Detailed instructions for use are in the User's Guide.

[. . . ] See pages 4 and 5.

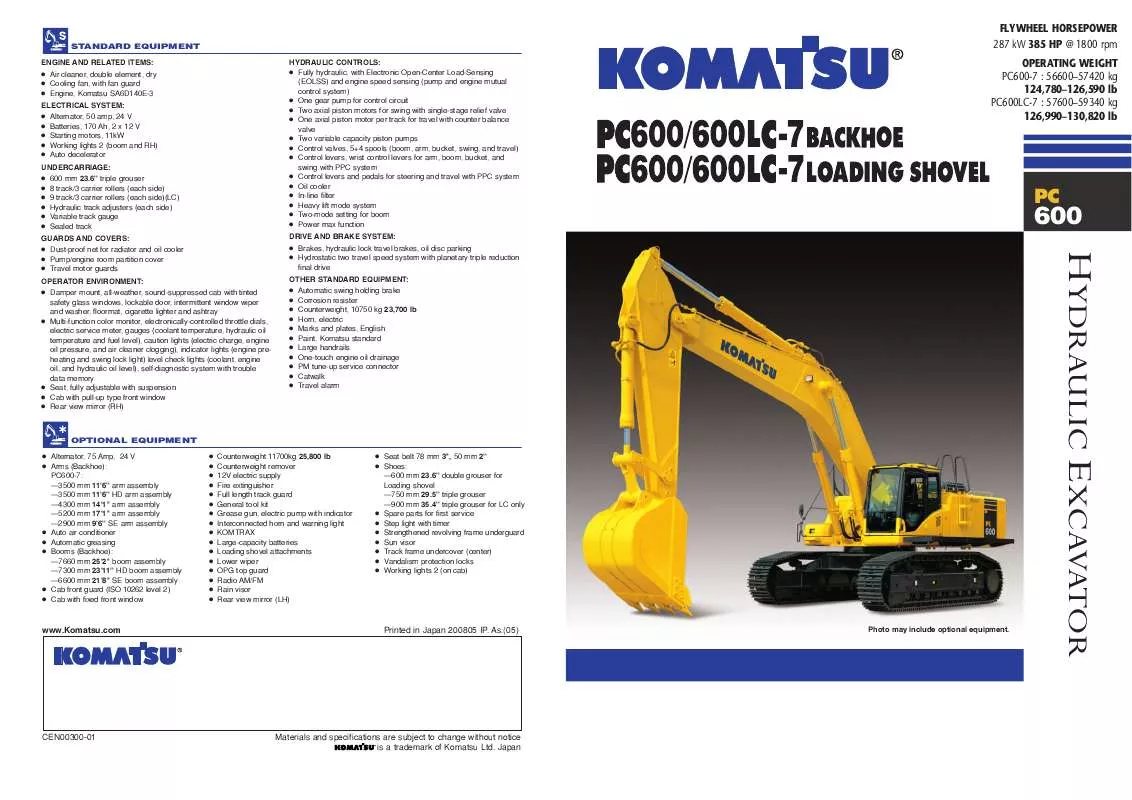

Photo may include optional equipment.

Excellent Reliability and Durability Strengthened boom and arm have large

Reinforced buckets are highly resistant

against wear and impacts. (optional)

Protected hydraulic circuit

cross-sections and reliable welding for maximum strength and reliability. (optional)

The cool-running hydraulic system is protected with the most extensive filtration system available, including a high pressure in-line filter for each main pump.

Advanced monitor features Large handrail, step and catwalk

provide easy access to the engine and hydraulic equipment. Machine condition can be checked with Equipment Management Monitoring System (EMMS). [. . . ] It is highly resistant against wear and impact and demonstrates high performance and reliability. Combined with the saddling type side shroud and the corner teeth, the life of the bucket has been greatly improved.

Lip shroud Corner tooth Bottom plate made of duplex wear plates Exclusive adaptor for the corner tooth Side panel reinforcement plate Side shroud (2 pieces per each side)

MAINTENANCE MAINTENANCE FEATURES FEATURES

Easy Maintenance

Komatsu designed the PC600-7 for easy service access.

Wide Catwalk

Wide walkway for maintenance is provided around the engine and hydraulic components, allowing easy access to inspection and maintenance points.

Footing Over Engine

Since a step is being installed to a section above the engine, daily inspections of the engine and its neighborhood can be conducted easily. Also, a protection cover is being adopted to prevent direct touch of hands to the high temperature sections such as the turbocharger.

Motorized Grease Gun Equipped with Hose Reel (optional)

Greasing is made easy with the electric motorized grease gun and indicator.

Strengthened Boom and Arm (optional)

Thanks to the large cross-sectional structure employing a high tensile strength steel with a thick plate, partition wall, etc. , the boom and arm exhibit excellent durability and are highly resistant to bends and twists.

High-pressure In-Line Filtration

The PC600-7 has the most extensive filtration system available, providing in-line filters as standard equipment. An in-line filter in the outlet port of each main hydraulic pump reduces failures caused by contamination.

Sturdy Undercarriage

The undercarriage is strengthened to provide excellent reliability and durability when working on rocky ground or blasted rock.

Indicator

Grease gun

Reduced Maintenance Costs

Hydraulic oil filter replacement is extended

Partition wall

KOMTRAX® System (optional)

The KOMTRAX system monitors machine condition, operating status, operating location, etc. , and provides timely notification of any machine problems. Since data is transmitted via satellite communication system, secure data communication is possible from any operating site including a quarry or a mine, further improving machine reliability. (There are some countries where this feature is not in service. Please consult Komatsu dis-

from 500 to 1000 hours.

Rock protectors

Wide width arm Arm dent preventive plate Large cross-sectional structure boom

Metal Guard Rings

Metal guard rings protect all the hydraulic cylinders and improve reliability.

Sturdy guards shield the travel motors and piping against damage from rocks. (Rock protectors are optional. )

O-Ring Face Seal

The hydraulic hose seal method has been changed from a conventional taper seal to an O-ring seal. Cab with fixed front window (optional) Internal air pressure : 10 mm Aq 0. 39" in Aq

(

)

Rigid and Safe Operator's Cab OPG top guard (optional) Single sheet fixed glass (optional) See-through skylight equipped with a sun shade (optional) Additional head lamp (optional) Lower wiper (optional) Horn interconnected with warning light (optional)

Engine/pump room partition

Automatic Air Conditioner (Optional)

A 6, 900 kcal air conditioner is utilized. The bi-level control function keeps the operator's head and feet cool and warm respectively. This improved air flow function keeps the inside of the cab comfortable throughout the year.

Engine/pump room partition prevents oil from spraying on the engine if a hydraulic hose should burst. Step light with timer (optional) provides light for about one minute to allow the operator to get off the machine safely. Large handrails and wide catwalk are provided around revolving frame for easier and safer access to engine and hydraulic components.

8

Photo may include optional equipment.

9

PC600-7

SPECIFICATIONS SPECIFICATIONS & EQUIPMENTIP & EQUIPMENTIPENGINE Model . 4-cycle, water-cooled, direct injection Aspiration . Turbocharged and aftercooled Number of cylinders . 287 kW 385 HP @ 1800 rpm (SAE J1349) Governor . All-speed, electronic SWING SYSTEM Driven method . Planetary gear Swing circle lubrication . 8. 3 rpm

A B C D E F G H

HYDRAULIC EXCAVATOR

DIMENSIONS

Boom Arm Overall length Overall height (to top of boom) 7660 mm 3500 mm 12810 mm 4300 mm 25'2" 11'6" 42'0" 14'1" 7660 mm 4300 mm 12730 mm 4655 mm 25'2" 14'1" 41'9" 15'3" 7660 mm 5200 mm 12435 mm 5235 mm 25'2" 17'1" 40'10" 17'2" 7300 mm 3500 mm 12440 mm 4280 mm

A G, R Q

23'11" 11'6" 40'10" 14'1"

6600 mm 2900 mm 11830 mm 4600 mm

21'8" 9'6" 38'10" 15'1"

Overall width Overall height (to top of cab) Ground clearance, counterweight Ground clearance (minimum) Tail swing radius Track length on ground Track length Track gauge Track gauge when expanded Width of crawler Width of crawler when expanded Shoe width Grouser height Machine cab height Machine cab width Distance, swing center to rear end

PC600-7 3900 mm 12'10" 3290 mm 1365 mm 780 mm 3800 mm 4250 mm 5340 mm 2590 mm 3300 mm 3190 mm 3900 mm 600 mm 37 mm 3070 mm 3195 mm 3675 mm 10'10" 4'6" 2'7" 12'6" 13'11" 17'6" 8'6" 10'10" 10'6" 12'10" 23. 6" 1. 5" 10'1" 10'6" 12'1"

PC600LC-7 3900 mm 12'10" 3290 mm 1365 mm 780 mm 3800 mm 4600 mm 5690 mm 2590 mm 3300 mm 3190 mm 3900 mm 600 mm 37 mm 3070 mm 3195 mm 3675 mm 10'10" 4'6" 2'7" 12'6" 15'1" 18'8" 8'6" 10'10" 10'6" 12'10" 23. 6" 1. 5" 10'1" 10'6" 12'1"

B

P E H I O

D F N J, K C, L, M

UNDERCARRIAGE Center frame . 9 each side (PC600LC-7) COOLANT AND LUBRICANT CAPACITY

(REFILLING)

I J K L M N O P Q R

HYDRAULIC SYSTEM Type . Open-center load-sensing system Number of selectable working modes . Variable-capacity piston pumps Pumps for. [. . . ] PC600-7 Operating Ground Weight Pressure 108 kPa 61100 kg 1. 10 kgf/cm2 134, 700 lb 15. 6 psi PC600LC-7 Operating Ground Weight Pressure 103 kPa 62200 kg 1. 05 kgf/cm2 137, 130 lb 14. 9 psi

Shoes

Double grouser

600 mm 23. 6"

10

11

PC600-7

HYDRAULIC EXCAVATOR

BACKHOE BUCKET AND ARM COMBINATION

BUCKET CAPACITY (HEAPED) SAE, PCSA m3 yd3 use with 7. 66m 25'2" boom 2. 0 2. 3 2. 7 2. 8 3. 1 2. 62 3. 01 3. 53 3. 66 4. 05 1. 8 2. 1 2. 4 2. 5 2. 8 2. 35 2. 75 3. 14 3. 27 3. 66 1430 1580 1780 1870 2000 56. 3" 62. 2" 70. 1" 73. 6" 78. 7" 1250 1400 1600 1870 2000 49. 2" 55. 1" 63. 0" 73. 6" 78. 6" 2200 2382 2505 2981 3100 4, 850 5, 250 5, 220 6, 570 6, 830 2. 9 9'6" SE arm CECE m3 yd3 WIDTH With Side shrouds, Side cutters mm in Without Side shrouds, Side cutters mm in WEIGHT (with side cutters) kg lb 3. 5 11'6" ARM LENGTH m ft in 4. 3 14'1" 5. 2 17'1"

B C

LIFTING CAPACITY

A

PC600-7

A: B: C: Cf: Cs: : Reach from swing center Bucket hook height Lifting capacity Rating over front Rating over side Rating at maximum reach

unit: kg lb 3. 0m 10' Cf Cs

-- 3. 5 11'6" HD arm

-- --

use with 7. 3m 23'11" HD boom

use with 6. 6m 21'8" SE boom

These charts are based on over-side stability with fully loaded bucket at maximum reach. : General purpose use, density up to 1. 8 t/m3 3, 000 lb/yd3 : General purpose use, density up to 1. 5 t/m3 2, 500 lb/yd3 -- : Not useable : Bucket lip width : Installed to LC crawler

LOADING SHOVEL DIMENSIONS

8815 28'11" 3675 12'1" 5140 16'10" R=3800 12'6" 3195 10'6"

Boom : 7. 66m 25'2", Arm : 3. 5m 11'6", Bucket : 2. 7m3 3. 53cu. yd, Shoes : 600mm 23. 6" triple, Heavy-lifting: "OFF" A MAX 9. 1m 30' 7. 6m 25' 6. 1m 20' B Cf Cs Cf Cs Cf Cs Cf Cs 9. 1m *8000 *8000 30' *17, 600 *17, 600 7. 6m *7800 *7800 *9250 9050 25' *17, 200 *17, 200 *20, 400 19, 900 6. 1m *7900 7250 *10150 8950 *11450 *11450 20' *17, 400 16, 000 *22, 400 19, 700 *25, 300 *25, 300 4. 6m *8300 6450 *10800 8650 *12700 12100 *15950 *15950 15' *18, 300 14, 200 *23, 800 19, 000 *28, 000 26, 600 *35, 100 *35, 100 3. 0m 8150 6050 11000 8300 *14000 11400 *18200 16350 10' 18, 000 13, 300 24, 200 18, 300 *30, 800 25, 100 *40, 100 36, 100 1. 5m 8000 5900 10650 7950 14400 10800 *19650 15350 5' 17, 700 13, 000 23, 400 17, 500 31, 800 23, 800 *43, 300 33, 800 0m 8200 6050 10350 7700 13500 9950 *20100 14800 0' 18, 100 13, 300 22, 900 17, 000 29, 800 21, 900 *44, 300 32, 700 -1. 5m 8850 6550 10250 7600 13250 9700 *19550 14650 -5' 19, 500 14, 400 22, 600 16, 700 29, 200 21, 400 *43, 200 32, 300 -3. 0m 10150 7550 10350 7650 13500 9950 *18100 14800 -10' 22, 400 16, 600 22, 800 16, 900 29, 800 22, 000 *39, 900 32, 600 -4. 6m *10400 9550 *11750 10550 *15400 15200 -15' *22, 900 21, 000 *25, 900 23, 300 *34, 000 33, 500 -6. 1m *9250 *9250 *10400 *10400 -20' *20, 500 *20, 500 *22, 900 *22, 900 Boom : 7. 66m 25'2", Arm : 3. 5m 11'6", Bucket : 2. 7m3 3. 53cu. yd, Shoes : 600mm 23. 6" triple, Heavy-lifting: "ON" A MAX 9. 1m 30' 7. 6m 25' 6. 1m 20' B Cf Cs Cf Cs Cf Cs Cf Cs 9. 1m *8850 *8850 30' *19, 500 *19, 500 7. 6m *8600 *8600 *10200 9050 25' *19, 000 *19, 000 *22, 500 19, 900 6. 1m *8750 7250 *11350 8950 *12750 12700 20' *19, 300 16, 000 *25, 100 19, 700 *28, 100 28, 000 4. 6m 8650 6450 11350 8650 *14150 12100 *17650 *17650 15' 19, 100 14, 200 25, 000 19, 000 *31, 200 26, 600 *38, 900 *38, 900 3. 0m 8150 6050 11000 8300 15050 11400 *20150 16350 10' 18, 000 13, 300 24, 200 18, 300 33, 200 25, 100 *44, 500 36, 100 1. 5m 8000 5900 10650 7950 14400 10800 20750 15350 5' 17, 700 13, 000 23, 400 17, 500 31, 800 23, 800 45, 800 33, 800 0m 8200 6050 10350 7700 13500 9950 20200 14800 0' 18, 100 13, 300 22, 900 17, 000 29, 800 21, 900 44, 500 32, 700 -1. 5m 8850 6550 10250 7600 13250 9700 20000 14650 -5' 19, 500 14, 400 22, 600 16, 700 29, 200 21, 400 44, 100 32, 300 -3. 0m 10150 7550 10350 7650 13500 9950 20150 14800 -10' 22, 400 16, 600 22, 800 16, 900 29, 800 22, 000 44, 400 32, 600 -4. 6m *11750 9550 *13250 10550 *17250 15200 *25, 900 21, 000 *29, 200 23, 300 *38, 000 33, 500 -15' -6. 1m *10550 *10550 *11800 *11800 -20' *23, 300 *23, 300 *26, 000 *26, 000 Boom : 7. 3m 23'11", Arm : 3. 5m 11'6", Bucket : 2. 8m3 3. 66cu. yd, Shoes : 600mm 23. 6", Heavy-lifting: "OFF" A MAX 9. 1m 30' 7. 6m 25' 6. 1m 20' B Cf Cs Cf Cs Cf Cs Cf Cs 9. 1m *7550 *7550 *8400 *8400 30' *16, 600 *16, 600 *18, 500 *18, 500 7. 6m *7300 *7300 *10500 *10500 25' *16, 200 *16, 200 *23, 100 *23, 100 6. 1m *7450 *7450 *10100 8650 *11300 *11300 20' *16, 400 *16, 400 *22, 300 19, 100 *24, 900 *24, 900 4. 6m *7850 6800 *10700 8450 *12500 12050 *15550 *15550 15' *17, 300 15, 000 *23, 600 18, 600 *27, 600 26, 500 *34, 800 *34, 300 3. 0m *8550 6300 10850 8150 *13800 11400 *17200 15900 10' *18, 800 18, 900 24, 000 17, 900 *30, 400 25, 100 *38, 000 35, 100 1. 5m 8450 6200 10550 7850 14500 10850 *19450 15600 5' 18, 800 13, 600 23, 300 17, 300 32, 000 23, 900 *42, 900 34, 400 0m 8700 6350 10300 7600 14100 10450 *20000 15050 0' 19, 200 14, 000 22, 700 16, 800 31, 000 23, 000 *44, 100 33, 200 -1. 5m 9450 6950 10200 7500 13900 10250 *19500 14850 -5' 20, 900 15, 300 22, 500 16, 600 30, 600 22, 600 *43, 000 32, 700 -3. 0m *10900 8150 *13750 10300 *17900 14950 -10' *24, 000 18, 000 *30, 300 22, 700 *39, 500 38, 000 -4. 6m *10650 *10650 *14750 *14750 -15' *23, 500 *23, 500 *32, 500 *32, 500

4. 6m 15' Cf Cs

*22450 *49, 500

*22450 *49, 500

*14500 *32, 000 *22400 *49, 400 *23150 *51, 000 *19450 *42, 900 *13550 *29, 800

*14500 *32, 000 *22400 *49, 400 *23150 *51, 000 *19450 *42, 900 *13550 *29, 800

*11950 *26, 400 *20950 *46, 200 *23850 *52, 600

*11950 *26, 400 *20950 *46, 200 *23850 *52, 600

5540 18'2"

4. 6m 15' Cf Cs

1370 4'6"

3295 10'10"

unit: kg lb 3. 0m 10' Cf Cs

3075 10'1"

46 1. 8"

4250 13'11"(4600 15'1") 5370 17'7"(5720 18'9")

600 23. 6"

790 2'7"

3300 10'10" 3900 12'10" *3190 10'6" *When retracted

*24750 *54, 600

*24750 *54, 600

LOADING SHOVEL WORKING RANGE AND BUCKET SELECTION

Working Range

11 10 9 8 7

Type of bucket Capacityheaped A B C D E F G Max. digging reach at ground level Level crowding distance Min. crowd distance

Bottom dump 4. 0 m3 10090 mm 6705 mm 3495 mm 9190 mm 8850 mm 3275 mm 5135 mm 5. 2 yd3 33'1" 22'0" 11'6" 30'2" 29'0" 10'9" 16'10"

*15900 *35, 000 *24350 *53, 700 *25750 *56, 800 *21750 *47, 900 *15300 *33, 700

*15900 *35, 000 24000 52, 900 24400 53, 800 *21750 *47, 900 *15300 *33, 700

*13100 *28, 900 *22800 *50, 300 *26700 *58, 900

*13100 *28, 900 *22800 *50, 300 *26700 *58, 900

4. 6m 15' Cf Cs

unit: kg lb 3. 0m 10' Cf Cs

A B

6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 0 1

Bucket digging force Arm crowd force

386 kN 39400 kg 86, 860 lb 338 kN 34500 kg 76, 660 lb

Bucket Selection

Type of bucket Capacityheaped Width Weight No. [. . . ]