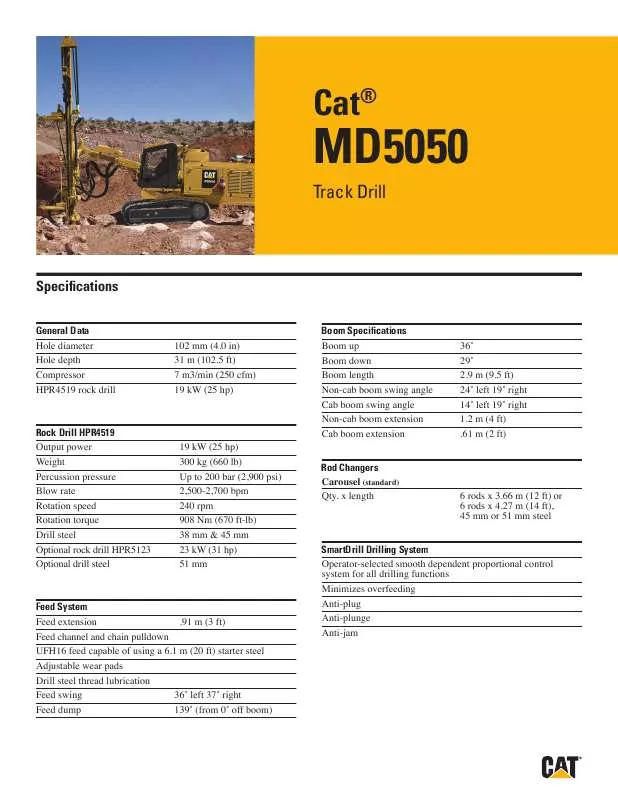

User manual CATERPILLAR MD5050 BROCHURE

Lastmanuals offers a socially driven service of sharing, storing and searching manuals related to use of hardware and software : user guide, owner's manual, quick start guide, technical datasheets... DON'T FORGET : ALWAYS READ THE USER GUIDE BEFORE BUYING !!!

If this document matches the user guide, instructions manual or user manual, feature sets, schematics you are looking for, download it now. Lastmanuals provides you a fast and easy access to the user manual CATERPILLAR MD5050. We hope that this CATERPILLAR MD5050 user guide will be useful to you.

Lastmanuals help download the user guide CATERPILLAR MD5050.

Manual abstract: user guide CATERPILLAR MD5050BROCHURE

Detailed instructions for use are in the User's Guide.

[. . . ] Automatic"On-the-go"regenerationisinitiatedwhenthe enginecontrolmoduledeterminesconditionsareacceptable. Thearticulatedtruckisnotrequiredtostopworking. Automatic:LowIdleregenerationisinitiatedwhenthe machineisinareducedoperatingmodeforapredetermined periodoftime, andanumberofconditionsaremet. [. . . ] Automatic:LowIdleregenerationisinitiatedwhenthe machineisinareducedoperatingmodeforapredetermined periodoftime, andanumberofconditionsaremet. The systemisdesignedso thattheoperatorcaninterrupt regenerationatanytime. Manual:Amanualregenerationisinitiatedbypressing the regenerationswitchfor5seconds. Themachinemust be broughttoanon-operatingmodeinordertoperform a manualregeneration.

3

Transmission

Proven

Reliability.

Electronic

Transmission

TheCatseven-speedforwardandtwo-speedreverseElectronicClutchPressureControlled(ECPC) transmissionfeaturesenhancedshiftcontrollogicwithanti-huntshiftstrategyforspeedcontinuity, and toensureconstantshifttimes.

Min-max

Governor

Control

ECPCcontrolismatchedtothemin-maxgovernorcontrolforprecisesmoothshifting.

Two

Reverse

Gears

Thetransmissionarrangementprovidesasecondreversegearforimprovedperformancewhen operatinginlongerrearhaulingapplications.

Smooth

Transmission

Gear

Shifting

Shift

Torque

Management

(STM)

TheMD5050featuresECPCShiftTorqueManagement(STM), with improvedShiftControlLogic(SCL) andPartThrottleShifting(PTS). Thesefeaturesallowsmoothershiftingandgreateraccelerationon gradeswhiletorqueismaintainedthroughouttheshift changes. SCLalsoprovidesautomaticshift selectionthatismorespecifictothedesiredmachineoperation, anddownshiftswhenneededfor maximumaccelerationwhenincreasedthrottleisapplied. PTSallowsshiftingatlowerspeedsduring partthrottleoperation, resultinginimprovedfueleconomy, quietermachineoperation, andbetter maneuveringinreducedspeedoperatingconditions.

4

Suspension

and

Automatic Traction Control

(ATC)

Performance

and

Productivity.

Front

Suspension

Thethree-pointfrontsuspensionoscillates±6°toprovide asmoothride, allowingtheoperatortotravelatspeedover roughterrainandsofteningimpactloadsonstructuresand components. Largebore, lowpressurecylindersarepurpose designedfortoughapplicationsandofferasoft, smoothride.

Rear

Suspension

FeaturesawalkingbeamgeometrywithCaterpillardesigned rearsuspensionmountswhichprovideareliableandstable rideforexcellentloadretention.

Automatic

Traction

Control

FullyAutomaticTractionControl(ATC). Inter-AxleDifferentiallock(IAD)andCross-Axle-Differentiallocks (XAD)featureoilimmersedclutchesthatrequirenooperator input. Operationisseamlessandsmooth, anditeliminates wheelslipformaximumtraction. Sensorsmonitorthemachineandwheelspeeds, enabling instantresponseinlowtractionconditions. Fullyautomatic, independent, IADandXAD clutchesare engagedon-the-gotooptimizemachineperformanceand controlinallconditions. Clutchesareautomatically disengagedwhengroundconditionsdictate, maximizing efficiencywhensteeringoronunevenground. ATCeliminateswheelspininsoftunderfootextremeground conditionswherelittletractionisavailable. Italsoreduces tireanddrivelineabuseeliminatinglostefficiencycaused by impropermanualoperationofthedifferentialclutches.

Retardation

Control

TheCatenginecompressionbrakecontrolleverispositioned ontheright-handsideofthesteercolumn. Fourmodesofoperationwiththreestepsofretardation, provideanoptimummatchbetweenoperatingconditions andretardingpower.

5

Operator

Comfort

High

productivity

from

a

comfortable,

confident

operator.

Ride

Comfort

Thethree-pointfrontsuspensionwithitsoscillatingaxleandlow-pressureridestruts, combinedwith thecenter-mountedcab, offersunrivaledlevelsofridecomfortfortheoperatorinalldrivingconditions. TheMD5050ismanufacturedtoberebuiltandremanufacturedtoreducewasteandreplacementcosts. TheMD5050isanefficient, productivemachinethatisdesignedtoconserveournaturalresourcesfor generationsahead.

13

MD5050

Articulated

Truck

Specifications

Engine

EngineModel GrossPower SAE J1995 NetPower SAE J1349 NetPower ISO 14396 Bore Stroke Displacement Cat®C15ACERTTM 337kW 452hp 326kW 333kW 437hp 447hp

Transmission

Forward1 Forward2 Forward3 Forward4 Forward5 Forward6 Forward7 Reverse1 Reverse2 8. 3km/h 11. 3km/h 15. 3km/h 20. 6km/h 27. 3km/h 37. 7km/h 51. 1km/h 8km/h 10. 8km/h 5. 1mph 7mph 9. 5mph 12. 8mph 17mph 23. 4mph 31. 8mph 5mph 6. 7mph

Body

Plate

Thickness

Front Scow Side Base 8mm 16mm 12mm 16mm 0. 31in 0. 63in 0. 47in 0. 63in

Service

Refill

Capacities

FuelTank CoolingSystem HydraulicSystem EngineCrankcase Transmission FinalDrives/ Differential OutputTransfer GearBox 560L 80L 328L 38L 72L 72L 18L 148gal 21. 1gal 86. 6gal 9. 5gal 19gal 19gal 4. 8gal

137mm 5. 4in 171. 5mm 6. 75in 15. 2L 926in3

·Thepowerratingsapplyatratedspeedof 1, 700rpmwhentestedundertheconditions forthespecifiedstandard. ·Thenetpoweradvertisedisthepower availableattheflywheelwhentheengine isequippedwithalternator, aircleaner, mufflerandfanatminimumspeed. ·Netpowerwhenthefanisatmaximum speedis300kW(402hp)perthe SAE referenceconditions. ·TheMD5050meetsEPATier4Interim/ EU StageIIIBemissionspecifications for theU. S. andEuropethrough2013 ·Noenginederatingrequiredbelow3800 m (12, 500ft). ·Peakenginetorquegross(SAEJ1995) 2320 N-m(1, 711lb-ft) ·Peakenginetorquenet(SAEJ1349) 2276 N-m(1, 679lb-ft) ·Peakenginetorquespeed(1, 200rpm)

Sound

Levels

InteriorCab 79dB(A)

·TheoperatorsoundexposureLeq (equivalentsoundpressurelevel)measured accordingtotheworkcycleprocedures specifiedinANSI/SAEJ1166OCT98is 79 dB(A), forthecabofferedbyCaterpillar, Body

Hoist

whenproperlyinstalledandmaintainedand Raisetime testedwiththedoorsandwindowsclosed. Lowertime ·Hearingprotectionmaybeneededwhen operatingwithanopenoperatorstation andcab(whennotproperlymaintainedor Standards

doors/windowsopen)forextendedperiods Brakes orinnoisyenvironments. [. . . ] ·Peakenginetorquegross(SAEJ1995) 2320 N-m(1, 711lb-ft) ·Peakenginetorquenet(SAEJ1349) 2276 N-m(1, 679lb-ft) ·Peakenginetorquespeed(1, 200rpm)

Sound

Levels

InteriorCab 79dB(A)

·TheoperatorsoundexposureLeq (equivalentsoundpressurelevel)measured accordingtotheworkcycleprocedures specifiedinANSI/SAEJ1166OCT98is 79 dB(A), forthecabofferedbyCaterpillar, Body

Hoist

whenproperlyinstalledandmaintainedand Raisetime testedwiththedoorsandwindowsclosed. Lowertime ·Hearingprotectionmaybeneededwhen operatingwithanopenoperatorstation andcab(whennotproperlymaintainedor Standards

doors/windowsopen)forextendedperiods Brakes orinnoisyenvironments. Cab/FOPS

11Seconds 7Seconds

Operating

Weights

Weights

RatedPayload 32. 7tonnes 36tons

Body

Capacities

HeapedSAE2:1 Struck TailgateHeaped SAE2:1 TailgateStruck 19. 7m3 14. 7m3 20. 9m3 15. 2m

3

25. 8yd3 19. 2yd3 27. 3yd3 19. 9yd

3

FrontAxleEmpty CenterAxleEmpty RearAxleEmpty TotalEmpty FrontAxle Rated Load CenterAxle Rated Load RearAxle Rated Load TotalRatedLoad FrontAxleLoaded CenterAxle Loaded RearAxleLoaded TotalLoaded

20085kg 6559kg 5829kg 32473kg 3371kg

44, 280lb 14, 460lb 12, 851lb 71, 591lb 7, 432lb

Cab/ROPS Steering

ISO34501996 ISO3449 LevelII2005 ISO34712008 ISO50102007

14664kg 32, 329lb 14664kg 32, 329lb 32700kg 72, 091lb 23456kg 51, 712lb 21223kg 46, 789lb 20494kg 45, 182lb 65173kg 143, 682lb

14

D

imensions

14

4

5

1

70°

15

16

12

13

2

6

3

7 8

9 11

10

17

18

19

mm

6809 2982 635 6088 5467 534 1458 1966 4246 3330 ft

22. 3 9. 8 2. 0 20. 0 17. 9 1. 7 4. 7 6. 4 13. 9 10. 9 mm

11000 3702 3996 4160 3690 3328 2687 3366 3441 ft

36. 1 12. 1 13. 1 13. 6 12. 1 10. 9 8. 8 11. 0 11. 3

1

2

3

4

5*

6

7

8

9

10

11

12

13**

14

15***

16

17

18

19****

*Inside

of

body.

**

xhaust

stack

can

be

removed

for

transportation.

E ***

f

equipped

with

a

scissor

tailgate.

I ****

ax-unladen

over

tire

bulge.

M

15

MD5050

Articulated

Truck

Specifications

T

urning

Circle

Dimensionsareformachinesequippedwith26. 5R25tires. [. . . ]

DISCLAIMER TO DOWNLOAD THE USER GUIDE CATERPILLAR MD5050 Lastmanuals offers a socially driven service of sharing, storing and searching manuals related to use of hardware and software : user guide, owner's manual, quick start guide, technical datasheets...manual CATERPILLAR MD5050