Detailed instructions for use are in the User's Guide.

[. . . ] · Wide door openings for getting in and out of the cab easily. · Clear view to the blade corners and bottom cutting edge, especially important in fine grading, working against foundations and curbing. · Operator sound level has been lowered inside the cab 4 dB(A) to an industry leading 80 dB(A) ANSI/SAE J1166 OCT 98. This provides a quiet, comfortable working environment reducing operator fatigue and increasing their productivity.

Seat-Mounted Joystick Controls

For optimum comfort and precise control, the D3K features ergonomically designed seat-mounted controls. [. . . ] Segmented sprockets are easy to replace and less expensive than replacing the complete sprocket hub.

Choice of Track Frame Configurations

Track frames are available in extra long (XL) or low ground pressure (LGP) configurations. XL undercarriage provides increased ground contact area and flotation, superior balance and excellent finish grading. In addition, the LGP version also features a wider track shoe, increasing ground contact area for optimum flotation and stability on sloping and finish grading jobs. As an additional choice, the LGP undercarriage on the D3K is available with 762 mm (30 in) shoes.

SystemOne Cartridge SystemOne Center Tread Idler

5

AccuGradeTM Systems

Grade with increased accuracy.

Caterpillar is revolutionizing the way to move material with new technology solutions for earthmoving machines solutions that provide greater accuracy, higher productivity, lower operating costs and greater profits. The AccuGrade System is designed and integrated into the machine and hydraulic systems to create an automated blade control system that allows operators to grade with increased accuracy. The system uses machine-mounted sensors to calculate precise blade slope and elevation information.

AccuGrade Laser

AccuGrade Laser uses a laser transmitter and receiver for precise grade control. A laser transmitter on the worksite creates a constant grade reference over the work area. A digital laser receiver mounted on the machine captures the laser signal. The system calculates the blade adjustments necessary to achieve grade, makes automatic elevation adjustments typically performed by the operator and provides automatic blade control. Automated blade control lets you achieve grade faster and in fewer passes, reducing the need for traditional survey stakes or grade checkers. The system also calculates cut/fill requirements for manual blade control. Work is completed faster, more accurately and with less manpower. AccuGrade Laser is well suited for flat work such as concrete pads and driveways.

AccuGrade GPS

AccuGrade GPS computes the machine positioning information and compares the position of the blade relative to the design plan. Information is provided to the operator via an in-cab display showing blade elevation, necessary cut/fill to achieve grade, blade position on the design surface and a graphical view of the design plan with machine location. AccuGrade GPS puts all the information the operator needs to complete the job in the cab for a greater level of control. Vertical and horizontal guidance tools visually guide the operator to the desired grade. Automated features allow the hydraulic system to automatically control blade adjustments to move the blade to grade. The operator simply uses the light bars to guide the machine for consistent, accurate grades and slopes, increasing productivity with less fatigue. AccuGrade GPS is best used for cut and contour jobs.

AccuGrade Laser Display

AccuGrade GPS Display

AccuGrade Monitor

Caterpillar is the first to integrate this system and its monitor into the machine's dash for easy viewing during operation. The AccuGrade monitor is conveniently located, allowing the operator to view system information while keeping a straight line of sight to the blade corners.

6

Blade and Attachments

Cat work tools can handle tough dozing applications.

VPAT Blade

The VPAT blade is specifically designed for finish grading, backfilling ditches, cutting V ditches, windrowing, fill spreading, medium land clearing and heavy dozing. Built for rugged strength and durability, this 6-way blade allows for adjustable angle, tilt and pitch. Visibility to the blade corners and cutting edge is improved. [. . . ] Consult your Caterpillar dealer for details.

ELECTRICAL Horn Backup alarm Diagnostic connector Heavy duty 750 CCA batteries Alternator, 12V, 120 Amp, heavy duty brushless 12V Starter OPERATOR ENVIRONMENT ROPS/FOPS cab with sliding side windows and air conditioning Cat C500 comfort cloth air suspended seat with adjustable armrests 76 mm (3 inch) retractable seat belt Adjustable seat-mounted, electro-hydraulic controls Foot rests Compact Instrument Cluster including: · Gauges for engine coolant temperature, hydraulic oil temperature and fuel level · 12 indicators · Digital display (ground speed, engine RPM, hour meter) Rotary throttle switch Travel speed limiter Independent forward/reverse speed settings Single pedal combining deceleration and braking functions Rearview mirror 12V power port Coat hook Storage compartment Cup holder Heavy duty rubber floor mat Windshield washers and wipers, front and rear POWER TRAIN Caterpillar C4. 4 ACERT diesel engine, turbocharged Aluminum bar plate cooling system (radiator, power train) Blower fan Air cleaner with precleaner, automatic dust ejection and under-hood intake Fuel priming pump with integrated fuel/water separator Dual path, closed-loop hydrostatic transmission Under-hood muffler ANTIFREEZE Extended life coolant, 37° C (35° F) HYDRAULICS Hydraulics, 3 valve UNDERCARRIAGE SALT Undercarriage Lifetime lubricated track rollers (6) and idlers Carrier rollers Tracks, 41 sections: · XL configuration 406 mm (16 in) · LGP configuration 635 mm (25 in) Hydraulic track adjusters OTHER STANDARD EQUIPMENT C-Frame, VPAT, hydraulic cylinders and lines Fuel tank Heavy duty crankcase guard Lockable engine enclosures Idler guards Radiator guard and grill Front pull device Rigid drawbar S·O·SSM ports (engine, power train and hydraulics)

12

D3K Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

ELECTRICAL Integrated two front halogen lights, one rear halogen light Integrated four front halogen lights, two rear halogen lights POWER TRAIN Drive auxiliary Installation, winch UNDERCARRIAGE TRACK PAIRS, XL · Track, 406 mm (16 in) MS SystemOneTM · Track, 356 mm (14 in) TG SALT TRACK PAIRS, LGP · Track, 635 mm (25 in) MS SystemOneTM · Track, 635 mm (25 in) Self cleaning SALT · Track, 635 mm (25 in) Self cleaning SystemOneTM OPERATOR ENVIRONMENT Cab Cab, polycarbonate windows, 360 degree guarding protection Seat, cloth, air suspension, heated Radio, AM/FM, CD player REAR ATTACHMENTS Drawbar, towing Mounting, winch Ripper, parallelogram, includes three shanks and teeth FIELD INSTALLED ATTACHMENT Winch, hydrostatic HYDRAULICS Hydraulics, 4 valve for use with ripper Hydraulics, 4 valve for use with winch GUARDS Guard, rear, heavy duty Grill, radiator, heavy duty Guard, track guiding, center Guard, track guiding, full length Screen, rear, cab Screen, side, cab Screen, rear, canopy Screen, front and sides, canopy Sweeps, front Sweeps, rear BLADES VPAT XL blade VPAT LGP blade VPAT Intermediate blade ANTIFREEZE Coolant, ext. life, 50° C (58° F) OTHER ATTACHMENTS Enclosure, sound suppression Machine Security System Caterpillar Product Link 321 Caterpillar Product Link 121 STARTING AIDS Heater, engine, coolant, 120V Starting aid, ether MACHINE CONTROL AND GUIDANCE Installation, AccuGrade ready REAR ATTACHMENT CONTROL Control, ripper Control, winch Control, ripper and winch

13

Notes

14

15

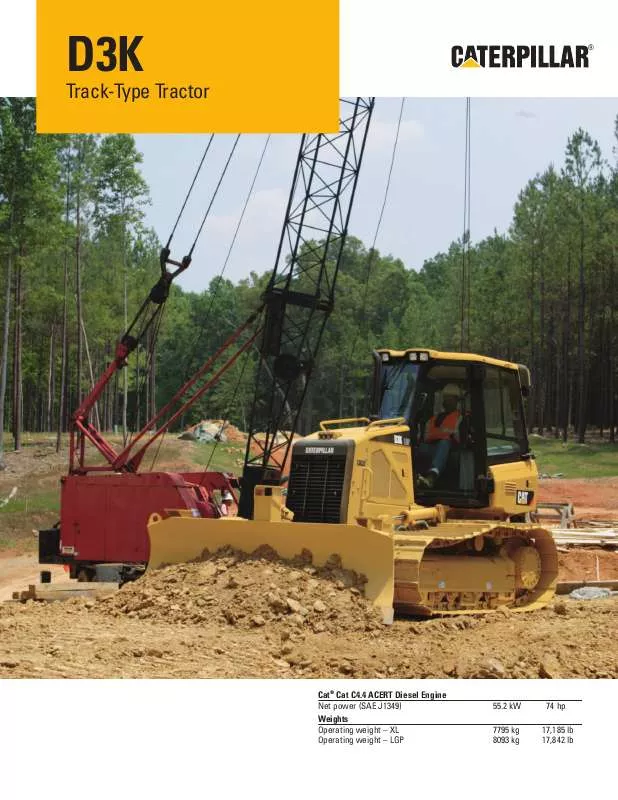

D3K Track-Type Tractor

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at www. cat. com © 2007 Caterpillar Inc. All rights reserved Printed in the U. S. A. [. . . ]