User manual HONEYWELL TLE 0.5-4.5 INSTALLATION

Lastmanuals offers a socially driven service of sharing, storing and searching manuals related to use of hardware and software : user guide, owner's manual, quick start guide, technical datasheets... DON'T FORGET : ALWAYS READ THE USER GUIDE BEFORE BUYING !!!

If this document matches the user guide, instructions manual or user manual, feature sets, schematics you are looking for, download it now. Lastmanuals provides you a fast and easy access to the user manual HONEYWELL TLE 0.5-4.5. We hope that this HONEYWELL TLE 0.5-4.5 user guide will be useful to you.

Lastmanuals help download the user guide HONEYWELL TLE 0.5-4.5.

Manual abstract: user guide HONEYWELL TLE 0.5-4.5INSTALLATION

Detailed instructions for use are in the User's Guide.

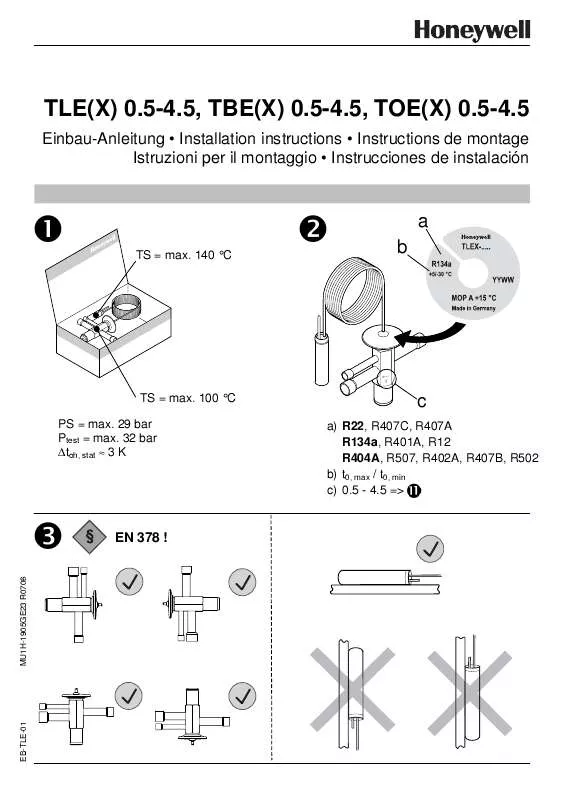

[. . . ] Obligatory for multiple injection by liquid distributors. · Combi adsorber charge as standard The same valve can be used for different refrigerants (see table on page 2) Controller charge is high sensitive and responsive thus lowest possible level of superheat can be achieved Charge is not sensitive to effects of temperature on the capillary tube and valve head damping characteristic results in stable control behaviour · Gas charge for deep freeze applications · Adjustable superheat setting · Warm thermal head provides best reliability TLE 0. 5-4. 5 0. 5-4. 5X · Solder connections · Extreme durable due to stainless steel head and stainless steel diaphragm welded using protective gas · Fixed orifice · Refrigerants: R134a, R401A, R12 R22, R407C, R407A, R422D R404A, R507A, R402A, R407B, R502 R410A R23, ISC 89, R508A, R508B Further refrigerants on request.

TLE 0. 5-4. 5 0. 5-4. 5

Application

Thermostatic expansion valves series TLE 0. 5-4. 5 0. 5-4. 5 and TLE 0. 5-4. 5 0. 5-4. 5X are used in plants with one or more refrigerant circuits, in particular for series systems such as heat pumps, refrigerated cabinets, deep freeze chests, freezers, fermentation interrupters, ice and cream machines, compact systems in refrigeration and air conditioning.

Materials

Body Thermal head Connection tubes brass stainless steel copper

Specification

Nominal capacity range 0. 99 to 17. 0 kW R22 (small orifice graduation for optimal control behaviour) see table on page 2 see table on page 2 see table on page 2 100 °C 140 °C approx. [. . . ] 3 K 1. 5 m 12 mm

Evaporating temperature range Maximum pressure PS Maximum test pressure PF Max. bulb temperature Static superheat Length of capillary tube Bulb diameter

Copyright © 2009 Honeywell GmbH · Subject to change without notice

EN0H-1905GE23 R0709

SERIES TLE 0. 5-4. 5 0. 5-4. 5

Thermal Charges and Temperature Ranges

1. Adsorber charge Refrigerant R134a, R401A, R12 R22, R407C, R407A, R422D R404A, R507A, R402A, R407B, R502 R410A Evaporation PS temperature range (bar(a)) +15 °C to -30 °C +15 °C to -45 °C ±0 °C to -50 °C 34 36 36 PF

(bar(a))

3. Gas charge Refrigerant Evaporation temperature range ISC 89 39. 6 39. 6 R23 R410A +15 °C to -20 °C 40 44. 0 R508A R508B -40 °C to -70 °C -55 °C to -70 °C -40 °C to -80 °C -55 °C to -80 °C +15 °C to -50 °C -40 °C to -70 °C -55 °C to -70 °C -40 °C to -90 °C -55 °C to -90 °C MOP PS

(bar(a))

PF

(bar(a))

37. 4

MOP -40 °C MOP -55 °C MOP -40 °C MOP -55 °C MOP -40 °C MOP -55 °C MOP -40 °C MOP -55 °C

29 29 29 29 29 29 29 29 29 29

31. 9 31. 9 31. 9 31. 9 44. 0 31. 9 31. 9 31. 9 31. 9 31. 9 31. 9

MOP +15 °C 40

Further refrigerants on request. Thermal systems with adsorber charge are completely insensitive to effects of temperature on the capillary tube and valve head. It reacts only according to the temperature of the bulb. Thus, Honeywell TLE 0. 5-4. 5 0. 5-4. 5 and TLE 0. 5-4. 5 0. 5-4. 5X valves with combi adsorber charge work absolutely reliable, even in icy condition or while defrosting using hot gas. · Constructive modifications at the valve are not allowed. Information for original equipment manufacturers: The valve series TLE 0. 5-4. 5 0. 5-4. 5 can be customised to the requirements of your series device in an optimum way. Contact us!

Superheat Adjustment

In general the Honeywell valves should be installed with the factory setting for the used refrigerant unaltered. At combi adsorber valves the label on the capillary tube indicates how to adjust the adjusting spindle (with arrow for direction), depending on the refrigerant used. This correction of the adjustment is essential to ensure that the control performance of the valve is correct. The refrigerant used must be marked on the label. This superheat adjustment is calibrated for lowest superheating and optimum evaporator utilisation. [. . . ] This superheat adjustment is calibrated for lowest superheating and optimum evaporator utilisation. However, should it be necessary to adjust the superheat, turn the adjusting spindle as follows: Turning clockwise Turning counterclockwise = = reduced refrigerant mass flow, increase of superheat increased refrigerant mass flow, decrease of superheat

One turn of adjusting spindle alters superheat setting by approx. [. . . ]

DISCLAIMER TO DOWNLOAD THE USER GUIDE HONEYWELL TLE 0.5-4.5 Lastmanuals offers a socially driven service of sharing, storing and searching manuals related to use of hardware and software : user guide, owner's manual, quick start guide, technical datasheets...manual HONEYWELL TLE 0.5-4.5