Detailed instructions for use are in the User's Guide.

[. . . ] This display also provides the user interface for the optional AccuGrade™ Grade Control System. The Selectable Work Speed Control, Selectable Implement Control and Selectable Hystat Response Control modes allow the operator to “dial in” his machine to maximize production.

Additional Features for Maximum Comfort

• Air ride seat available for an unparalleled level of comfort in a compact track loader. • Optional air conditioner and heater for greater comfort in extreme conditions. [. . . ] Planetary final drive motors improve torque and drawbar performance, delivering more power to the ground. Steel rollers with metal face seals provide maximum protection for wheel bearings resulting in long-term durability and reliability in even the toughest conditions. The simple recoil grease tensioning system allows quick track tension adjustment.

4

Power Train

Aggressive performance with fuel efficiency.

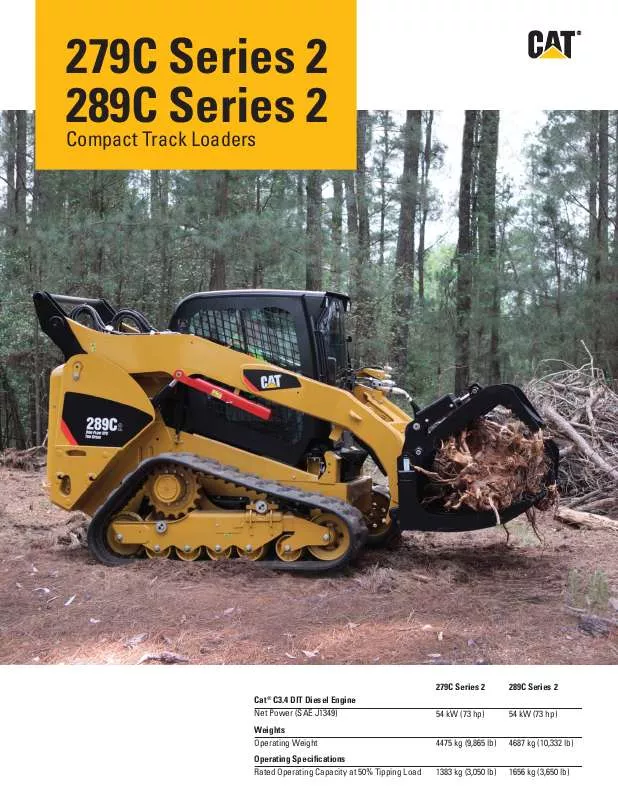

Cat Engine

The high performance power train provides high engine horsepower and torque. The machines feature the Cat C3. 4 DIT engine – a rugged, reliable engine that meets U. S. EPA Tier 4 Interim/EU Stage IIIA emission requirements.

Hand and Foot Throttles

Hand and foot throttles allow the operator to match engine speed to the task. The hand throttle is ideal for jobs requiring constant engine speed such as cold planing, trenching or snow blowing. The foot throttle lets the operator vary engine speed and minimize fuel consumption for other tasks such as load and carry, truck loading, grading and dozing.

Electronic Torque Management

The Electronic Torque Management system maximizes power to the ground and prevents the engine from stalling in tough digging and dozing applications for maximum productivity. The system allows part throttle operation which provides smoother machine operation and reduces fuel consumption.

Lift Linkages

Built for tough working conditions.

Choice of Lift Designs

Two types of lifting arrangements are available – vertical lift (path #1 above) and radial lift (path #2) – to meet your specific application needs.

Selectable Work Speed Control

The optional Selectable Work Speed Control lets you select the ground speed that is best suited for the application. This feature is useful in operations such as trenching and cold planing that require precise machine control at relatively slow and constant speeds.

Selectable Hystat Response Control

The optional Selectable Hystat Response Control lets the operator select one of three modes to match the machine’s drive response to the operator’s preference, skill level and application requirements.

Vertical Lift

The 287C Series 2 features the vertical lift design which provides extended reach and lift height for quick and easy truck loading and material placement. The lift height is 3239 mm (127 in) on the 289C Series 2.

Radial Lift

The 279C Series 2, with its radial lift design, delivers excellent digging performance and superior mid-lift reach.

5

Work Tools

Do more jobs with one machine using Cat® Work Tools.

The Right Tool for the Job

Designed and built for optimum performance and durability, Cat Work Tools deliver high productivity in a variety of applications to maximize versatility: • Augers • Backhoes • Blades (angle, dozer) • Buckets (general purpose, high capacity, dirt, utility, light material, multi purpose, industrial grapple, utility grapple) • Brooms (angle, pickup, utility) • Brushcutters • Cold Planers • Forks (pallet, industrial grapple, utility grapple, utility) • Hydraulic Hammers • Landscape Tillers • Landscape Rakes • Material Handling Arm • Mulcher • Power Box Rakes • Shear • Snow Blowers • Stump Grinders • Trenchers • Vibratory Compactors • Wheel Saws

Quick Couplers

Work tools can be changed quickly and easily with the Cat Compact Track Loader’s quick coupler system. The standard quick coupler features manual engagement and disengagement of work tools using two high leverage handles. The optional hydraulic quick coupler allows the operator to quickly change tools without leaving the cab. AccuGrade™ Grade Control System for Skid Steer, Multi Terrain and Compact Track Loaders Common to AccuGrade systems for Track-Type Tractors and Motor Graders, this deeply integrated solution automates the machine’s electrohydraulic controls to achieve a consistent grade across the work site, improve accuracy and increase productivity, ultimately lowering operating and material costs.

6

Serviceability

Simplified service and maintenance save you time and money.

Easy Service

Convenient service features make maintenance easy, reducing your downtime: • Rear door opens 90 degrees for easy access to both sides of the engine. • Cooling package tilts up to provide excellent access to the engine compartment. [. . . ] Lift 371 mm 1981 mm 1762 mm 1458 mm 2238 mm 1282 mm 85° 14. 6 in 1625 mm 2129 mm 2960 mm 3679 mm 2117 mm 4081 mm 3239 mm 195 mm 781 mm 2456 mm 231 mm 44° 50° 78. 0 in 69. 4 in 57. 4 in 88. 1 in 50. 5 in 64 in 83. 8 in 116. 5 in 144. 8 in 83. 3 in 160. 7 in 127. 5 in 7. 7 in 30. 7 in 96. 7 in 9. 1 in

10

279C Series 2 and 289C Series 2 Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

ELECTRICAL 12 volt Electrical System 90 ampere Alternator Automatic Glow Plug Activation Ignition Key Start/Stop Switch Lights: Gauge backlighting, two rear tail lights, two rear halogen working lights, two adjustable front halogen lights, dome light Backup Alarm Heavy Duty Battery, 880 CCA OPERATOR ENVIRONMENT Gauges: Fuel level, hour meter Operator Warning System Indicators: Air filter restriction, alternator output, armrest raised/operator out of seat, engine coolant temperature, engine oil pressure, glow plug activation, hydraulic filter restriction, hydraulic oil temperature, parking brake engaged Vinyl seat, mechanical suspension Fold-in Ergonomic Contoured Armrest Control Interlock System, when operator leaves seat or armrest raised: Hydraulic system disables, hydrostatic transmission disables, parking brake engages ROPS Cab, Open, Tilt Up FOPS, Level I Top and Rear Windows Headliner, Deluxe Floor Mat Interior Rear View Mirror 12 volt Electric Socket Horn POWER TRAIN

Cat C3. 4 DIT Diesel Engine (meets U. S.

EPA Tier 4 Interim/EU Stage IIIA emission

standards)

Air Cleaner, Dual Element, Radial Seal

S•O•SSM Sampling Valve, Hydraulic Oil

Filters, Spin-on, Hydraulic

Filters, Bayonet-type, Fuel and Water Separator

Tilt Up Radiator/Hydraulic Oil Cooler

Spring Applied, Hydraulically Released,

Wet Multi Disc Parking Brake

Hydrostatic Transmission, 2 Speed

OTHER

Suspension, Torsion Axles

Engine Enclosure, Lockable

Extended Life Antifreeze, –37° C (–34° F)

Machine Tie Down Points (4)

Support, Lift Arm

Hydraulic Oil Level Sight Gauge

Radiator Coolant Level Sight Gauge

Radiator, Expansion Bottle

Cat ToughGuard™ Hose

Auxiliary, Hydraulics, Continuous Flow

Heavy Duty, Flat Faced Quick Disconnects

Split D-Ring to Route Work Tool Hoses

Along Side of Left Lift Arm

Electrical Outlet, Beacon

Belly Pan Cleanout

Variable Speed Demand Fan

MANDATORY EQUIPMENT

Hydraulics, Standard or High Flow XPS

Quick Coupler, Mechanical or Hydraulic

Seat Belt, 50 mm (2 in) or 75 mm (3 in)

Comfort Package

(must select one of the following):

• Open ROPS (C1): Radio Ready,

Suspension Seat (no heater or door)

• Enclosed ROPS with Heat (C2):

Cup Holder, Radio Ready, Seat

(choice of Suspension or Air Ride),

Heater and Defroster, Side Windows,

Door (either Glass or Polycarbonate)

• Enclosed ROPS with A/C (C3): Features of C2 Package plus Air Conditioner Performance Package (must select one of the following): • TL1: Two Speed • TL2: Two Speed, Self Level • TL3: Two Speed, Self Level, Advanced Machine Information and Control System (AMICS)

279C Series 2 and 289C Series 2 Optional Equipment

Optional equipment may vary. [. . . ]