Detailed instructions for use are in the User's Guide.

[. . . ] Operating Instructions

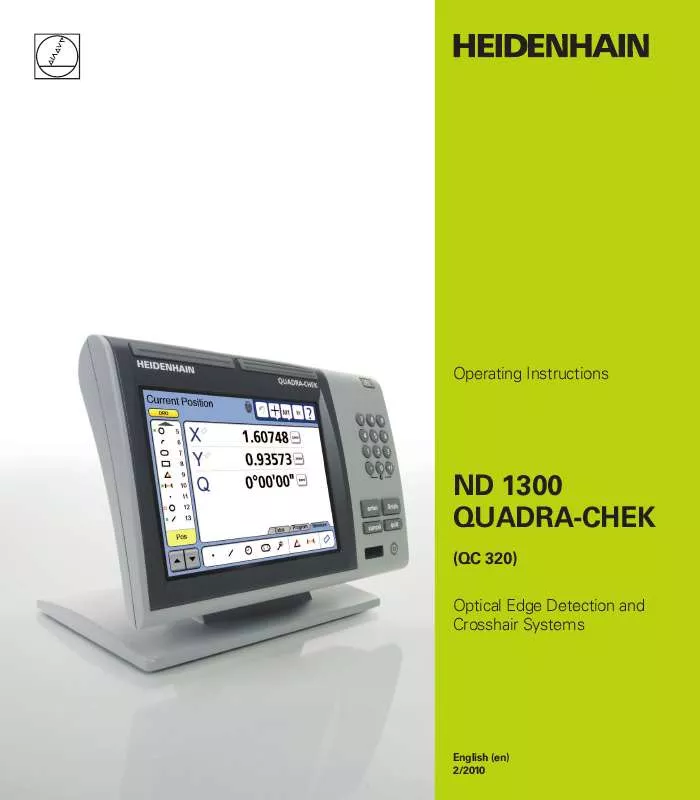

ND 1300 QUADRA-CHEK

(QC 320) Optical Edge Detection and Crosshair Systems

English (en) 2/2010

QC-300 Series User's Guide

Optical Edge Detection Systems QC-320, QC-321, QC-323, QC-324 QC-320E, QC-321E, QC-323E, QC-324E

QC-300 Series Optical Edge Detection and Crosshair Systems User's Guide

Publishedby Metronics, Inc. 30HarveyRoad Bedford, NewHampshire03110 www. Metronics. com User'sGuidepartnumber: 11A10569Revision2 Publishingdate: December, 2007 PrintedinUnitedStatesofAmerica Copyright©2007byMetronics, Inc. , Bedford, NewHampshire QC-300softwareversion: 2. 00 Allinformationsetforthinthisdocument, allrightstosuchinformation, anyandallinventionsdisclosed hereinandanypatentsthatmightbegrantedbyemployingthematerials, methods, techniquesorapparatus describedhereinaretheexclusivepropertyofMetronicsInc. , Bedford, NewHampshire. Terms, conditionsandfeaturesreferencedinthisdocumentaresubjecttochangewithoutnotice. Nopartofthisdocumentmaybereproduced, storedinaretrievalsystem, ortransmittedinanyformorby anymeans, electronic, mechanical, photocopying, recording, orotherwise, withoutpriorwrittenpermissionofMetronics, Inc. . RequeststoMetronics, Inc. forpermissionshouldbeaddressedtotheTechnical ServicesDepartment, Metronics, Inc. , 30HarveyRoad, Bedford, NewHampshire03110.

While this guide was prepared with great care, Metronics makes no representations or warranties with respecttotheaccuracyorcompletenessofthecontentsofthisbookandspecificallydisclaimsanyimplied warrantiesofmerchantabilityorfitnessforaparticularpurpose. Theadvice, methodsandinstructions containedinthisbookmightnotbesuitableforyoursituation. Whenindoubtregardingsuitability, you areencouragedtoconsultwithaprofessionalwhereappropriate. Metronicsshallnotbeliableforanyloss ofprofitoranydamages, includingbutnotlimitedtospecial, incidental, consequentialorotherdamages.

Limit of liability and disclaimer of warranty

Trademarks

MetronicsandQC-300areregisteredtrademarksofMetronics, Inc. anditssubsidiariesintheUnitedStates andothercountries.

Conventions & Terms

QC-300 refers to any of the QC-300 series of instruments. [. . . ] In this example, after the part skew is performed, a datum zero point is constructed at the intersection points of the X-axis along the bottom of the part (skew axis), and the Y-axis along the left side of the part. To construct the datum zero point: 1 Touch the Measure Magic or theMeasureLineicon.

Establishing a Measurement Reference

2 Probe two or more points well distributed along the left side of the part, and then press the Finish button. The line feature will be added to the Features list.

57

3 Touch the Measure Point icon, and then touch each of the two lines in the feature list to checkmark them.

4

Press the Finish key to complete the point construction.

6 Measuring

5 While the constructed point is selected, touch the Zero buttons of the X and Y axes to define the point's location as the zero datum. Select the View window to see the zero datum at the intersection of the X and Y axes.

58

QC-300 Series User's Guide

Probing and measuring features

Part features are measured by creating a part datum, and then by probing points that define the feature's shape and location. Feature points can be probed using Measure Magic or by using a specific measurement function such as the line or circle function. Measurement functions or measure magic are selected by touching a measure icon in the measure toolbar. Measurement results are shown in the Feature list, DRO window and View window.

Measure points

Measure lines

Measure circles & arcs

Measure slots & rectangles Measure Magic

Measure angles

Measure distances

Perform level & skew

The measure toolbar contains icons for measurement functions and measure magic

Probing with Measure Magic

Measure Magic analyzes feature data collected by part probing and automatically determines the feature type. Measure Magic supports the following feature types in the QC-300: · Points · Lines · Circles · Arcs · Slots When Measure Magic is used, and more than the minimum number of points required to define a feature type are collected, the feature type can be changed manually by the user if the wrong feature type is assigned. To probe a feature using measure magic, touch the measure magic measure icon, probe points on the desired feature and then press the Finish key.

Probing and Measuring Features Probing specific feature types

When measure magic is not used a measure icon must be touched before each specific feature type is probed. However, a series of features of the same type can be probed by touching the desired measure icon and then touching multiple measurement icon. Probing a single specific feature type To probe a single feature of a specific type, touch the desired measure icon, probe points on the feature and then press the Finish key. A measure icon must be touched again to measure the next feature. In this example the circle icon is touched to measure a single circle. When a specific measure function is used to probe the feature, the feature type cannot be changed once it is added to the feature list. Probing multiple specific feature types To probe a series of features of a specific type, touch the desired measure icon, touch the multiple measurement icon, probe points on each feature pressing the Finish key to conclude each feature measurement. In this example icons are touched to probe multiple circles.

59

6 Measuring

Touch the circle icon for circle measurements. . .

and then touch the multiple measurement icon to measure a series of circle features

When a specific measure function is used to probe a series of similar features, the feature type cannot be changed once features have been added to the feature list.

60

Probing process

QC-300 Series User's Guide

The feature probing process is essentially the same for all feature types.

Touch the desired measure icon

Probe and enter features, then press Finish to complete measurements

Results are displayed in the DRO and View windows

Supported feature types The following feature measurements are supported by the QC-300: · · · · Points Lines Arcs Circles · · · · Slots Rectangles Distances Angles

Features can be probed manually or semi-automatically as part of a program. NOTE Manual probing is discussed in Chapter 5: Probes. Semi-automatic probing is discussed in Chapter 8: Programming.

Probing and Measuring Features

Backward/forward annotation Forward annotation is used to specify a required number of probed points for each feature type. Backward annotation allows the user to probe any number of points beyond the minimum requirement for any feature type. When using forward annotation, the number of remaining required points is shown at the top left of the screen. As points are probed this number counts down. Backward annotation simply displays the number of points as they are entered. [. . . ] Connect the power cord or turn the power ON. Replace the fuse.

1 PresstheLCDON/OFFbuttontotoggletheLCDON.

Probable cause 2: LCD ON/OFF toggle switch is in the OFF mode Possible solution: Probable cause 3: LCD contrast or backlighting is out of adjustment Possible solution:

1 Readjustthebacklightingusingthedecimalpointor+/-key. 2 Adjust the brightness level in the Miscellaneous setup screen.

Values displayed on the LCD screen are incorrect

Probable cause 1:

1 2

The axis encoder is not connected or is malfunctioning Possible solutions:

Connect the axis encoder cable firmly to the QC-300. Replace the axis encoder.

Probable cause 2:

1

The Encoders setup screen specifies the wrong axis encoder resolution Possible solution:

Specify the correct resolution in the Encoders setup screen.

Probable cause 3:

1

The wrong axis encoder count polarity is specified in the Encoders setup screen Possible solution:

Specify the correct count polarity in the Encoders setup screen.

Symptoms, Probable Causes & Solutions Probable cause 4: The wrong encoder is connected to the axis Possible solutions:

1 2 Connect the axis encoder specified in the Encoders setup screen. [. . . ]

HEIDENHAIN ND 1300 V2.1.0 QUICK REFERENCE GUIDE (2181 ko)

HEIDENHAIN ND 1300 V2.1.0 QUICK REFERENCE GUIDE (2181 ko)