Detailed instructions for use are in the User's Guide.

[. . . ] This is accomplished with the MEUI fuel system, which strikes the proper balance between the precision of the electronic control system and the simplicity of mechanically controlled unit fuel injectors. The result is more productivity and lower fuel consumption.

Air-to-Air Aftercooling

Air-to-air aftercooling provides cooled compressed air to the engine intake manifold, thus reducing emissions and maximizing fuel efficiency.

Overhead Cams

Two, single overhead cams are driven by gears on the flywheel end of the engine. Placing them on the flywheel end significantly reduces noise and vibration. To reduce wear, two pendulum absorbers are mounted at the front of the camshafts. [. . . ] The torque converter shields the driveline from sudden torque shocks and vibration.

Planetary Power Shift Transmission

Three speeds forward and three speeds reverse, utilizing large diameter, high-capacity, oil-cooled clutches. · · · · Modulation system permits fast speed and direction changes. Modular transmission and bevel gear slide into rear case for servicing ease, even with ripper installed. Oil-to-water cooler for maximum cooling capacity. Forced oil flow lubricates and cools clutch packs to provide maximum clutch life.

Electronic Clutch Pressure Control

Provides smoother shifting by modulating individual clutches.

Power Shift with Steering Clutch and Brake

lbs × 1000 225 200 175 N× 1000 1100 1000 900 800 700 600 125 100 75 50 25 0 500 400 300 200 100 0 0 0 1 2 2 4 3 6 4 8 5 6 10 7 12 8 14 km/h mph

Steering Clutch and Brake

Fade resistant and adjustment free. The multi-disc, oil-cooled steering clutches are hydraulically applied and electronically controlled. The brakes are applied by springs and hydraulically released for safe and reliable braking performance.

1

Drawbar Pull vs. Ground Speed

As loads on the tractor increase, the D10T offers unmatched lugging capability and smooth shifting as the need occurs to change gears under varying loads. The 3-speed forward, 3-speed reverse transmission offers excellent runout speeds.

Drawbar Pull

150

2

Elevated Final Drives

Isolated from ground and equipment induced impact loads for extended power train life. Crown-shaved drive gears provide smooth, quiet, low maintenance operation. Splash lubrication and Duo-ConeTM Seals extend service life.

3

Modular Power Train

The modular power train design permits quick removal and installation of major components such as the engine, transmission and final drives.

Speed

1 1st Gear Forward 2 2nd Gear Forward 3 3rd Gear Forward

6

Undercarriage

Suspended Undercarriage Design

Designed for optimized machine balance and the best performance.

Absorbs impact loads, to reduce the shock loads transferred to the undercarriage, by up to 50%.

Bogie Suspension

Bogie suspension conforms closely to the ground providing up to 15 percent more ground contact, especially in uneven terrain. Higher traction means less slippage, better balance, and a smoother ride.

Integrated Carrier Roller Mount

The carrier roller mount is cast into the track roller frame making it easier to add the optional carrier roller in the field, if conditions require it.

Rollers and Idlers

Feature symmetric Duo-Cone seals for long sealing life to prevent oil loss and dirt entry. Toric rings maintain performance over a wide range of temperatures.

Roller Frames

Roller frames are tubular to resist bending and twisting, with added reinforcement.

Positive Pin Retention (PPR) Sealed and Lubricated Track

Designed for high-impact and high load applications, the Caterpillar design locks the link to the pin.

Sprocket Segments

Made exclusively of Cat Tough SteelTM for longer wear life and precision machined for fit.

Track Shoes

Track shoes are available in a variety of sizes and styles to match the working conditions.

7

Structure

Engineered for maximum production and service life.

Mainframe Strength

The D10T mainframe is built to absorb high impact shock loads and twisting forces.

Frame Rails

Full box section, designed to keep components rigidly aligned.

Heavy Steel Castings

Add strength to the main case, equalizer bar saddle, front cross member and tag-link trunnion.

Top and Bottom Rails

Continuous rolled sections, with no machining or welding, to provide superior mainframe durability.

Main Case

Elevates the final drives well above the ground level work area to protect them from impact loads, abrasion and contaminants.

Pivot Shaft

The D10T pivot shaft runs through the mainframe and connects to the roller frames, allowing independent oscillation. The full-length pivot shaft distributes impact loads throughout the case, reducing the bending stress on the case.

Equalizer Bar

The equalizer bar features limited slip seals and an oillubricated joint for better oil flow. Remote lube passages simplify maintenance. Large forged pads reduce wear on the mainframe and extend sealed joint life.

Engine and Radiator Guard Mount

The new fabricated common front engine and rear radiator mount feature heavy castings.

Tag-Link

The Tag-Link brings the blade closer to the machine for more precise dozing and load control. The Tag-Link design provides solid lateral stability and better cylinder positions for constant break out force, independent of blade height.

8

Work Tools

Bulldozers

Provide the flexibility to match the machine to the job.

All blades feature a strong box-section design that resists twisting and cracking. It provides updates on service meter hours, machine condition and machine location, as well as integrated mapping/route planning. Built-in flexibility allows for future technology development.

10

Customer Support

Machine Selection

Make detailed comparisons of the machines you are considering before you buy. What is the cost of preventive maintenance?What is the true cost of lost production?Your Cat Dealer can give you answers to these very important questions.

The Cat Dealer network keeps your fleet up and running.

Purchase

Consider the financing options available as well as day-to-day operating costs. [. . . ] Add 840 kg (1, 852 lb) for 10SU ABR blade. Add 1629 kg (3, 591 lb) for 10U ABR blade. **Total Operating Weight: Includes hydraulic controls, blade tilt cylinder, coolant, lubricants, 100% fuel, ROPS, FOPS cab, Blade, Single-Shank Ripper, 610 mm (24 in) ES shoes, and operator.

13

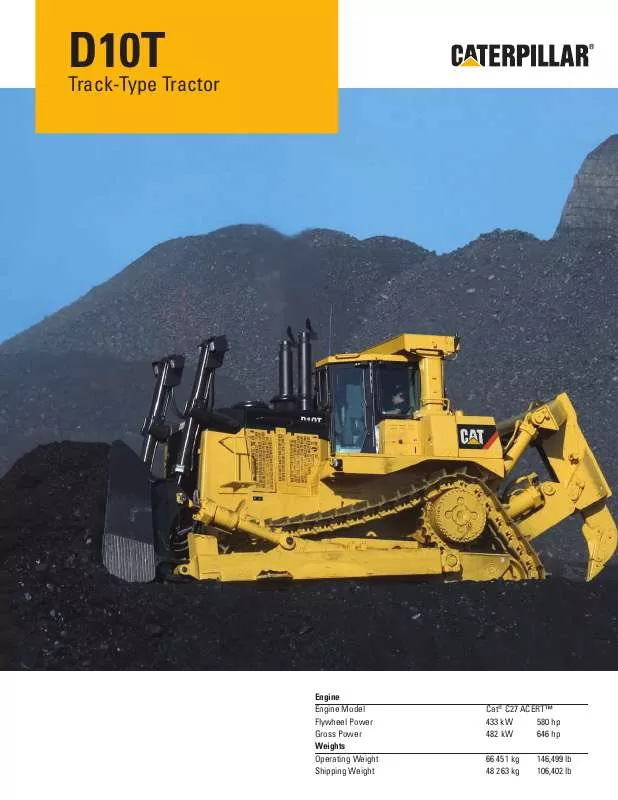

D10T Track-Type Tractor Specifications

Dimensions

All dimensions are approximate.

6 7 5 8 9 10, 11, 12 13, 14 15, 16 17

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Ground Clearance Track Gauge Width without Trunnions (Standard Shoe) Width Over Trunnions Height (FOPS Cab) Height (Top of Stack) Height (ROPS/Canopy) Drawbar Height (Center of Clevis) Length of Track on Ground Overall Length Basic Tractor Overall Length Basic Tractor (with Drawbar) Overall Length Basic Tractor with Winch Length with SU-blade Length with U-blade Length with Single-Shank Ripper Length with Multi-Shank Ripper Overall Length (SU Blade/SS Ripper) 664 mm 2550 mm 3292 mm 3736 mm 4098 mm 4505 mm 4354 mm 864 mm 3872 mm 5339 mm 5659 mm 5744 mm 7416 mm 7750 mm 7081 mm 7241 mm 9158 mm 26. 1 in 100. 4 in 129. 6 in 147. 1 in 161. 3 in 177. 4 in 171. 4 in 34. 0 in 152. 4 in 210. 2 in 222. 8 in 226. 1 in 292. 0 in 305. 1 in 278. 8 in 285. 1 in 360. 6 in

1 2 3, 4

14

D10T Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

ELECTRICAL Alternator, 95-amp Back-up alarm Batteries, 12-volt (2), 200 amp-hour, maintenance free Converter, 12-volt, 10-amp Diagnostic connector Horn, forward warning Light, engine compartment Lighting system, Halogen (2 forward, 2 rear) Starting receptacle OPERATOR ENVIRONMENT Advisor-electronic monitoring system Armrest, adjustable Cab, FOPS Controls, electronic implement Decelerator pedal Finger Tip Control (FTC) steering Governor switch, electronic Heater and ventilation Hydraulic system, electronically controlled for bulldozer control Mirror, rearview Radio ready Seat, adjustable contour suspension (gray fabric) Seat belt, retractable 76 mm (3 in) Steps, heavy-duty and Handles Wipers, intermittent UNDERCARRIAGE 610 mm (24 inch) extreme service grouser with sealed and lubricated PPR track (44 section) Rollers and idlers, lifetime lubricated Sprocket rim segments, replaceable Suspension-type undercarriage, Eight-roller tubular track roller frame Track adjusters, hydraulic Track guides Two-piece master links POWER TRAIN C27 with ACERT Technology 24-volt electric start Advanced Modular Cooling System Aftercooler, remote air-to-air Air filters, dual with precleaner Controlled throttle shifting Coolant, extended life Directional shift management Ether starting aid, automatic Fan, suction with hydraulic demand drive Fuel priming pump, electric Mufflers, dual, with rain cap Parking brake, electronic Prescreener Separator, water/fuel Thermal shields Torque divider Transmission, powershift, ECPC, (3F/3R speeds) Four planet, double-reduction planetary final drives OTHER Auto-blade assist (for dual tilt) CD ROM parts book Ecology drains Engine enclosures Grade control ready Guards: Bottom, hinged extreme service Crankcase, hinged extreme service Pivot shaft and seals Radiator, with towing device Implement gear pump compatible for arctic conditions Product Link ready Vandalism protection

15

D10T Optional Equipment

Optional equipment may vary. [. . . ]