Detailed instructions for use are in the User's Guide.

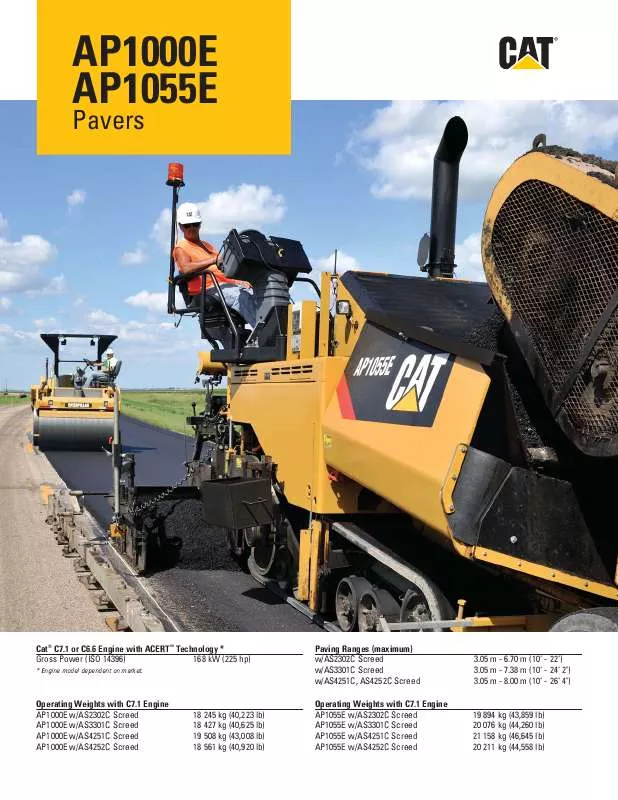

[. . . ] Exceptional visibility and comfort offered through dual swingout operating stations, fumes management, and quiet operation, ensure the crew continues its productivity throughout the day. Whether your choice of paver is equipped with the Mobil-TracTM undercarriage or wheels, both deliver the speed, mobility, and traction to excel on all types of job sites. [. . . ] The display lists service codes, providing quick reference. The ECMs are compatible with Cat Electronic Technician and easily connect to a laptop computer for fast technical support. Also, color-coded and numbered electrical wiring makes recognition easier when trying to locate the source of the fault code. Manual overrides located throughout the hydraulic system ensure the machine processes every bit of material should a problem occur. The overrides also simplify troubleshooting procedures by enabling the technician to eliminate functioning systems. ECMs communicate with Advisor Display ECMs compatible with Cat Electronic Technician Color-coded and numbered electrical wiring Manual overrides help diagnose functioning systems Pressure test ports and oil sampling ports simplify diagnosis of the hydraulic system Remote-mounted fluid drains deliver clean collection

PLAN AHEAD

Reduce service costs by planning ahead. Knowing which components need to be serviced and when the machine will need them allows service personnel to make the necessary arrangements to help you save money.

REBUILD PROGRAMS

Rebuild programs consisting of in-depth inspections of high wear items can be scheduled with your Cat Dealer in the off-season. These programs can prevent unscheduled downtime during the busy paving season.

MACHINE TRACKING MADE EASY

The optional Product Link System ensures maximum uptime and minimal repair costs by simplifying the tracking of equipment fleets. The system provides automatic machine location, hour updates, and diagnostic codes that can be used to schedule service requirements at more opportune times.

21

AS2302C

VERS-A-MATTM SCREED

The narrow, quick-reacting extenders make the AS2302C VERS-A-MATTM a perfect fit for applications that require frequent width changes.

TOP FEATURES

Front-mounted 229 mm (9") extenders require less mix to maintain the head of material in front of the screed Quick-reacting extenders optimize performance around obstacles Electrically heated screed plates offer cleaner working environment

APPLICATIONS

High and low production job sites Excels on variable width paving applications Parking lots, highways, streets, rural roads, overlays Extender Main Screed Extender

PAVING RANGES

Standard Paving Range: 3. 05 m - 5. 5 m (10' - 18') Maximum Paving Width: 6. 7 m (22') with bolt-on extensions

22

AS3301C

EXTEND-A-MATTM SCREED

Heavy-duty support tubes stabilize the extenders providing even material flow for high quality results on interstates, highways, airports and other high-production paving applications.

TOP FEATURES

Rear-mounted extenders allow mix to easily flow out to the end gates when increasing paving widths Stable support tubes promote wide width paving Electrically heated screed plates offer cleaner working environment

APPLICATIONS

Mainline paving applications Interstates, airports, highways, streets, rural roads, overlays Main Screed Extender Extender

PAVING RANGES

Standard Paving Range: 3. 05 m - 5. 94 m (10' - 19' 6") Maximum Paving Width: 7. 38 m (24' 2") with bolt-on extensions

23

AS4251C

VIBRATORY AND TAMPER BAR SCREED

Tamper bars combined with vibratory screed plates optimize mat density behind the screed.

TOP FEATURES

Balanced weight of 4000 kg (8, 819 lb) Analog control (potentiometer) for tamper speed, vibratory speed, and counterbalance pressure Double width hydraulic power extenders Tamper bar system delivers an adjustable range up to 1700 rpm with a stroke of 4 mm (0. 16") Adjustable vibratory screed plate range up to 3, 000 vpm 400 mm (15") dual main screed plate widths 15 mm (0. 60") screed plate thickness Low profile frame design for good visibility into the auger chamber Electric or LPG heated screed plates Foldable end gates (option) reduces transport width Power crown control (optional)

APPLICATIONS

Excels on thin lifts and provides the ability to eliminate a compactor due to higher densities behind the screed Interstates, airports, highways, streets, rural roads, overlays, reclaimed concrete

PAVING RANGES

Standard Paving Range: 3. 05 m - 5. 5 m (10' - 18') Maximum Paving Width: 8. 00 m (26' 4")

24

AS4252C

VIBRATORY AND TAMPER BAR SCREED

1. Heated End Gate (optional) Foldable End Gate (optional) Main Screed Controls Tamper Bar Eccentric Drive Tamper Bar Heating Element

8

10 9

6. Screed Plate Heating Element

3 7

2 1 4 5 6

TOP FEATURES

Balanced weight of 3200 kg (7, 055 lb) Equipped with LCD display Double width hydraulic power extenders Tamper bar system delivers an adjustable range up to 1700 rpm with a stroke of 4 mm (0. 16") Adjustable vibratory screed plate range up to 3, 000 vpm 330 mm (13") single main screed plate width 13 mm (0. 50") screed plate thickness Electrically heated screed plates and tamper bar deliver uniform heat distribution Heated end gates (option) prevent mix buildup Power crown control (standard) Foldable end gates reduces transport width

SCREED ADVISOR DISPLAY

Available in multiple languages Keeps operator informed of the following: - Temperature of each screed section - Tamper bar speed - Vibratory speed - Counter-balance pressure

APPLICATIONS

Excels on thin lifts, ability to eliminate a compactor due to higher densities behind the screed Interstates, airports, highways, streets, rural roads, overlays, reclaimed concrete (RCC)

PAVING RANGES

Standard Paving Range: 3. 05 m - 5. 5 m (10' - 18') Maximum Paving Width: 8. 00 m (26' 4") with bolt-on extensions

25

WIDE WIDTH PAVING PACKAGES

VERSATILE SCREED CONFIGURATIONS OPTIMIZE JOB SITE PERFORMANCE.

Screed packages contain all the components necessary to achieve the desired paving width and can include: screed extensions, auger extensions, auger support bearings, mainframe extensions and mainframe braces.

26

VIBRATORY SCREEDS

AS2302C SCREED EXTENSIONS

These extensions are available in 305 mm (1') and 610 mm (2') lengths. 305 mm (1') extensions are electrically heated 610 mm (2') extensions are electrically heated

R

VERS-A-MAT

AS2302C

3. 05 m (10') 5. 5 m (18') 6. 1 m (20') 6. 7 m (22')

AS3301C SCREED EXTENSIONS

EXTEND-A-MAT

R

AS3301C

These extensions are available in 305 mm (1') and 711 mm (2' 4") lengths. 3. 0 m (10') 305 mm (1') extensions are electrically heated 711 mm (2' 4") extensions are electrically heated with vibration 5. 9 m (19' 6") 6. 6 m (21' 6") 7. 4 m (24' 2")

VIBRATORY AND TAMPER BAR SCREEDS

AS4251C AND AS4252C SCREED EXTENSIONS

Bolt-on extensions are available in lengths of 0. 25 m (10") and 0. 75 m (30"). Quick-connect hydraulic couplings simplify attachment. [. . . ] Customer satisfaction continues to be our number one goal!

CAT DEALER SUPPORT

Cat Financial Services to meet all of your business needs 24 Hour Parts Support, get parts when and where you need them Project Consulting, optimize performance of your equipment Service Training, increase knowledge of machine components in order to minimize downtime Paver Operator Training (P. O. T. ), optimize machine performance

"UNTIL NOW, WE DIDN'T REALIZE WHAT GOOD CUSTOMER SUPPORT WAS. "

~ NEW CAT PAVING CUSTOMER

Optional Equipment

Auger and Mainframe Extensions Auxiliary Power Panel Cut-Off Shoe Decelerator Pedals Ecological Washdown System and Hose Reel Feeder Sensor (Mechanical or Sonic) Friction Steering (AP1055E) Front Wheel Assist or All-Wheel Drive (AP1000E) Grade and Slope Controls (Cat/Topcon) Hard Top Canopy High Intensity Discharge Lights (w/Canopy) Leveling Devices Lights (Working or Roading) Mobil-Trac Undercarriage Belt; smooth/treadbar (AP1055E) Oscillating Push Roller Power Folding Front Apron Power Mainframe Extensions Product Link Screed Extensions Tow-point Indicators (Upper) Track Plow (AP1055E) Truck Hitch Umbrella Up-time Kit Warning Beacon Wide Width Paving Packages Windshield (w/hard top canopy)

33

AP1000E Paver Specifications

J F K H A B C D E G I

Dimensions

A Tractor length w/push roller B Length with push roller and AS2302C screed w/walkway up Length with push roller and AS2302C screed w/walkway down Length with push roller and AS3301C screed Length with push roller and AS4251C screed Length with push roller and AS4252C screed C Wheel gauge width (outside to outside) D Transport width with screed end gates (hopper raised) Transport width without screed end gates (hopper raised) E Tractor operating width (hopper lowered) F Operating height G Transport height with fumes stack and seat lowered H Truck entry height (apron) I Truck entry width J Hopper length K Deck Height 4. 95 m (16' 3") 5. 46 m (17' 11") 5. 80 m (19') 6. 61 m (21' 7") 6. 52 m (21' 4") 6. 63 m (21' 8") 2. 87 m (9' 5") 3. 24 m (10' 8") 3. 00 m (9' 10") 3. 52 m (11' 7") 3. 72 m (12' 2") 2. 85 m (9' 4") 585 mm (23") 3. 52 m (11' 7") 2. 10 m (6' 11") 1. 77 m (5' 10")

Weights

AP1000E (Tractor only) w/AS2302C w/AS3301C w/AS3301C w/C6. 6 engine w/AS4251C w/AS4251C w/C6. 6 engine w/AS4252C w/AS4252C w/C6. 6 engine 15 160 kg (33, 352 lb) 18 245 kg (40, 223 lb) 18 427 kg (40, 625 lb) 18 660 kg (41, 138 lb) 19 508 kg (43, 008 lb) 19 742 kg (43, 524 lb) 18 561 kg (40, 920 lb) 18 795 kg (41, 436 lb)

Paving Range

w/AS2302C w/AS3301C w/AS4251C w/AS4252C Max Paving Depth 3. 05 m - 6. 70 m (10' - 22') 3. 05 m - 7. 38 m (10' - 24' 2") 3. 05 m - 8. 00 m (10' - 26' 4") 3. 05 m - 8. 00 m (10' - 26' 4") 305 mm (12")

Powertrain

Cat C7. 1 or C6. 6 ACERT Engines Speeds: Paving w/tamper bar screed Travel 168 kW (225 hp) 61 mpm (200 fpm) 25 mpm (82 fpm) 20 km/hr (12 mph)

Miscellaneous

Fuel Tank Capacity Hopper Capacity* Electrical System Generator Size

* Includes tunnels

348 L (92 gal) 7. 1 m3 (251 ft3) 24 V, 105A alternator 25 kW or 35 kW

34

AP1055E Paver Specifications

J F K H A B C D E G I

Dimensions

A Tractor length w/push roller B Length with push roller and AS2302C screed w/walkway up Length with push roller and AS2302C screed w/walkway down Length with push roller and AS3301C screed Length with push roller and AS4251C screed Length with push roller and AS4252C screed C Track gauge width (outside to outside) D Transport width with screed end gates (hopper raised) Transport width without screed end gates (hopper raised) E Tractor operating width (hopper lowered) F Operating height G Transport height with fumes stack and seat lowered H Truck entry height (apron) I Truck entry width J Hopper length K Deck Height 4. 95 m (16' 3") 5. 46 m (17' 11") 5. 80 m (19') 6. 61 m (21' 7") 6. 52 m (21' 4") 6. 63 m (21' 8") 2. 72 m (8' 11") 3. 24 m (10' 8") 3. 00 m (9' 10") 3. 60 m (11' 10") 3. 73 m (12' 3") 2. 87 m (9' 5") 581 mm (23") 3. 52 m (11' 7") 2. 10 m (6' 11") 1. 79 m (5' 11")

Weights

AP1055E (Tractor only) w/AS2302C w/AS3301C w/AS3301C w/C6. 6 engine w/AS4251C w/AS4251C w/C6. 6 engine w/AS4252C w/AS4252C w/C6. 6 engine 16 810 kg (36, 982 lb) 19 894 kg (43, 859 lb) 20 076 kg (44, 260 lb) 20 310 kg (44, 776 lb) 21 158 kg (46, 645 lb) 21 392 kg (47, 161 lb) 20 211 kg (44, 558 lb) 20 445 kg (45, 074 lb)

Paving Range

w/AS2302C w/AS3301C w/AS4251C w/AS4252C Max Paving Depth 3. 05 m - 6. 70 m (10' - 22') 3. 05 m - 7. 38 m (10' - 24' 2") 3. 05 m - 8. 00 m (10' - 26' 4") 3. 05 m - 8. 00 m (10' - 26' 4") 305 mm (12")

Powertrain

Cat C7. 1 or C6. 6 ACERT Engines Speeds: Paving w/tamper bar screed Travel 168 kW (225 hp) 61 mpm (200 fpm) 25 mpm (82 fpm) 14. 5 km/hr (9 mph)

Miscellaneous

Fuel Tank Capacity Hopper Capacity* Electrical System Generator Size

* Includes tunnels

348 L (92 gal) 7. 1 m3 (251 ft3) 24 V, 105A alternator 25 kW or 35 kW

35

AP1000E AND AP1055E PAVER

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at www. cat. com © 2011 Caterpillar All Rights Reserved Materials and specifications are subject to change without notice. Featured machines in photos may include additional equipment. [. . . ]