Detailed instructions for use are in the User's Guide.

[. . . ] ®

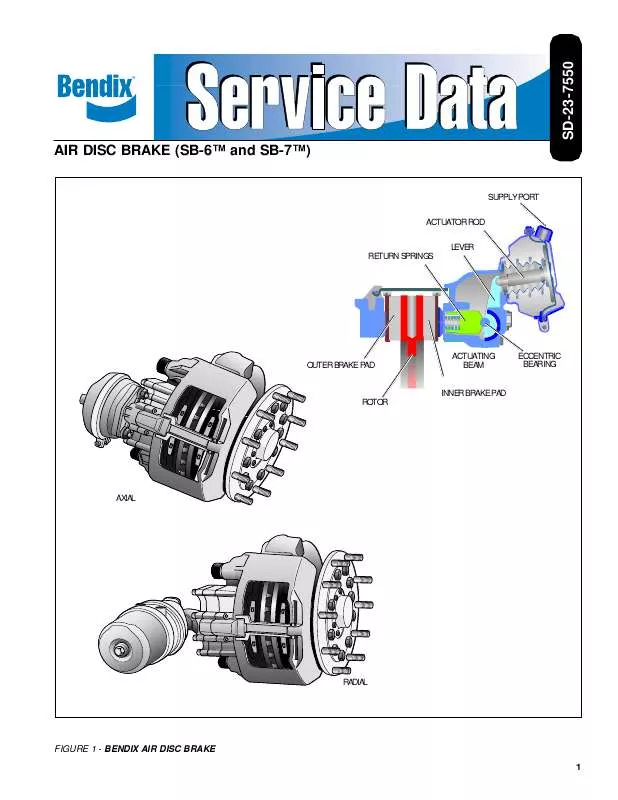

AIR DISC BRAKE (SB-6TM and SB-7TM)

SUPPLY PORT ACTUATOR ROD LEVER

RETURN SPRINGS

OUTER BRAKE PAD

ACTUATING BEAM INNER BRAKE PAD

ECCENTRIC BEARING

ROTOR

AXIAL

RADIAL

FIGURE 1 - BENDIX AIR DISC BRAKE

SD-23-7550

1

Index

Page 1 1. 1 1. 2 1. 2. 1 1. 3 1. 4 1. 4. 1 1. 5 2 2. 1 2. 2 2. 3 2. 4 3 3. 1 3. 2 3. 2. 1 3. 2. 2 3. 2. 3 3. 3 3. 4 3. 4. 1 3. 4. 2 3. 4. 3 4 Exploded view of brake Axial Disc Brake Components Axial Disc Brake Repair Kits Axial Disc Brake Wear Indicator Kits Radial Disc Brake Components Radial Disc Brake Repair Kits Radial Disc Brake Wear Indicator Kits Brake Disc Rotor General information (for "Axial- and Radial Disc Brake") Service Tools Diagnostic Equipment Lubrication Torque requirements Description and Function Axial Disc Brake Sectioned View Description of operation Brake actuation Brake release Brake adjustment (automatic) Radial Disc Brake Sectioned View Description of operation Brake actuation Brake release Brake adjustment (automatic) Safety instructions for service work (for "Axial- and Radial Disc Brake") Brake Testing (for "Axial- and Radial Disc Brake") Troubleshooting procedure Adjuster check Wear limits of Brake Pads and Rotor Brake wear check using Guide Pin (for Calipers with standard Guide Pins) Brake wear check using Guide Pin (for Calipers with long Guide Pins) Wear Indicators Diagnostic-Equipment - Hand held device ZB9031 Diagnostic-Equipment - Vehicle mounted device ZB9033 Pad replacement (for "Axial- and Radial Disc Brake") Pad removal Tappet Boot check Caliper floatation check Pad fitting Tappet with Boot replacement (for "Axial- and Radial Disc Brake") Tappet with Boot removal Adjuster thread inspection Tappet with Boot fitting Caliper Suspension Sealing (for "Axial- and Radial Disc Brake") 4 5 5 6 7 7 8

9 9 9 9

10 11 11 11 11 12 13 13 13 13 13

5 5. 1 5. 2 5. 3 5. 3. 1 5. 3. 2 5. 3. 3 5. 4 5. 5 6 6. 1 6. 1. 1 6. 1. 2 6. 2 7 7. 1 7. 1. 1 7. 2 8

14 15 16 18 19 20 21 21

22 22 23 23

24 25 25 27

2

9 9. 1 9. 2 10 10. 1 10. 2 10. 2. 1 10. 2. 2 11

Guide Pin Bushing replacement (for "Axial- and Radial Disc Brake") Brass Bushing replacement Rubber Bushing replacement Caliper replacement (for "Axial- and Radial Disc Brake") Caliper removal Caliper fitting Caliper with Rubber Boot (10) Caliper with Steel Cap (10a) Carrier replacement (for "Axial- and Radial Disc Brake") Actuation cylinder replacement (for "Axial- and Radial Disc Brake") Brake Chamber removal Brake Chamber fitting Spring Brake removal Spring Brake fitting Additional Information Service Video Service Tool Kit Diagnostic Equipment General Safety Guidelines Personal Notes

28 28 28

29 30 30 31 32

12 12. 1 12. 2 12. 3 12. 4 13 13. 1 13. 2 13. 3 13. 4

33 33 34 34

35 35 35 36

3

1 Exploded views

1. 1 Axial Disc Brake Components (for Wear Indicatators Kits see 1. 2. 1)

44 26 11 45

12

18/1

Assembly grease (coloured)

18/2 1 13

6*)

37 39 4 7 5 9 40 31 10 31a *) ) 10a * 2 58 161

Assembly grease (white)

1 2 4 5 6 7 9 10 10a 11 12 13 18/1

Caliper Carrier Sleeve Sleeve Rubber Bushing Brass Bushing Inner Boot Outer Boot Steel Cap Pad Retainer Pad Tappet with Boot Spring Brake

18/2 26 31 31a 37 39 40 44 45 58 161

Brake Chamber Spring Clip Outer Boot Clip O-Ring Adjuster Cap Caliper Bolt Caliper Bolt Pad Retainer Pin Washer Ring Tappet Bushing

VF 00127/12-ÄiO1

*) possible variants by items 10a & 31a

4

1. 2

Axial Disc Brake Repair Kits

CAUTION

Use only Genuine Bendix® parts The following Repair Kits are available Description Carrier Guide Kit Carrier Guide Kit (Steel Cap) Wear Indicator Kit (per axle) Guide Pins Kit Guide Pins Kit (Steel Cap) Seal Kit for Guide Pins Tappet and Boot Kit (2 pcs) Pad Set (per axle) Adjuster Cap (4 pcs) Pad Retainer Kit (per axle) Pad Retainer Kit (per axle) wear sensor Kit for Floating Pin Outer Guide Seal Kit (10 pcs) Kit for Fixed Pin Kit for Steel Cap Screw Kit for Steel Cap Screw Kit for Outer Boot Exchange Caliper r. h. only in assembled condition Exchange Caliper l. h. 1. 2. 1 Axial Disc Brake Wear Indicator Kits (Typical kits are shown below) Type 1 Contents 2, 4, 5, 31, 39, 40 2, 4, 5, 10a, 31a, 39, 40 for variants see 1. 2. 1 with or without 104 4-7, 9, 10, 31, 39, 40, 58 4, 5, 6, 7, 9, 10a, 31a, 39, 40, 58 9, 10, 31, 37, 58 13, 161 12, 26, 37, 44, 45 37 11, 26, 44, 45 11, 26, 44, 45, 104, 115, 116 4, 6, 39 10, 31 5, 7, 9, 10a, 31a, 40, 58 10a, 31a 10a, 31a, 39, 40 10, 31, 39, 40 Association of Repair Kits to the Disc Brakes and Repair Kit's Order no.

see www. Bendix. com for more information

http://www. Bendix. com

see Type plate on the Caliper

Type 4

Type 2

Type 5

Type 3

101 102 104 112

Sensor 115 Sensor 116 Cable Protection Plate 117 Clip 119 120

Spring Washer Screw Wear Indicator Cable Bracket Bracket

5

1. 3 Radial Disc Brake Components (for Wear Indicator Kits see 1. 4. 1)

1 2 4 5 6 7 9 10 10a 11 12 13 18/1 18/2

Caliper Carrier Sleeve Sleeve Rubber Bushing Brass Bushing Inner Boot Outer Boot Steel Cap Pad Retainer Pad Tappet with Boot Spring Brake Brake Chamber

26 31 31a 37 39 40 44 45 58 161

Spring Clip Outer Boot Clip O-Ring Adjuster Cap Caliper Bolt Caliper Bolt Pad Retainer Pin Washer Ring Tappet Bushing

*) possible variants by items 10a & 31a

6

1. 4

Radial Disc Brake Repair Kits

CAUTION:

Use only Geniune Bendix parts The following Repair Kits are available Description Carrier Guide Kit Carrier Guide Kit (Steel Cap) Wear Indicator Kit (per axle) Guide Pins Kit Guide Pins Kit (Steel Cap) Seal Kit for Guide Pins Tappet and Boot Kit (2 pcs) Pad Set (per axle) Adjuster Cap (4 pcs) Pad Retainer Kit (per axle) Pad Retainer Kit (per axle) wear sensor Kit for Rubber Sleeve Outer Guide Seal Kit (10 pcs) Repair Kit Kit for Steel Cap Screw Kit for Steel Cap Screw Kit for Outer Boot Exchange Caliper r. h. only in assembled condition Exchange Caliper l. h. [. . . ] Use only 8mm Box End Wrench or 1/4" drive Socket with a lever length no greater than 4 in. DO NOT use an Open Ended Wrench since this may damage the Adjuster shaft. Rotate the Adjuster clockwise until the Pads come into contact with the Rotor. Then turn back the Adjuster 2 clicks.

12

M+P-KN-014

23

The hub should turn easily by hand after having applied and released the brake. The Cap (37) must then be replaced after it has been lightly greased it with Renolit HLT2 (available as part number II14525). After setting the Pad Retainer (11) into the groove of the Caliper (1), it must be pushed in to allow the insertion of the Pad Retainer Pin (44). Fit washer (45) and Spring Clip (26) to the Pad Retainer Pin (44) (use only new parts). Our recommendation is to fit the Washer (45) and Spring Clip (26) pointing downwards (see diagram). Wheel mounting (refer to Vehicle Manufacturer's recommentations).

44 11 45 26

M+P-KN-016

1

IMPORTANT!

As with all brake pad replacements, new Pads require a break-in period. Heavy or or prolonged braking should be avoided during this break-in period. Follow Industry recommendations to determine the optimum break-in period for the vehicle.

7 Tappet with Boot replacement

(for "Axial- and Radial Disc Brake") 7. 1 Tappet with Boot removal Note: It may be easier to remove the Caliper from the axle for replacement of the Tappets (see Section 10. 1).

The Adjuster (23) must be screwed clockwise until the Boots can be reached. Exercise caution to avoid thread overrun if the Caliper has been removed from the vehicle (see setion 7. 1. 1. ).

13

To remove the Tappet Boot from the Caliper bore, a Screwdriver should be used to deform the Boot location ring - see diagram.

13

M+P-KN-017

CAUTION!

Because it is not a replacement item, use caution to avoid damage to the Inner Seal.

24

The Tappets (13) can be removed from the Threaded Tubes by using Wedge Fork A. Check Inner Seal (arrow) and if damaged, replace the Caliper.

A

13

A 13

7. 1. 1 Adjuster thread inspection Place an new thickness Pad (12) into the outboard gap to avoid overrunning of the Threaded Tubes.

161

VF 00127/4

IMPORTANT!

Threaded Tubes should not be extended beyond thread engagement of the Bridge. If thread engagement (synchronization) is lost, the Caliper must be replaced. For the inspection of the threads, the tubes must be screwed out (max. [30mm]) by turning the Adjuster (23) clockwise. If Caliper is not installed on axle, put a spacer E (length = 2. 76in. [70mm]) into the Caliper (1) to avoid overrunning of the Threaded Tubes (16) when adjusting them out (see illustration opposite). During adjusting, the threads can be checked for corrision damage. In case of water ingress or corrosion, the Caliper must be replaced.

12 16 46

M+P-KN-019

70 mm

16

7. 2 Tappet with Boot installation With Caliper fixed to axle: Grease threads with RENOLIT HLT2 (Order No. Screw back Threaded Tubes (16), by turning the Adjuster (23) counter-clockwise. Place new Tappet Bushing (161) onto the head of the Tube (16). [. . . ] A 1 inch bubble in 1 minute is acceptable, otherwise repair/replace components as necessary.

13 Additional information

13. 1 Service Video A Video is available for additional information. Order number: RA-SB0002. EN Video (English) RA-SB0002. FR Video (French) RA-SB0002. PO Video (Portugese) RA-SB0002. SP Video (Spanish)

13. 2 Service Tool Kit ZB 9032 For service and repair work we recommend our BendixTool Kit ZB 9032 II 37951/004EX, which contains all the necessary special tools. 13. 3 Diagnostic Equipment For vehicles fitted with continuous potentiometer type wear sensors, Bendix Diagnostic Equipment may be used to ensure quick and simple measurement of wear at each caliper. See sections 5. 4 and 5. 5.

35

13. 4 General Safety Guidelines. [. . . ]