Detailed instructions for use are in the User's Guide.

[. . . ] INSTALLATION AND OPERATION MANUAL

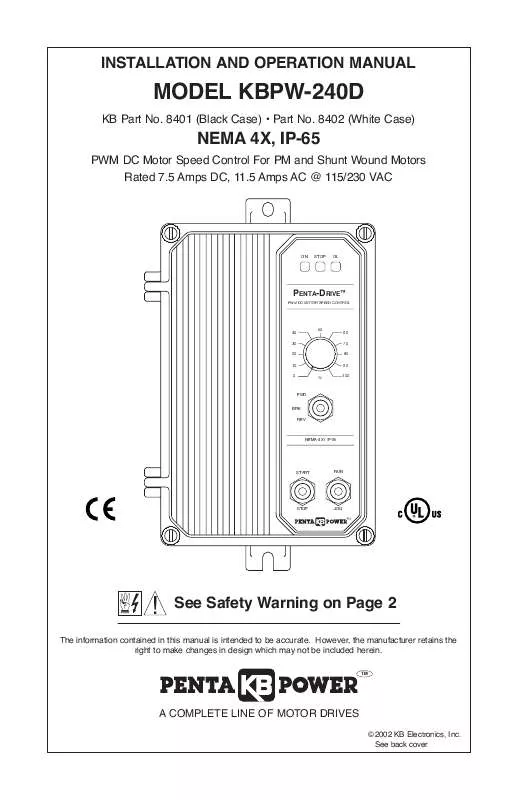

MODEL KBPW-240D

KB Part No. 8402 (White Case)

NEMA 4X, IP-65

PWM DC Motor Speed Control For PM and Shunt Wound Motors Rated 7. 5 Amps DC, 11. 5 Amps AC @ 115/230 VAC

ON

STOP

OL

PENTA-DRIVETM

PWM DC MOTOR SPEED CONTROL

40 30 20 10 0

50

60 70 80 90

%

100

FWD BRK REV

NEMA-4X / IP-65

START

RUN

STOP

JOG

TM

!

See Safety Warning on Page 2

The information contained in this manual is intended to be accurate. However, the manufacturer retains the right to make changes in design which may not be included herein.

TM

A COMPLETE LINE OF MOTOR DRIVES

© 2002 KB Electronics, Inc. See back cover

TABLE OF CONTENTS Section i. [. . . ] Jumper J4 must be in "7V" position for 7 Volt per 1000 RPM tach-generators or "50V" position for 50 Volt per 1000 RPM tach-generators. Note: When using a tach-generator, the IR trimpot should be set fully counterclockwise. IV.

SETTING SELECTABLE JUMPERS The KBPW-240D has customer selectable jumpers which must be set before the control can be used. See Figure 1, on page 4 for location of jumpers. Motor Voltage Selection (J1) Jumper J1 is factory set to "90V" position for 90 Volt SCR rated motors (or 130 Volt PWM rated motors). For 180 Volt SCR rated motors (or 220 Volt PWM rated motors), set jumper J1 to "180V" position. Note: If jumper J1 is set to "T" position, a tach-generator must be wired to TB3. If a tach-generator is not used, jumper J1 must be in either "90V" or "180V" position. If jumper J1 is in "T" position and a tach-generator is not used, the motor will accelerate to full speed and the main speed potentiometer will not control speed. Motor Current Selection (J2) Jumper J2 is factory set to "7. 5A" position for 7. 5 Amp motors. For motors of lower amperage, set Jumper J2 to the corresponding position for the motor being used. Note: For low (L) motor current settings (0. 8A, 0. 5A, 0. 4A, 0. 3A, and 0. 2A), it is necessary to remove resistor R35. Cut the leads at the locations shown in Figure 16.

FIGURE 14 MOTOR VOLTAGE SELECTION

J1 Set for 90 Volt Motors (Factory Setting) J1 Set for 180 Volt Motors

J1 T 90V 180V T

J1 180V 90V

FIGURE 15 MOTOR CURRENT SELECTION

J2 Set for 7. 5 Amp Motor (Factory Setting) High Scale Current Range (Amps DC) 7. 5 5. 0 3. 5 2. 5 1. 7 Low Scale Current Range* (Amps DC) 0. 8 0. 5 0. 4 0. 3 0. 2

*Note: For low (L) motor current range settings (0. 8A, 0. 5A, 0. 4A, 0. 3A and 0. 2A), it is necessary to remove resistor R35 by cutting it out of the circuit as shown in figure 16 on page 10.

FIGURE 16 REMOVING RESISTOR R35

TO REMOVE RESISTOR R35 CUT THE LEADS HERE

R35

BLU BLU WHT WHT

J7A J7B

D6

ORG RED WHT BLK L1A L1B

J6A J6B

L2A

L2B

Q4

D20

A1B

A1A

A2B

A2A

CON2 TB2

TB1

Q5

F1 F2

WARNING!Disconnect AC line before cutting out resistor R35. Use an insulated cutter and wear safety glasses.

A1

A2

L1

L2

!

TABLE 5 SETTING MOTOR CURRENT (SCR & PWM Motor Horsepower Ratings)

J2 Setting (Amps DC) 7. 5 5. 0 3. 5 2. 5 1. 7 0. 8* 0. 5* 0. 4* 0. 3* 0. 2* SCR Rated Motor Horsepower HP, (kW) 90 Volts DC Motors 3/4, (0. 5) 1/2, (0. 37) 1/3, (0. 25) 1/4, (0. 18) 1/6, (0. 1) 1/12, (0. 06) 1/20, (0. 04) 1/25, (0. 03) 1/30, (0. 02) 1/50, (0. 01) 180 Volts DC Motors 11/2, (1) 1, (0. 75) 3/4, (0. 5) 1/2, (0. 37) 1/3, (0. 25) 1/6, (0. 1) 1/10, (0. 08) 1/12, (0. 06) 1/15, (0. 05) 1/25, (0. 03) PWM Rated Motor Horsepower HP, (kW) 130 Volts DC Motors 1, (0. 75) 3/4, (0. 5) 1/2, (0. 37) 1/3, (0. 25) 1/4, (0. 18) 1/8, (0. 09) 1/15, (0. 05) 1/20, (0. 04) 1/25, (0. 03) 1/30, (0. 02) 220Volts DC Motors 2, (1. 5) 11/2, (1) 1, (0. 75) 3/4, (0. 5) 1/2, (0. 37) 1/4, (0. 18) 1/6, (0. 1) 1/8, (0. 09) 1/10, (0. 08) 1/20, (0. 04)

*Note: For low (L) motor current range settings (0. 8A, 0. 5A, 0. 4A, 0. 3A and 0. 2A), it is necessary to remove resistor R35 as shown in figure 16.

10

C. Timed and Non-Timed Current Limit Selection (J3) Jumper J3 is factory set to "TCL" position for timed current limiting operation. For non-timed current limiting operation, set jumper J3 to "NTCL" position. TCL (Timed Current Limit) When Jumper J3 is in the "TCL" position, the control will go into "STOP" after it is in overload for a predetermined amount of time (set by the TCL trimpot).

FIGURE 17 CURRENT LIMIT MODE SELECTION

J3 Set for TCL Mode (Timed Current Limit) (Factory Setting) J3 Set for NTCL Mode (Non-Timed Current Limit)

J3

TCL NTCL

J3

TCL NTCL

Resetting the Control After TCL To reset the control after it has gone into TCL, momentarily set the Start/Stop switch to "START" position or disconnect and reconnect the AC line. If an On/Off AC Line Switch is installed, set it to "OFF" position and then back to "ON" position. If the Start switch is jumpered (START and COM terminals connected), the control must be restarted by disconnecting and reconnecting the AC line. NTCL (Non-Timed Current Limit) When jumper J3 is set to "NTCL" position, the control will not go into "STOP" after it is in overload. Note: TCL trimpot will have no affect when jumper J3 is in "NTCL" position. [. . . ] Mounts on the enclosure cover and is supplied with a switch seal to maintain watertight integrity. Run-Stop-Jog Switch (P/N 9340) Selects speed setting from either main potentiometer or JOG trimpot. Mounts on the enclosure cover and is supplied with a switch seal to maintain watertight integrity. Signal Isolator KBSI-240D (P/N 9431) Provides isolation from non-isolated signal sources. [. . . ]