Detailed instructions for use are in the User's Guide.

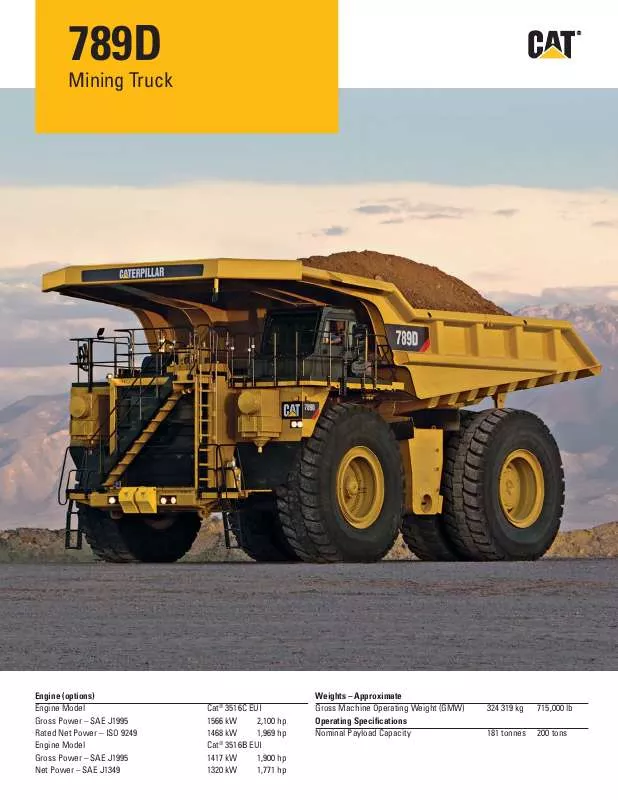

[. . . ] · Application specific capabilities for extreme ambient conditions, high altitude applications, and extra quiet machine to reduce spectator sound levels. · A variety of Cat Truck Bodies are available including Mine Specific Design (MSD II), X, Combination, Gateless Coal and Dual Slope bodies.

Contents

Power Train Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power Train Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Engine/Power Train Integration. . . . . . . . . . . . . . . . . . . . . . . . 5

Structures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operator's Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cat Brake System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Truck Body Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Monitoring System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Sustainability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Serviceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Standard Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Optional Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2

Power Train Engine

Engine

Both the Cat® 3516B and 3516C EUI Quad turbocharged diesel engines deliver high power and reliability in the world's most demanding mining applications.

The Cat ® 3500 series engines are built for power, reliability and efficiency for superior performance in the toughest applications.

Design

The 3500 series engines are 16-cylinder, four-stroke designs that uses long, effective power strokes for more complete fuel combustion and optimum efficiency.

EPA Compliant

Where applicable, the 3516C engine is compliant with U. S. Environmental Protection Agency emissions requirements.

High Torque Rise

The 23% net torque rise provides unequalled lugging force during acceleration, on steep grades and in rough underfoot conditions. Torque rise effectively matches transmission shift points for maximum efficiency and fast cycle times.

Enhanced Life

High displacement, low rpm rating, and conservative horsepower ratings mean more time on the haul roads and less time in the shop.

3516B Separate Circuit Aftercooler

Allows the aftercooler circuit to operate cooler than jacket water temperature for a denser air charge and greater combustion efficiency.

3516C Air to Air Aftercooler (ATAAC)

The 1566 kW (2, 100 hp) engine option uses an Air To Air Aftercooler to achieve an even greater reduction in air intake temperatures. [. . . ] Based off of the dual slope design for customers who need a flexible body to haul light ore (such as coal) and light, well fragmented overburden. 5) Dual Slope Body The original standard body, the Dual Slope body, provides excellent load retention, maintains a low center of gravity with optimum load distribution, reduces shock loading and is available in lined and unlined configurations. The Dual Slope body is intended for tough applications including greenfield sites and contracting mines.

Custom Body Options

A variety of options including tail extensions, sideboards, tumble bars, rock boxes and rock shedders are available to maintain rated payload, reduce spillage and improve hauling efficiencies.

9

Monitoring System

VIMS PC ET

Vital machine health and payload data keeps the 789D performing

at peak production levels.

VIMSTM Monitoring System

Intelligent Caterpillar designed machine monitoring system provides critical machine health and payload data in realtime to keep the 789D performing at top production levels. This system is translated and available in most of the major international languages.

VIMS

Production Management

Production Management enhances truck/loading tool effectiveness, improves fleet productivity and helps extend the life of truck frames, tires, rims and power train components, while lowering operating and maintenance cost.

Payload Management

Max Payload Speed Manager is a feature that aids in managing the Cat 10/10/20 Overload Policy. Based on target payload weight and overload settings, the VIMS system logs and warns the operator when the truck reaches overload after 2nd gear reweigh. The truck will be limited to 2nd gear at 1, 750 rpm, and the automatic retarder speed setting is reduced to 1, 750 rpm until the load is dumped. Payload management enables the manager to enhance truck/loading tool effectiveness and productivity levels by preventing overloads that can cause damage to component life and affect operator safety.

Payload Weight Distribution

Percentage of Total Loads

Road Analysis Control (RAC)

Optional system monitors haul road conditions by measuring frame rack, pitch, and bias to improve haul road maintenance, cycle times, tire life, and fuel efficiency.

VIMS-PC

Payload Weight (Tons)

Recommended Payload Range Inefficient Payload Ranges

With Production Management Without Production Management

VIMS-PC, the off-board reporting software program, allows service personnel to download a complete record of machine health and productivity data to a laptop computer for diagnosis and analysis. Easy-to-use software enables service technicians and mine management to generate health and payload reports for more effective machine management.

VIMS Supervisor

Optional software allows mine management to easily manage and interpret VIMS data for optimum fleet management and productivity.

Machine Management

Service technicians or mine personnel can download data and generate reports for better machine management. Data can be used to improve effectiveness of scheduled maintenance programs, maximize component life, improve machine availability, and lower operating costs.

10

Safety

Product Safety

Cat mining machines and systems are designed with safety as their first priority.

Caterpillar has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and system designs.

Mining Technologies

Cat® MineStarTM System encompasses a comprehensive suite of mining technologies grouped within a number of configurable capability sets, including Fleet, Terrain, Detect, Health, and Command. Object Detection is part of the Detect capability set and provides customers with a scalable system to aid in the awareness of machines and other objects in the near vicinity of working equipment. Object Detection systems are factory installed as standard equipment on 789D mining trucks. The fully integrated Object Detection system, RADAR AND CAMERA, provides both audible and visual indications of detected objects using radars which surround the machine, along with cameras on each side to allow the operator to confirm the detected object. The cameras supplement the radar alerts and are selectable by touch screen menus through an intuitive interface.

Overload Policy

Adherence to the Caterpillar 10/10/20 Overload Policy assures that steering and braking systems have sufficient capacity to perform.

Standard Safety Features

Slip resistant surfaces, retractable, seat/shoulder belts with three-point operator restraint, wide-angle mirrors, body raised indicator, body retaining cable, guard rails, reverse neutralizer when dumping, low interior sound level, secondary steering system, ground level access shutoff switches.

SAFETY. CAT. COMTM

11

Sustainability

Sustainability Features

A variety of features improve sustainability in areas of decreasing waste, extending component life and lowering emissions levels.

The 789D Mining Truck offers oil renewal systems, extended life filters and extended maintenance intervals which aid in decreasing the amount of waste contributed to our environment.

Oil Renewal System

Optional oil renewal system extends engine oil change intervals from 500 hours to 4, 000 hours or more to increase machine availability and reduce costs.

Engines with Advanced Technology

Engines with advanced technology contribute less emissions to the environment while maintaining fuel efficiency.

Fuel Efficiency

The engine provides additional retarding by running against compression on downhill hauls. During retarding applications the engine ECM does not inject fuel into the cylinders for exceptional fuel economy.

12

Serviceability

Tie Off Points

Less time spent on maintenance means more time on the haul roads.

Enhances working environment during service of recommended maintenance areas.

Servicing Ease

Easy access to daily service points simplifies servicing and reduces time spent on regular maintenance procedures. Enhanced serviceability and 500-hour service intervals are designed to increase machine availability and productivity.

Maintenance Platform

Provides access to engine, steering hydraulic tank, and battery compartment.

In-Frame Access

Permits easy access to major components for easy servicing and removal.

Ground-Level Access

Allows convenient servicing to tanks, filters, drains, and engine shutdown. Ground-level VIMS data port permits easier downloading of information.

Autolube

Automatic lubrication system reduces maintenance time by automatically lubricating necessary components on a regular basis.

Fast Fill Service Center

Optional fast fill service center features high speed fuel and oil exchange.

Scheduled Oil Sampling

S·O·SSM sampling valves speed sampling and analysis reliability.

Pressure Test Points

Disconnect valves are conveniently located throughout the hydraulic systems for easy pressure testing.

Sealed Electrical Connectors

Electrical connectors are sealed to lock out dust and moisture. Wires are color coded for easy diagnosis and repair.

Cylinder Heads

Individual cylinder heads are interchangeable for easy removal and visual inspection of internal parts.

On-Board Diagnostic Systems

The VIMS system continuously monitors all critical machine functions and components to help locate faults quickly for faster repair.

13

Customer Support

Commitment Makes the Difference

Cat dealers have what it takes to keep mining haul trucks productive.

Cat dealers offer a wide range of solutions, services and products that help you lower costs, enhance productivity and manage your operation more efficiently. Support goes far beyond parts and service. From the time you select a piece of Cat equipment until the day you rebuild, trade or sell it, the support you get from your Cat dealer makes the difference that counts.

Dealer Capability

Cat dealers will provide the level of support you need, on a global scale. [. . . ] Usable rimpull will depend upon traction available and weight on drive wheels.

GROSS WEIGHT*

lb x

1000

N x

1000

0 0 1C

100 50

200 100

300 150

400 200

500 250

600 300

700

800 350

900 lb x 1000 400 kg x 1000

200 180 160 140 120 500 100 400 80 300 60 40 20 0 200 100 0 800 700 600

E

30%

L

25% 20%

RIMPULL

1D

15%

2D 3D 4D 5D 6D

10%

5%

0 0 5

10 10

20 15

30 20

40 25 30

50 35

60

40 mph

SPEED

*at sea level

TOTAL RESISTANCE (Grade Plus Rolling)

km/h

21

789D Mining Truck Specifications

Weight/Payload Calculation

(Example)

kg 69 900 18 370 10 425 98 695 lb 154, 100 40, 500 22, 980 217, 580 kg 69 900 18 370 10 425 98 695 30 132 7350 136 177 4085 Tonnes 184 lb 154, 100 40, 500 22, 980 217, 580 X Body 66, 430 16, 200 300, 210 9, 006 Tons 203 kg 69 900 18 370 10 425 98 695 lb 154, 100 40, 500 22, 980 217, 580

Chassis Tires (6) 37. 0-R57 Standard Rims (6) 29-57 Estimated Empty Chassis Weight2 Type of Truck Body Body Weight Fully Lined Body (Optional and Recommended) Estimated Operating Machine Weight2 3% Debris Allowance3

1

MSD Body 23 970 52, 845 6150 13, 560 128 815 283, 985 3864 8, 520 Tonnes 192 Tons 211

Dual Slope Body 26 610 58, 665 9707 21, 400 135 012 297, 645 4050 8, 929 Tonnes 185 Tons 204

Potential Target Payload

1 2

4

Includes: common arrangement, 100% fuel (2082 L/550 gal), fluids and standard mandatory attachments.

Weights will vary dependent on configuration and may include ±2% variation due to standard material tolerances.

3 Calculations include 3% debris allowance. However, actual debris allowance should be considered based upon known site conditions.

4 It is recommended to work with your Global Mining representative to calculate target payload per specific site.

22

789D Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

POWER TRAIN Diesel engine/turbocharged/aftercooled: Ground level engine shutdown Ether starting aid (automatic) Aftercooler (separate circuit or air to air) Elevated low idle control Automatic starter protection Multi-point all pressure sensing Braking system: Brake release motor (towing) Oil-cooled, multi-disc (front and rear) (service retarding, parking, secondary) Automatic Retarder Control Engine overspeed protection Extended life brake disc material Transmission: 6-speed, automatic powershift with

electronic control (TCC)

Controlled throttle shifting Individual clutch modulation Body-up shift inhibitor Directional shift management Downshift/reverse shift inhibitor Oil level sensor Neutral start switch/coast inhibitor Body-up reverse neutralizer Programmable top gear Lock-up torque converter Rear axle continuous lubrication/

filtration

ELECTRICAL Alarm, backup Alternator, 105 amp Batteries, 12V (2), 93 amp-hour Converter, 12V electrical Electrical system, 24V, 15 amp Lighting system: Backup and hazard lights Auxiliary work lights (2) rear, (1) RH side, (1) LH side Directional signals (front and rear LED) Engine compartment lights External payload lights Headlights with lo-hi beam selector Ladder light and service deck lights Left-hand ladder/service deck Stop/tail lights (LED) VIMS, blue light (LED) OPERATOR ENVIRONMENT STANDARD CAB Operator seat Non-suspension trainer seat Flip down front visor Standard side of cab access DELUXE CAB Heated and ventilated operator seat Suspension trainer seat Retractable front visor Rear of cab access and standard side of cab access Vacuum, cab clean-out Operator Footrest DELUXE COLD WEATHER CAB Heated and ventilated operator seat Suspension trainer seat Retractable front visor Rear of cab access and standard side of cab access Vacuum, cab clean-out Operator Footrest Deluxe Diffuser Air conditioner Auxiliary power connection/cigarette lighter Diagnostic connection port Dome courtesy light Entertainment Radio Ready: 5 amp converter Speakers Antenna wiring Gauges/indicators: Air cleaner service indicator Quad gauge panel · Air pressure · Brake oil temperature · Engine coolant temperature · Fuel level Electric hour meter Electric engine control fault indicator Engine idle shutdown Mirrors, right and left Speedometer Tachometer Transmission gear indicator VIMS message center with universal gauge VIMS keypad Heater/defroster (11 070 kCal/43, 930 BTU) Horn Hoist, body control (electric) Integrated object detection system ROPS cab, insulated/sound suppressed Seatbelt, operator, 75 mm/3" wide Seatbelt, trainer, two points Stairway and walkway access, 600 mm (24 in) Steering wheel, tilt, padded, telescopic Window, operator, electric powered Windshield wiper, intermittent control and washer FLUIDS Extended Life Coolant to 35° C (30° F) OTHER STANDARD EQUIPMENT Air line dryer Auto lubrication system Auxiliary "buddy" dumping quick connect Auxiliary steering quick connect (towing) Body mounting group Center mounted rims (6) (29×57) (used for 37. 00 R57 tires) Driveline guard (fully enclosed) Fast fill fuel system Ground level VIMS data port Ground level battery disconnect Rock ejectors Supplemental steering (automatic) Tie off points Tow hooks (front) Tow pin (rear) Traction Control System Vital Information Management System

23

789D Optional Equipment

Optional equipment may vary. Consult your Cat dealer for details.

BODY Dual slope body: Body, dual slope, 109 m3 (142 yd3) Dual slope body attachments: Extensions, 457 mm (18"), side, DS,

123 m3 (161 yd3)

Extension, wraparound tail, DS Liner, entire body, DS Liner, wraparound, DS, 450 BHN Rock deflector, rear tire, DS X body: Body, X, 123 m3 (161 yd3) X body attachments: Extensions, side, X, 185 mm (7"),

131 m3 (171 yd3)

Extensions, side, X, 385 mm (15"), 138 m3 (181 yd3) MSD II body: Body, MSD II, 130 m3 (170 yd3) MSD II body attachments: Extensions, side, MSD II,

141 m3 (185 yd3)

Extensions, side, MSD II, 153 m3 (200 yd3) Combination body: Body, combi, 153 m3 (200 yd3) Combination body attachments: Extensions, side, combi, 195 m3 (255 yd3) Gateless coal body: Body, gateless coal, 191 m3 (250 yd3) Gateless coal body attachments: Extensions, side, coal, 214 m3 (280 yd3) Extensions, side, coal, 237 m3 (310 yd3) Body lighting group rear: Directional signals (LED) Stop/tail lights (LED) ELECTRICAL Lockout transmission, ground level Auxiliary work lights (1) RH side, (1) LH side POWER TRAIN Prelube, engine Oil renewal system FILTRATION CONFIGURATIONS Rear axle, cooler OTHER ATTACHMENTS Information management: Control, road analysis (RAC) Cold weather: Brake oil, recirculating Cold weather start Service center: Service, 3516B, standard volume Service, 3516B, large volume Service, 3516C, standard volume Service, 3516C, large volume Service, engine oil, standard Miscellaneous: Fire extinguisher, portable Hub odometer, kilometers Wheel chocks Gauge, brake wear indicator ANTIFREEZE Coolant, 50° C (58° F)

24

Notes

25

Notes

26

27

789D Mining Truck

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at www. cat. com © 2011 Caterpillar Inc. [. . . ]