bucket teeth to provide accurate clearance data. [. . . ]