Detailed instructions for use are in the User's Guide.

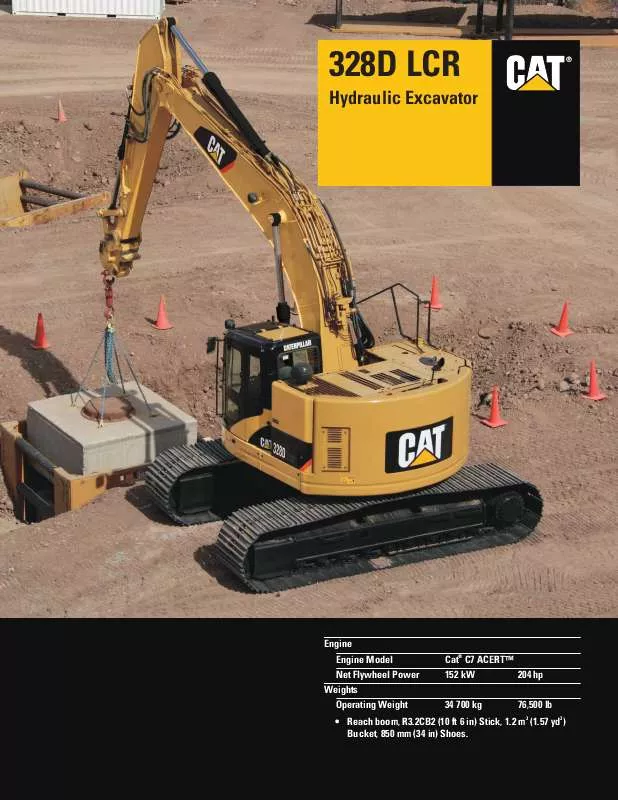

[. . . ] 328D LCR

Hydraulic Excavator

®

Engine Engine Model Net Flywheel Power Weights Operating Weight

Cat® C7 ACERTTM 152 kW 204 hp 34 700 kg 76, 500 lb

· Reach boom, R3. 2CB2 (10 ft 6 in) Stick, 1. 2 m3 (1. 57 yd3) Bucket, 850 mm (34 in) Shoes.

328D LCR Hydraulic Excavator

The D Series incorporates innovations for improved performance and versatility.

C7 with ACERTTM Technology ACERTTM Technology works at the point of combustion to optimize engine performance and provide low exhaust emissions to meet U. S. EPA Tier 3 emission regulations, with exceptional performance capabilities and proven reliability. 4

Hydraulics

Operator Station

The hydraulic system has been designed Provides maximum space, wider to provide reliability and outstanding visibility and easy access to switches. An optional Tool The monitor is a full-color graphical Control System provides enhanced display that allows the operator to flexibility. [. . . ] A new optional air suspension seat is available in the 328D LCR. The standard and optional seats provide a variety of adjustments to suit the operator's size and weight including fore/aft, height and weight. Wide adjustable armrests and a retractable seat belt are also included. The joystick controls are designed for low lever effort and match operator's natural wrist and arm position. The operator can operate the joystick controls with an arm on the armrest. Horizontal and vertical strokes have been designed to reduce operator fatigue.

7

Structures

328D LCR structural components and undercarriage are the backbone of the machine's durability.

Robotic Welding. Up to 95% of the structural welds on a Caterpillar® Excavator are completed by robots. Robotic welds achieve over three times the penetration of manual welds. X-shaped, box-section carbody provides excellent resistance to torsional bending. Robot-welded track roller frames are press-formed, pentagonal units to deliver exceptional strength and service life.

Main Frame. Rugged main frame is designed for maximum durability and efficient use of materials. The swing bearing utilizes cross roller bearings versus the traditional ball bearing design. The cross roller bearing design allows for more surface contact to absorb the stresses that are a result of the high swing torque that Cat offers. It provides exceptional machine stability and reduces machine pitching during boom down operation.

Undercarriage. Durable Cat undercarriage absorbs stresses and provides excellent stability. Sealed and lubricated track rollers, carrier rollers, and idlers provide excellent service life, to keep the machine in the field longer. The long (L) undercarriage maximizes stability and lift capacity. Two additional track links have been added to the 328D LCR. This long, wide, and sturdy undercarriage offers a very stable work platform.

8

Booms, Sticks and Bucket Attachments

Designed for maximum flexibility, productivity and high efficiency on all jobs, the 328D LCR offers a wide range of configurations suitable for a variety of applications.

Reach Boom. The reach boom features an optimum design that maximizes digging envelopes with three stick choices: R3. 2CB2 Stick. The CB-family buckets associated with these sticks have enough capacity for excellent reach and depth in trenching and general construction applications.

R2. 65CB2 Stick. Stick is suited to high-capacity buckets used in trenching, excavation, and other general construction work. [. . . ] Front linkage fully extended at ground line 2. 100% bucket fill factor * Capacities based on SAE J296. Some calculations of capacity fall on borderlines. Rounding may allow two buckets to have the same English rating but different metric ratings.

2100 kg/m3 (3, 500 lb/yd3) max material density 1800 kg/m3 (3, 000 lb/yd3) max material density 1500 kg/m3 (2, 500 lb/yd3) max material density 1200 kg/m3 (2, 000 lb/yd3) max material density Not Available

18

328D LCR Hydraulic Excavator specifications

328D LCR Work Tool Matching Guide

Boom Options Stick Options Hydraulic Hammer R3. 2CB2 m (10'6") H120Cs/ H130Cs/ H140Cs CVP110 MP15/MP20 S320 3. 1 m3/4 yd3 yes yes yes yes Reach Boom 6. 15 m (20'2") R2. 65CB2 m (8'8") H120Cs/ H130Cs/ H140Cs CVP110 MP15/MP20 S320/S325 3. 1 m3/4 yd3 yes yes yes yes

Vibratory Plate Compactor Multi-Processor 360 Scrap Shear Trash Grapple Contractors' Grapple Hydraulic Thumb Dedicated Quick Coupler Pin-Grabber Quick Coupler

328D LCR Hydraulic Excavator specifications

19

Reach Boom Lift Capacities

Load Point Height Load Radius Over Front Load Radius Over Side Load at Maximum Reach

R2. 65CB2 STICK 2650 mm (8'8") BUCKET 1. 2 m3 (1. 57 yd3)

3. 0 m (10. 0 ft) 4. 5 m (15. 0 ft)

UNDERCARRIAGE Long SHOES 850 mm (34") triple grouser

6. 0 m (20. 0 ft) 7. 5 m (25. 0 ft) 9. 0 m (30. 0 ft)

BOOM Reach HEAVY LIFT Off

m ft 9. 0 m 30. 0 ft 7. 5 m 25. 0 ft 6. 0 m 20. 0 ft 4. 5 m 15. 0 ft 3. 0 m 10. 0 ft 1. 5 m 5. 0 ft Ground Line 1. 5 m 5. 0 ft 3. 0 m 10. 0 ft 4. 5 m 15. 0 ft kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb *9900 *22, 500 *16 750 *36, 350 *12 150 *25, 950 *9900 *22, 500 *16 750 *36, 350 *12 150 *25, 950 *10 550 *22, 600 *13 050 *28, 050 *14 700 *31, 750 *15 000 *32, 550 *14 300 *30, 950 *12 550 *27, 150 *9350 *19, 850 *10 550 *22, 600 11 200 24, 100 10 450 22, 500 10 150 21, 800 10 100 21, 700 10 250 22, 000 *9350 *19, 850 *6900 *15, 200 *7350 *16, 000 *8350 *18, 050 *9550 *20, 600 *10 500 *22, 650 *10 900 *23, 600 *10 650 *22, 950 *9450 *20, 300 *6400 *6900 *15, 200 *7350 *16, 000 7600 16, 300 7200 15, 450 6850 14, 700 6600 14, 200 6500 14, 000 6600 14, 150 *6400 *6800 *14, 900 *7200 *15, 650 *7750 *16, 850 *8250 *17, 850 8450 18, 100 *8150 *17, 450 5350 11, 400 5250 11, 200 5050 10, 800 4850 10, 400 4750 10, 150 4700 10, 050 *5150 *5800 3650 3600 *3950 *8, 750 *3600 *7, 950 *3500 *7, 700 *3550 *7, 750 *3650 *8, 050 *3950 *8, 650 *4350 *9, 600 *5100 *11, 200 *5350 *11, 650 *6150 *13, 450 *3950 *8, 750 *3600 *7, 950 *3500 *7, 700 3300 7, 250 3100 6, 850 3100 6, 850 3300 7, 250 3750 8, 300 4750 10, 550 *6150 *13, 450 7. 16 22. 96 8. 48 27. 56 9. 30 30. 37 9. 76 31. 97 9. 93 32. 58 9. 83 32. 26 9. 45 31. 00 8. 75 28. 66 7. 63 24. 90 6. 09 19. 72

* Limited by hydraulic capacity rather than tipping load. [. . . ]