Detailed instructions for use are in the User's Guide.

[. . . ] )

ME77

GB F D NL S DK N FIN E P I H CZ TR

INSTRUCTIONS INSTRUCTIONS HINWEISE INSTRUCTIES INSTRUKTIONER INSTRUKTION ANVISNING OHJEET INSTRUCCIONES INSTRUES ISTRUZIONI LERS POKYNY KILAVUZ

page 8 page 12 Seite 17 bladz. 54 oldal 59 strana 64 sayfa 68

PL RU UA GR RO BG SK HR SRB SLO EST LV LT

INSTRUKCJA O INSTRUCIUNI

strona 73 78 84 89 pagina 95

KA3A

POKYNY UPUTE UPUTSTVA NAVODILA INSTRUKCIJA INSTRUKCIJA

100

strana 106 stranica 110 stranica 115 stran 119 lappuse 128 puslapis 133

KASUTUSJUHEND leheklg 123

www. skileurope. com

SKIL Europe BV - Konijnenberg 60 4825 BD Breda - The Netherlands 11/07 2610397944

1

5840

800 W 3, 6 kg

90

45

140 mm MAX.

122 mm MIN.

40 mm

30 mm

4300

20 mm

20 mm

2

3

A

E

D C B

F

G

2

4

K

H J

3 mm

5

L M

J

3

6

N

40 mm

40 mm

0

90

4

7

Q T P

S

R

F

E

8

5

9

V

U

0

E

N F

6

!

@

ACCESSORIES

SKIL Nr.

18x

140 mm

20 mm

1, 4 / 2, 4

2610396609

2610387402

2610397945

7

GB

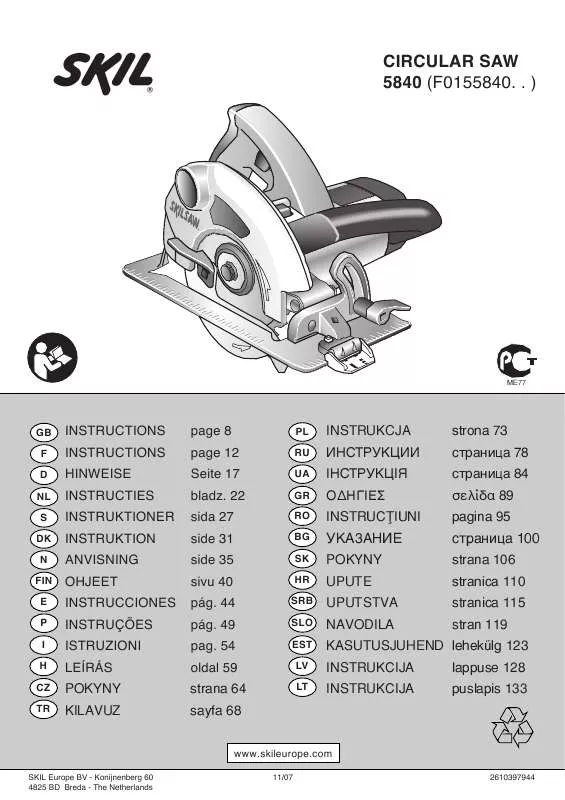

Circular saw INTRODUCTION

5840

This tool is intended for lengthways and crossways cutting of wood with straight cuts as well as angle cuts to 45; with the appropriate saw blades also non-ferrous metals, light building materials and plastics can be cut Read and save this instruction manual 2

TECHNICAL SPECIFICATIONS 1 SAFETY

GENERAL SAFETY INSTRUCTIONS WARNING!Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury. [. . . ] This will ensure that the safety of the power tool is maintained. SAFETY INSTRUCTIONS FOR CIRCULAR SAWS DANGER Keep hands away from cutting area and the blade; keep your second hand on front handle (if both hands are holding the saw, they can not be cut by the blade) Do not reach underneath the workpiece (the guard cannot protect you from the blade below the workpiece) Adjust the cutting depth to the thickness of the workpiece (less than a full tooth of the blade teeth should be visible below the workpiece) Never hold piece being cut in your hands or across your leg (it is important to support the work properly to minimise body exposure, blade binding, or loss of control) Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord (contact with a "live" wire will also make exposed metal parts of the tool "live" and shock the operator) When ripping always use a rip fence or straight edge guide (this improves the accuracy of cut and reduces the chance for blade binding) Always use blades with correct size and shape of arbor holes (diamond or round) (blades that do not match the mounting hardware of the saw will run eccentrically, causing loss of control) Never use damaged or incorrect blade washers or bolts (the blade washers and bolt were specially designed for your saw, for optimum performance and safety of operation) KICKBACK - CAUSES Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an uncontrolled saw to lift up and out of the workpiece toward the operator When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the motor reaction drives the unit rapidly back toward the operator If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the kerf and jump back towards operator

KICKBACK - OPERATOR PREVENTION Kickback is the result of tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below Maintain a firm grip with both hands on the saw and position your arms to resist kickback forces; position your body to either side of the blade, but not in line with the blade (kickback could cause the saw to jump backwards, but kickback forces can be controlled by the operator, if proper precautions are taken) When blade is binding, or when interrupting a cut for any reason, release the trigger and hold the saw motionless in the material until the blade comes to a complete stop; never attempt to remove the saw from the work or pull the saw backwards while the blade is in motion or kickback may occur (investigate and take corrective actions to eliminate the cause of blade binding; avoid cutting nails or screws) When restarting a saw in the workpiece, centre the saw blade in the kerf and check that saw teeth are not engaged into the material (if saw blade is binding, it may walk up or kickback from the workpiece as the saw is restarted) Support large panels to minimise the risk of blade pinching and kickback (large panels tend to sag under their own weight; supports must be placed under the panel on both sides, near the line of cut and near the edge of the panel) Do not use a dull or damaged blade (unsharpened or improperly set blades produce narrow kerf causing excessive friction, blade binding and kickback) Blade depth and bevel adjusting locking levers must be tight and secure before making cut (if blade adjustment shifts while cutting, it may cause binding and kickback) Use extra caution when making a plunge cut into existing walls or other blind areas (the protruding blade may cut objects that can cause kickback) WARNING Check lower guard for proper closing before each use Do not operate the saw if lower guard does not move freely and close instantly Never clamp or tie the lower guard into the open position If saw is accidentally dropped, lower guard may be bent; raise the lower guard with the retracting handle and make sure it moves freely and does not touch the blade or any other part, in all angles and depths of cut Check the operation of the lower guard spring; if the guard and the spring are not operating properly, they must be serviced before use (lower guard may operate sluggishly due to damaged parts, gummy deposits, or a build-up of debris)

9

Lower guard should be retracted manually only for special cuts such as plunge cuts and compound cuts; raise lower guard by retracting handle and as soon as blade enters the material, the lower guard must be released (for all other sawing, the lower guard should operate automatically) Always observe that the lower guard is covering the blade before placing saw down on bench or floor (an unprotected, coasting blade will cause the saw to walk backwards, cutting whatever is in its path; be aware of the time it takes for the blade to stop after switch is released) GENERAL Avoid damage that can be caused by screws, nails and other elements in your workpiece; remove them before you start working When you put away the tool, switch off the motor and ensure that all moving parts have come to a complete standstill Use completely unrolled and safe extension cords with a capacity of 16 Amps (U. K. make sure that clamping surfaces G of flanges are perfectly clean and face the blade - push spindle-lock button A and hold it while you tighten blade bolt with blade wrench 1/8 turn past finger tight (ensures slippage of saw blade when it encounters excessive resistance thus reducing motor overload and saw kickback) - release spindle-lock button A Adjusting cutting depth (0-40 mm) 4 - for an optimal quality cut the saw blade should not extend more than 3 mm below the workpiece - loosen knob H - raise/lower foot J until desired cutting depth is set on scale using indicator K - tighten knob H

10

Adjusting cutting angle (0-45) 5 - loosen knob L - tilt tool until desired cutting angle is set on scale using indicator M - tighten knob L !when bevel cutting, cutting depth does not correspond with value on cutting depth scale 90 Cutting angle check 5 - adjust and tighten foot J to maximum cutting depth 4 - adjust and tighten cutting angle to 0 - check for 90 angle between the blade and bottom of foot with a square Adjustable saw line visor N 6a - for guiding tool along desired line of cut marked on the workpiece - for a straight 0 cut or a 45 bevel cut use the indicator line concerned !the wide part of the foot should rest on the supported part of the workpiece - can be adjusted to allow you to choose whether waste material is on inner or outer side of blade 6b !cutting width is determined by width of blade teeth and not bywidth of blade body !always make trial cuts first to verify actual line of cut Dust suction - connect vacuum cleaner to extension P 7 !never let the vacuum cleaner hose interfere with the lower guard or the cutting operation - one may also use a dust bag (SKIL accessory 2610387402) !do not use dustbag/vacuum cleaner when cutting metal Operating the tool 7 - connect plug to power source - always hold handle Q firmly with one hand and handle R firmly with the other hand - place tool with front end of foot flat on workpiece !ensure that the saw teeth are not engaged into the workpiece - switch on tool by first pressing knob S (= safety switch which cannot be locked) and then pulling trigger T !the tool should run at full speed before the blade enters into the workpiece - lower guard E opens automatically when saw blade enters the workpiece (open lower guard manually by using lever F only for special cuts such as plunge cuts) - do not force the tool; apply light and continuous pressure - after completing the cut switch off tool by releasing trigger T !ensure that the blade has come to a complete standstill, before you lift the tool from the workpiece

APPLICATION ADVICE

Always face the good side of the workpiece down to ensure minimum splintering Only use sharp saw blades of the correct type 8 - quality of cut improves by the number of teeth - carbide tipped blades stay sharp up to 30 times longer than ordinary blades Rip fence U 9 (available as SKIL accessory 2610397945) - for making exact cuts along a workpiece edge - can be inserted in either side of foot Adjusting rip fence - loosen knob V - adjust to desired cutting width by using rip fence scale (use saw line visor N as 0-reference) - tighten knob V Plunge cutting 0 - set desired cutting depth - tilt tool forward with saw line visor N lined up with desired line of cut marked on the workpiece - open lower guard E with lever F - just before blade enters workpiece, switch on tool and gradually lower back end of tool using front end of foot as hinge-point - gradually move tool downward as well as forward - as soon as blade enters the material, release lever F !never pull tool backwards Cutting large panels !- support panel close to the cut either on floor, table or workbench !set cutting depth so that you cut through panel and not through support - in case rip fence does not allow desired width of cut, clamp or nail straight piece of wood to workpiece as a guide, and use the right side of the foot against this guide For more tips see www. skileurope. com Vibration level The vibration emission level stated at the back of this instruction manual has been measured in accordance with a standardised test given in EN 60745; it may be used to compare one tool with another and as a preliminary assessment of exposure to vibration when using the tool for the applications mentioned - using the tool for different applications, or with different or poorly maintainted accessories, may significantly increase the exposure level - the times when the tool is switched off or when it is running but not actually doing the job, may significantly reduce the exposure level !protect yourself against the effects of vibration by maintaining the tool and its accessories, keeping your hands warm, and organizing your work patterns

11

139

140

GB

CE DECLARATION OF CONFORMITY We declare under our sole responsibility that this product is in conformity with the following standards or standardized documents: EN 60 745, EN 55 014, in accordance with the provisions of the directives 2006/95/EC, 2004/108/EC, 98/37/EC (until Dec. NOISE/VIBRATION Measured in accordance with EN 60 745 the sound pressure level of this tool is 93 dB(A) and the sound power level 104 dB(A) (standard deviation: 3 dB), and the vibration 1. 7 m/s2 (hand-arm method; uncertainty K = 1. 5 m/s2). Technical file at: SKIL Europe BV (PT-SEU/PJE), 4825 BD Breda, NL.

F

CE DCLARATION DE CONFORMIT Nous dclarons sous notre propre responsabilit que ce produit est en conformit avec les normes ou documents normaliss suivants: EN 60 745, EN 55 014, conforme aux rglementations 2006/95/CE, 2004/108/CE, 98/37/CE (jusqu'au 28. 12. 2009), 2006/42/CE ( partir du 29. 12. 2009). BRUIT/VIBRATION Mesur selon EN 60 745 le niveau de la pression sonore de cet outil est 93 dB(A) et le niveau de la puissance sonore 104 dB(A) (dviation standard: 3 dB), et la vibration 1, 7 m/s2 (mthode main-bras; incertitude K = 1, 5 m/s2). Dossier technique auprs de: SKIL Europe BV (PT-SEU/PJE), 4825 BD Breda, NL.

D

CE KONFORMITTSERKLRUNG Wir erklren in alleiniger Verantwortung, da dieses Produkt mit den folgenden Normen oder normativen Dokumenten bereinstimmt: EN 60 745, EN 55 014, gem den Bestimmungen der Richtlinien 2006/95/EG, 2004/108/EG, 98/37/EG (bis 28. 12. 2009), 2006/42/EG (ab 29. 12. 2009). GERUSCH/VIBRATION Gemessen gem EN 60 745 betrgt der Schalldruckpegel dieses Gertes 93 dB(A) und der Schalleistungspegel 104 dB(A) (Standard- abweichung: 3 dB), und die Vibration 1, 7 m/s2 (Hand-Arm Methode; unsicherheit K = 1, 5 m/s2). Technische Unterlagen bei: SKIL Europe BV (PT-SEU/PJE), 4825 BD Breda, NL.

NL

CE CONFORMITEITSVERKLARING Wij verklaren, dat dit product voldoet aan de volgende normen of normatieve documenten: EN 60 745, EN 55 014, overeenkomstig de bepalingen van de richtlijnen 2006/95/EG, 2004/108/EG, 98/37/EG (tot 28-12-2009), 2006/42/EG (vanaf 29-12-2009). [. . . ] Y / Y EN 60 745 93 dB(A) o 104 dB(A) ( : 3 dB), 1, 7 m/s2 ( / - K = 1, 5 m/s2). : SKIL Europe BV (PT-SEU/PJE), 4825 BD Breda, NL.

07

SKIL Europe BV A. Kloot

142

RO

DECLARAIE DE CONFORMITATE CE Declarm pe proprie rspundere c acest product este conform cu urmtoarele standarde sau documente standardizate: EN 60 745, EN 55 014, n conformitate cu regulile 2006/95/CE, 2004/108/CE, 98/37/CE (pn la 28. 12. 2009), 2006/42/CE (ncepnd cu 29. 12. 2009). ZGOMOT/VIBRAII Msurat n conformitate cu EN 60 745 nivelul de presiune a sunetului generat de acest instrument este de 93 dB(A) iar nivelul de putere a sunetului 104 dB(A) (abaterea standard: 3 dB), iar nivelul vibraiilor 1, 7 m/s2 (metoda mn - bra; incertitudine K = 1, 5 m/s2). [. . . ]