User manual HONEYWELL TMX

Lastmanuals offers a socially driven service of sharing, storing and searching manuals related to use of hardware and software : user guide, owner's manual, quick start guide, technical datasheets... DON'T FORGET : ALWAYS READ THE USER GUIDE BEFORE BUYING !!!

If this document matches the user guide, instructions manual or user manual, feature sets, schematics you are looking for, download it now. Lastmanuals provides you a fast and easy access to the user manual HONEYWELL TMX. We hope that this HONEYWELL TMX user guide will be useful to you.

Lastmanuals help download the user guide HONEYWELL TMX.

You may also download the following manuals related to this product:

Manual abstract: user guide HONEYWELL TMX

Detailed instructions for use are in the User's Guide.

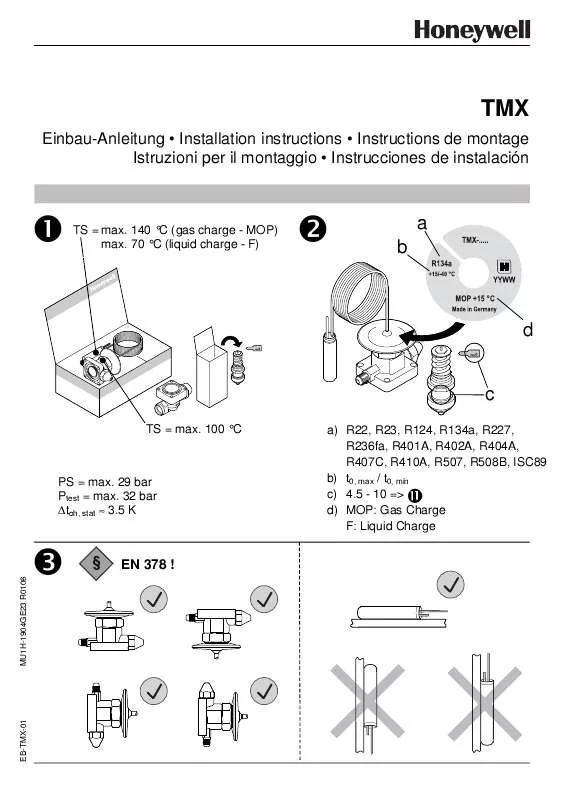

[. . . ] 3. 5 K 2m 16 mm Evaporating temperature range Maximum pressure PS Maximum test pressure PF Max. bulb temperature Static superheat Length of capillary tube Bulb diameter

Application

Thermostatic expansion valves series TMX are used in general refrigeration and for original equipment. [. . . ] Plants with one or more refrigerant circuits such as refrigerated cabinets, deep freezing plants, milk cooling units, water chillers, air conditioning systems, cold stores and heat pumps. For plants with single and multiple injections, with high or low flow resistance, for all kind of distributors.

Materials

Body Thermal head Base brass stainless steel brass

Copyright © 2009 Honeywell GmbH · Subject to change without notice

EN0H-1904GE23 R0709

SERIES TMX

Thermal Charges and Temperature Ranges

1. Gas charge with pressure limiting MOP Refri- Evaporation gerant temperature range Commercial refrigerants R22 +15 °C to -45 °C +10 °C to -45 °C ±0 °C to -45 °C -10 °C to -45 °C -18 °C to -45 °C R134a +25 °C to -40 °C +20 °C to -40 °C +15 °C to -40 °C +10 °C to -40 °C ±0 °C to -40 °C R401A +10 °C to -40 °C R404A +10 °C to -50 °C ±0 °C to -50 °C -10 °C to -50 °C -18 °C to -50 °C -30 °C to -50 °C R407C +15 °C to -30 °C +10 °C to -30 °C ±0 °C to -30 °C R410A +15 °C to -50 °C -10 °C to -50 °C -15 °C to -50 °C -20 °C to -50 °C R422D +15 °C to -45 °C -18 °C to -45 °C R507A +10 °C to -50 °C ±0 °C to -50 °C -18 °C to -50 °C MOP PS

(bar(a))

PF

(bar(a))

Refrigerant

Evaporation temperature range

MOP

PS

(bar(a))

PF

(bar(a))

MOP +15 °C MOP +10 °C MOP ±0 °C MOP -10 °C MOP -18 °C MOP +25 °C MOP +20 °C MOP +15 °C MOP +10 °C MOP ±0 °C MOP +10 °C MOP +10 °C MOP ±0 °C MOP -10 °C MOP -18 °C MOP -30 °C MOP +15 °C MOP +10 °C MOP ±0 °C MOP +15 °C MOP -10 °C MOP -15 °C MOP -20 °C MOP +15 °C MOP -18 °C MOP +10 °C MOP ±0 °C MOP -18 °C

36 36 29 29 29 34 34 34 34 29 34 36 36 34 34 29 36 36 29 40 29 29 29 36 29 36 36 34

39. 6 39. 6 31. 9 31. 9 31. 9 37. 4 37. 4 37. 4 37. 4 31. 9 37. 4 39. 6 39. 6 37. 4 37. 4 31. 9 39. 6 39. 6 31. 9 44. 0 31. 9 31. 9 31. 9 39. 6 31. 9 39. 6 39. 6 37. 4

Deep freeze refrigerants R23 -40 °C to -80 °C MOP -40 °C 29 31. 9 -55 °C to -80 °C MOP -55 °C 29 31. 9 R410A -40 °C to -70 °C MOP -40 °C 29 31. 9 R508B -55 °C to -100 °C MOP -55 °C 29 31. 9 Isceon 89 -40 °C to -70 °C MOP -40 °C 29 31. 9 Further refrigerants and MOP on request. MOP valves protect the compressor by limiting the increase of suction pressure. The MOP value should be chosen for the max. permissible suction pressure of the compressor or min. 5 K higher than the required evaporating temperature of the system. An overbow is recommended in order to prevent the ingress of oil into the equaliser line. · The bulb should preferably be positioned on the upper half of a horizontal suction line but never after a liquid trap. As a general rule, bulbs of expansion valves should be insulated to prevent them being affected by the ambient temperature. · Do not bend or squeeze the bulb when tightening the bulb clamp · Never quench the base with water after soldering, this may cause cracks and distort the sealing surfaces. · The screws fixing the valve body to the solder base must be tightened in diagonal sequence (torque 20 Nm). · Constructive modifications at the valve are not allowed.

Superheat Adjustment

In general the Honeywell valves should be installed with the factory setting for the used refrigerant unaltered. This superheat adjustment is calibrated for lowest superheating and optimum evaporator utilisation. [. . . ] This superheat adjustment is calibrated for lowest superheating and optimum evaporator utilisation. However, should it be necessary to adjust the superheat, turn the adjusting spindle as follows: Turning clockwise Turning counterclockwise = = reduced refrigerant mass flow, increase of superheat increased refrigerant mass flow, decrease of superheat

One turn of adjusting spindle alters superheat setting by approx. [. . . ]

DISCLAIMER TO DOWNLOAD THE USER GUIDE HONEYWELL TMX Lastmanuals offers a socially driven service of sharing, storing and searching manuals related to use of hardware and software : user guide, owner's manual, quick start guide, technical datasheets...manual HONEYWELL TMX

HONEYWELL TMX DATASHEET (293 ko)

HONEYWELL TMX DATASHEET (293 ko)