Detailed instructions for use are in the User's Guide.

[. . . ] · Differential steering turns the machine by speeding up one track and slowing the other while maintaining full power to both. Steering modulation is finely tuned for precise control. Regardless of ground conditions, steering is consistent because power is maintained to both tracks during operation.

· ·

Engine

Emission reduction technology.

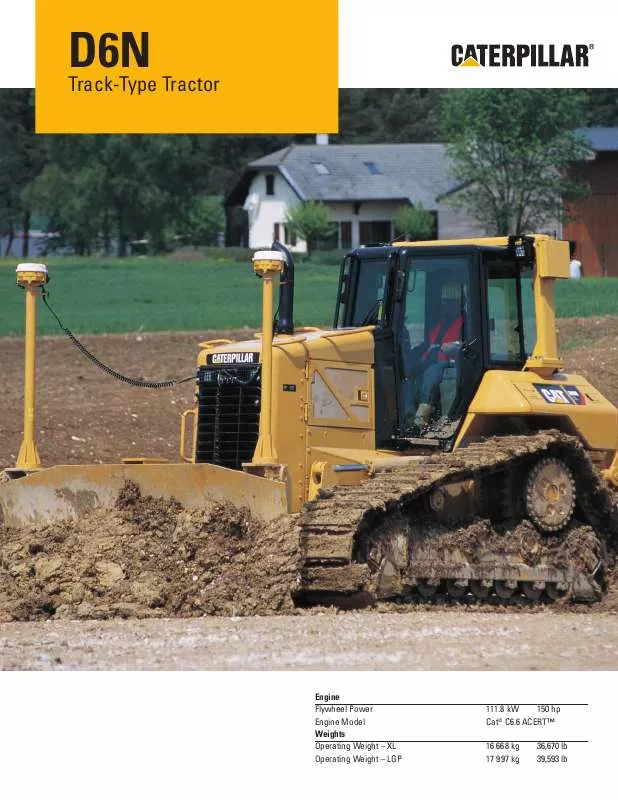

Cat® C6. 6 Engine with ACERTTM Technology

The Cat® C6. 6 is a 6. 6 liters (403 in3) displacement, six cylinder, inline configured engine equipped with a Caterpillar Common Rail fuel System. It uses ACERT Technology, a series of Caterpillar engineered innovations that provide advanced electronic control, precision fuel delivery and refined air management, resulting in outstanding performance and lower emissions. [. . . ] Mounting brackets in the cab secure the in-cab display. Plug-in points inside the cab and on the front of the machine make it easy to install electronic components.

AccuGrade GPS System

The AccuGrade Global Positioning System (GPS) is the best solution when the construction site involves contours, rather than single or dual slope planes. A GPS system compares the blade position to a three-dimensional computerized job site plan and signals the operator or hydraulic system to raise or lower the blade to achieve the design requirements.

AccuGrade ATS System

The AccuGrade ATS system tracks blade positioning and provides three dimensional controlling capability for precise elevation adjustment, improved accuracy and dynamic tracking.

AccuGrade Laser System

The laser system is ideal for fine grading sites with flat, single slope or dual slope surfaces such as industrial, commercial and residential building sites.

AccuGrade Monitor

The in-cab display with easy-to-read grade indicators and real time operator information provide the operator with all AcuuGrade system information. The display is designed for reliable performance in extreme operating conditions including shock, dust and moisture.

6

SystemOneTM Undercarriage

Lower owning and operating costs.

SystemOneTM Undercarriage

Exclusively for Caterpillar machines, the design extends system life and reduces operating costs.

Undercarriage Arrangements

XL (Extra Long) arrangement · · · · Forward idler position provides more track on the ground and to the front of the tractor. It provides optimal balance, superior traction and blade control for finish grading. Long roller frame provides good flotation in soft underfoot conditions. Specially designed to work in soft and spongy conditions. Wide track shoes, a longer track frame and a wider gauge increase track contact area and reduce ground pressure for excellent flotation.

LGP (Low Ground Pressure) arrangement

Equalizer Bar

The pinned equalizer bar gives the roller frames the ability to oscillate up or down to better match ground contours while providing maximum traction and operator comfort.

7

Blades and Attachments

Cat Work Tools are built to handle the toughest dozing applications.

Variable Pitch Power Angle and Tilt Blade (VPAT)

The VPAT blade gives the operator the ability to hydraulically adjust the blade lift, angle and tilt from the operator's station. · · · Manually adjustable blade pitch for optimum performance. Top corners of the blade are clipped for better operator viewing area. C-Frame is solidly pinned to the mainframe for good blade control and eliminates blade motion due to track oscillation or side forces.

Foldable Blade

Designed to facilitate transportation without removing the blade, the foldable blades reduced overall shipping width of the machine. The blade can be folded by hand by one person without the need for tools, and each foldable blade includes the mounting brackets for AccuGrade masts.

Drawbar

The D6N can be equipped with a drawbar for pulling work tools such as disks, compactors, chopper wheels and retrieval of other equipment.

Multi-Shank Ripper

The multi-shank parallelogram ripper lets you choose one, two or three shanks depending on job conditions. Curved or straight ripper shanks are available.

Winch

Standard and slow-speed winches are available to match the application requirements. · · · Integrated electronic controls for both clutch and brake functions improve winch performance. Clutch engagement and brake release are automatically synchronized for smooth operation. Winch components can be serviced with winch mounted on tractor.

Check with your Caterpillar Dealer for details.

Forestry Sweeps

In forestry and land clearing applications where limbs and debris can damage a machine, optional sweeps are available for the D6N. Sweeps help to shield critical components on the tractor such as hydraulic lines, exhaust stacks, cab windows and lights from damage.

8

Value Packages

Get more for less.

Ripper Ready Package

Includes factory-installed hydraulics, wiring and ripper controls in a customized ripper control console.

Winch Ready Package

Includes factory-installed wiring and winch controls in a customized winch control console.

Heavy Duty Guard Package

Includes heavy duty guards for both the fuel tank and the crankcase, and a heavy duty hinged, louvered radiator grill with latch.

Cold Weather Package

Includes a coolant heater and high-capacity (1400 CCA) heavy-duty batteries for improved cold start capability.

Maintenance Package

Includes fast fuel and high speed oil change capability.

Semi-Universal Blade Package (Cab)

Built for tough applications where penetration and blade side loading are important. The design of the SU blade makes it excellent for aggressive dirt penetration and loading materials. The blade wings are designed for superior load retention.

Contact custom products for waste handling, forestry and other specific application requirements.

9

Simplified service and maintenance requirements.

Serviceability

Easy Access

Hinged engine doors provide easy access to secondary fuel filters, oil filters, engine oil filler tube, engine air filter, and the A/C compressor. Service doors provide easy access to the battery disconnect switch, hydraulic taps, transmission oil tank filler cap, windshield washer tank and batteries, emergency shut off switch, electronic control module, and the hydraulic case drain filter. [. . . ] * Weight: Includes pump, operator controls, oil, mounting brackets and spacers.

12

Dimensions

(approximate)

3

7

9 1 2

4 5 6

8

Tractor Dimensions XL 1 Track gauge 2 Width of tractor With the following attachments: Standard shoes without blade Narrow shoes without blade Standard shoes with VPAT blade fully angled 3 Machine height from tip of grouser: With the following equipment: ROPS canopy ROPS cab 4 Drawbar height (center of clevis) From ground face of shoes 5 Length of track on ground 6 Length of basic tractor (with drawbar) With the following attachments, add to basic tractor length: Ripper PA55 winch VPAT blades, straight VPAT blade, angled 25° SU blade 7 Height over stack from tip of grouser 8 Height of grouser 9 Ground clearance from ground face of shoe (per SAE J1234) 1890 mm 74. 4 in 2160 mm LGP 85 in

2500 mm 2450 mm 2972 mm

98. 4 in 96. 5 in 117 in

3000 mm 2870 mm 3706 mm

118 in 113 in 146 in

3040 mm 3095 mm 595 mm 2611 mm 3740 mm 1026 mm 381 mm 1163 mm 1787 mm 1417 mm 2979 mm 66 mm 394 mm

119. 7 in 121. 9 in 22. 2 in 102. 8 in 147. 2 in 40. 4 in 15 in 45. 8 in 70. 4 in 55. 8 in 117. 3 in 2. 6 in 15. 5 in

3144 mm 3200 mm 710 mm 3113 mm 4165 mm 1026 mm 381 mm 1204 mm 2125 mm -- 3083 mm 57 mm 507 mm

123. 8 in 126 in 28 in 122. 56 in 164 in 40. 4 in 15 in 47. 4 in 83. 7 in 121. 4 in 2. 2 in 20. 0 in

13

D6N Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details

ELECTRICAL Horn Hour meter Back-up alarm 12-volt converter, 10-amp Diagnostic connector 950 CCA class 31 batteries Integrated lights (4 front, 2 rear) with protective screen 95A HD brushless alternator (24 V) 24V electric starter OPERATOR ENVIRONMENT ROPS/FOPS cab with integrated A/C Seat, air suspension, cloth for cab Seat belt, retractable 76 mm (3 in) Adjustable armrest Foot rests for slope work Five gauge cluster (engine coolant, transmission oil, hydraulic oil, fuel level, and engine RPM display/gear display) Electronically programmable gear selector Electronic engine air cleaner service indicator Electronic water-in-fuel sensor service indicator Electro-hydraulic implement control Electro-hydraulic tiller bar differential steering control Product Link ready Two 12V power ports 12V radio ready (plug and play) Storage compartment Cup holder Coat hook Rearview mirror POWER TRAIN C6. 6 Caterpillar ACERT diesel engine with Caterpillar Common Rail fuel system, ADEM A4 Electronic Control Module, and a air-to-air aftercooling Single poly-vee belt with auto belt tensioner Starting aid ether injection 3000 meter altitude operation capability without derating Fan, direct drive Aluminum bar plate cooling system (radiator, power train, aftercooler) Steel tube-fin oil cooler (differential steering) Air cleaner with integrated pre-cleaner, automatic dust ejector and under hood air intake Electrical fuel priming pump with integrated fuel/water separator Engine decelerating function (toggle switch and pedal engine speed control) 3 speed planetary powershift transmission with torque converter System MVP: Multiple speed functionality providing 5 discrete ground speed selections and electronic control enhancements for the transmission/engine system Controlled throttle shifting with automatic load compensation, selectable automatic down shift and kick down transmission control Auto-shift (1. 5F 2. 5R, 2. 5F 2. 5R) Selectable differential steering HYDRAULICS Three valve hydraulics for VPAT dozer Load sensing hydraulics UNDERCARRIAGE SystemOneTM Undercarriage Center tread idler Lifetime lubricated track rollers (7 XL and 8 LGP) and idlers Carrier rollers Tracks 40 section 610 mm (24") Extreme Service (ES) for XL Tracks 46 section 840 mm (33") Moderate Service (MS) for LGP Hydraulic track adjusters Front and rear track guiding guards, Moderate Service (MS) for LGP Replaceable sprocket rim segments OTHER STANDARD EQUIPMENT C-Frame, cylinders (VPAT) and lines Extended service intervals (500 hrs engine, 1, 000 hrs power train) Crankcase guard Ecology drains (engine, power train, hydraulic oil) Scheduled oil sampling ports (engine, power train, hydraulics, and engine coolant) Coolant sampling port Centralized remote mounted pressure taps for easy access and diagnostics Implement oil filter Front pull device Hinged, louvered radiator grill Lockable engine enclosures Rigid drawbar 3000 meter altitude operation capability w/o de-rating ANTIFREEZE Extended life coolant (37° C/35° F) Cat HYDO Advanced 10

14

D6N Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details

ELECTRICAL Rotating beacon GUARDS Guard, front lines Guard, track guiding, MS Guard, track guiding, center, XL Guide/Guard, track, HD Screen, protective, cab Screen, protective, canopy POWER TRAIN Grid sandblast Fan, direct drive, reversing Precleaner, turbine with screen Radiator, trash resistant UNDERCARRIAGE TRACK PAIRS, XL (40 sec) Track, 560 mm (22"), ES, XL Track, 610 mm (24"), MS, XL Track, 610 mm (24"), ES, Center Hole, XL TRACK PAIRS, LGP (46 sec) Track, 840 mm (33"), ES, LGP Track, 860 mm (34"), ES, LGP OPERATOR ENVIRONMENT Canopy, heated Machine security system HYDRAULICS Hydraulic Oil, Biodegradable BLADES Blade, VPAT, AccuGrade ready, XL Blade, VPAT, AccuGrade ready, LGP Blade, AccuGrade ready, Foldable, XL Blade, AccuGrade ready, Foldable, LGP Blade, VPAT XL Foldable Fine Grading AccuGrade REAR ATTACHMENT Winch preparation Ripper, multi-shank Teeth, curved shank ripper

MACHINE CONTROL AND GUIDANCE Installation, AccuGrade ready Cab/Canopy OTHER ATTACHMENTS Sound suppression, exterior Doors, engine, SU Enclosure engine, SU Enclosure engine perforated, SU Enclosure engine perforated, VPAT PTO Relocation filter ANTIFREEZE Coolant, ext. life, 50° C (58° F) SPECIAL ARRANGMENTS Forestry arrangement, XL/LGP Waste handling arrangements XL/LGP FIELD INSTALLED ATTACHEMENTS PA 55 winch slow and standard speed Radio, 12 V AM/FM CD and MP3

D6N VALUE PACKAGES Ripper, Ready Package Hydraulics 4 Valve (6VPAT) Cover Console (Ripper Control Cab) Winch Ready Package Tractor Winch Ready Cover Console (Winch Control Cab) Maintenance Package Tank Fuel Fast Fill Ready High Speed Oil Change Engine Cold Weather Package 120V Heater Engine Coolant (120V) Battery Heavy Duty Cold Weather Package 240V Heater Engine Coolant (240V) Battery Heavy Duty Heavy Duty Guard Package Guard Crankcase HD Guard Fuel Tank Grill Front Louvered HD Protection Package Cab Screen Protective (Cab) Sweeps Cab Mounted Protection Package Canopy Screen Protective (Canopy) Sweeps Canopy Mounted Forestry/Exploration Package Fan Reversible (Direct Drive) Roof Gp Forestry Forestry Ar Complete 6VPAT XL Fine Grading Package C-Frame, LGP Fine Grading Ar XL AccuGrade ARO (Cab) 6VPAT LGP Foldable Fine Grading Package Fine Grading Ar LGP AccuGrade ARO (Cab) Dual Control Package Cab Control Dual, Cab Cover Console, Dual Control Tractor, Winch Ready Hydraulics, 4 Valve, 6VPAT Dual Control Package Canopy Control Dual, Canopy Tractor, Winch Ready Hydraulics, 4 Valve, 6VPAT SU Package Cab 6 SU Bulldozer Complete Hydraulics, 4 Valves SU Cover Console, Ripper

15

D6N Track-Type Tractor

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at www. cat. com © 2009 Caterpillar Inc. [. . . ]

CATERPILLAR D6N BROCHURE (3015 ko)

CATERPILLAR D6N BROCHURE (3015 ko)