Detailed instructions for use are in the User's Guide.

[. . . ] The proportional pressure controls reduce unnecessary exertion while ensuring precise operation. Large windows allow excellent visibility in all directions.

Low noise design

. The Robex new 7A series is designed with low operation noise in mind. Hyundai engineering made efforts to keep interior and exterior noise levels to a minimum. [. . . ] This decreases fuel consumption and reduces cab noise levels.

2

1

Boom & Arm Holding System

The holding valves in the main control valve prevent the boom & arm from dropping over an extended period in neutral position.

3

Arm Flow Regeneration System

Arm flow regeneration valve provides smooth arm-in operation without cylinder cavitation.

1 POWER MODE

H mode: High power S mode: Standard power

Max. Flow Cut-off System

For precise control and finishing work, the Max. Flow Cut-off System reduces pump flow, thus allowing smooth operation.

2 WORK MODE

: Heavy duty work : General work : Breaker

Hydraulic Damper in Travel Pedal

Improved travel controllability & feeling during movement of the machine by use of shock reducing material.

3 USER MODE

M mode: Maximum Power U mode: Memorizing Operator's Preferable Power Setting

R140W-7A_new_en

11-10-2007

13:54

Pagina 9

Mitsubishi D04FD-TAA Engine

The 4 cylinders turbocharged and charged air cooled, engine is built for power, reliability and economy. This engine meets EPA tier 3 and EUstage 3A emission regulation.

Reliability You Can Depend On

When you have a tough job to do you need the power, precision and flexibility of Mitsubishi D04FD-TAA engines. It features major enhancements to make every piece of equipment work harder, smarter, quieter and longer. The high Pressure Common Rail Fuel System provides enhanced engine performance with higher torque and better throttle response at every rpm without compromising fuel economy. The Mitsubishi D04FD-TAA engine is based on the highly successful Mitsubishi SK series engines. These engines combine proven full authority electronic controls with reliable performance you expect from one of the most successful and durable engine design.

Increased Higher Performance

Reinforced Bucket and Bucket Linkage

To prevent excessive wear of pins and bushes, sealed joints have been applied. Bucket link design incorporates high durability and anti wear characteristics. Additional reinforcement plates on cutting edge section are welded. Thicker steel and an additional lateral plate are put in place to reinforce the bucket.

Strong and Stable Lower Frame

Reinforced box-section frame is all welded, lowstress, high-strength steel. It guarantees safety and resistance against external impact when driving on rough ground and working on wet sites through high tensile strength steel panels, with protection cover for transmission.

Powerful and Precise Swing Control

Improved shock absorbing characteristics make stopping swing movement a precise and smooth action.

Large Toolbox & Safe Footholds

Anti-slip footholds and wide toolbox improved safety and convenience.

HYUNDAI CONSTRUCTION EQUIPMENT 08 /

09

R140W-7A_new_en

11-10-2007

13:54

Pagina 10

Robex 140W-7A

Full open doors and the use of one master key system provide easy access during servicing.

Reliability & Serviceability

Side Cover with Left & Right Swing Open Type

Easy access to vital components gives unrestricted view of components allowing easy maintenance and repair.

Easy to maintain engine components

A cooling and preheating system are provided for optimum and immediate operation, guaranteeing longer life for the engine and hydraulic components. Servicing of the engine and hydraulics is considerably simplified due to total accessibility.

Centralized Electric Control Box and Easy Change Air Cleaner Assembly

Electric control box and air cleaner are centralized in one and the same compartment for easy service.

Highly efficient Hydraulic Pump

Pump output capacity has been increased.

Large tool box for extra storage

R140W-7A_new_en

11-10-2007

13:54

Pagina 11

Durability of structure proven through FEM (Finite Element Method) analysis and long term durability test.

I

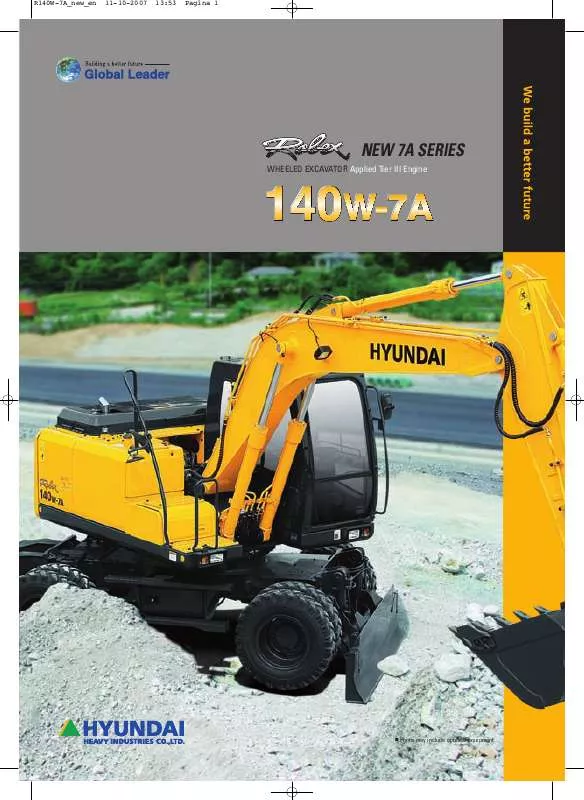

Photo may include optional equipment.

HYUNDAI CONSTRUCTION EQUIPMENT 10 /

11

R140W-7A_new_en

11-10-2007

14:23

Pagina 12

Specifications

Engine

Model Type J1995 (gross) J1349 (net) 6271/1 (gross) DIN 6271/1 (net) Max. torque Bore x stroke Piston Batteries Starting motor Alternator SAE Mitsubishi D04FD-TAA Water cooled, 4 cycle Diesel, 4-Cylinders in line, direct injection, turbocharged, charged air cooled 89 kW (119 HP) at 2, 000 rpm 78 kW (105 HP) at 2, 000 rpm 89 kW (121 PS) at 2, 000 rpm 79 kW (106 PS) at 2, 000 rpm 454 Nm at 1, 700 rpm 102 x 130 mm (4. 01" x 5. 12") 4, 249 cc (259. 3 in3) 2 x 12 V x 100 AH 24 V - 5. 0 kW 24 V - 50 Amp

Axle & Wheel

Full floating front axle is supported by center pin for ocillation. It can be locked by ocillation lock cylinders. Rear axle is fixed on the lower chassis. Tires (optional) 9. 00-20-14PR, Dual (tube type) 9. 00-20, Dual (solid type)

Rated flywheel horse power

Swing System

Swing motor Swing reduction Swing circuit lubrication Swing brake Swing speed Axial piston motor Planetary gear reduction Grease-bathed Multi wet disc (pin lock type) 12. 4 rpm

Steering System Hydraulic system

Main pump Type Two variable displacement piston pumps Max. flow 2x130 l/min (34. 3 US gpm / 28. 6 UK gpm) Sub-pump for pilot circuit Gear pump Cross-sensing and fuel saving pump system Hydraulic motors Travel Two speed axial piston motor with brake valve and parking brake Hydraulically actuated, orbitrol type steering system actuates on front wheels through the steering cylinders. Pilot control Engine throttle External Lights Two joysticks with one safety lever (LH): Swing and arm, (RH): Boom and bucket (ISO) Electric, Dial type Two lights mounted on the boom one under the battery box and one under the cabin.

Operating weight

Undercarriage * Rear dozer blade Rear outrigger front outrigger and rear blade front blade and rear outrigger four outrigger

Standard equipment

Mono boom 13, 500 (29, 760) 13, 900 (30, 640) 14, 500 (31, 970) 14, 500 (31. 970) 14, 900 (32, 850)

Hyd. adjustable boom 13, 900 (30, 640) 14, 300 (3, 1530) 14, 900 (32, 850) 14, 900 (32, 850) 15, 300 (33, 730)

R140W-7A_new_en

11-10-2007

14:23

Pagina 13

Backhoe attachment

Buckets

0. 23 (0. 30) SAE heaped m (yd )

3 3

0. 40 (0. 52) 0. 46 (0. 60)

0. 52 (0. 68) 0. 58 (0. 76)

0. 65 (0. 85)

0. 71 (0. 93)

0. 45 (0. 59)

0. 55 (0. 72)

Capacity m3 (yd3) SAE heaped 0. 23 (0. 30) 0. 40 (0. 52) 0. 46 (0. 60) 0. 52 (0. 68) 0. 58 (0. 76) 0. 65 (0. 85) 0. 71 (0. 93) 0. 45 (0. 59) 0. 55 (0. 72) CECE heaped 0. 20 (0. 26) 0. 35 (0. 46) 0. 40 (0. 52) 0. 45 (0. 59) 0. 50 (0. 65) 0. 55 (0. 72) 0. 60 (0. 78) 0. 40 (0. 52) 0. 45 (0. 59)

Width mm (in) Without side cutters 520 (20. 5) 750 (29. 5) 840 (33. 1) 915 (36. 0) 1, 000 (39. 4) 1, 105 (43. 5) 1, 190 (46. 9) With side cutters 620 (24. 4) 850 (33. 5) 940 (37. 0) 1, 015 (40. 0) 1, 100 (43. 3) 1, 205 (47. 4) 1, 290 (50. 8) -

Weight kg (lb) 335 (740) 410 (900) 435 (960) 460 (1, 010) 480 (1, 060) 500 (1, 100) 540 (1, 190) 410 (900) 585 (1, 290)

Boom Arm 1. 9 (6' 3")

Recommendation mm (ft. in) 4. 9 (16' 1") Hydraulic Adjustable boom 4. 6 (15' 1") 2. 1 2. 5 3. 0 1. 9 2. 1 2. 5 (6' 11") (8' 2") (9' 10") (6' 3") (6' 11") (8' 2")

-

-

-

-

: Standard backhoe bucket : Ditching bucket : Slope finishing bucket

: Applicable for materials with density of 2, 000 kg/m3 (3, 370 lb/yd3) or less : Applicable for materials with density of 1, 600 kg/m3 (2, 700 lb/yd3) or less : Applicable for materials with density of 1, 100 kg/m3 (1, 850 lb/yd3) or less

Backhoe attachment

Boom and arms are of all-welded, low-stress, full-box section design. 4. 6 m (15' 1") mono boom and 4. 9 m (16' 1") adjustable boom and 1. 90 m (6' 3"), 2. 10 m (6' 11"), 2. 50 m (8' 2"), 3. 00 m (9' 10") arms are available. Buckets are all-welded, high-strength steel implements.

1. 9 m (6' 3")

2. 1 m (6' 11")

2. 5 m (8' 2")

3. 00 m (9' 10")

Digging force

Arm Length Weight SAE m(ft. in) kg(lb) kN kgf lbf kN kgf lbf kN kgf lbf kN kgf lbf 1. 90 (6' 3") 560 (1, 230) 83. 4 [91] 8, 500 [9, 270] 18, 740 [20, 440] 96. 1 [104. 8] 9, 800 [10, 690] 21, 610 [23, 570] 74. 5 [81. 3] 7, 600 [8, 290] 16, 760 [18, 280] 78. 5 [85. 6] 8, 000 [8, 730] 17, 640 [19, 240] 2. 10 (6' 11") 580 (1, 280) 83. 4 [91 ] 8, 500 [9, 270] 18, 740 [20, 440] 96. 1 [104. 8 ] 9, 800 [10, 690] 21, 610 [23, 570] 71. 6 [78. 1 ] 7, 300 [7, 960] 16, 090 [17, 550] 75. 5 [82. 4 ] 7, 700 [8, 400] 16, 980 [18, 520]

Standard arm

2. 50 (8' 2") 610 (1, 340) 83. 4 [91] 8, 500 [9, 270] 18, 740 [20, 440] 96. 1 [104. 8] 9, 800 [10, 690] 21, 610 [23, 570] 61. 8 [67. 4] 6, 300 [6, 870] 13, 890 [15, 150] 64. 7 [70. 6] 6, 600 [7, 200] 14, 550 [15, 870]

3. 00 (9' 10") 670 (1, 480) 83. 4 [91] 8, 500 [9, 270] 18, 740 [20, 440] 96. 1 [104. 8] 9, 800 [10, 690] 21, 610 [23, 570] 53. 9 [59. 0] 5, 500 [6, 020] 12, 130 [13, 270] 56. 9 [62. 1] 5, 800 [6, 330] 12, 790 [13, 950] Remark

Bucket digging force

ISO

Arm crowd force

SAE

[ ]: Power Boost

ISO

Note: Arm weight including bucket cylinder and linkage.

HYUNDAI CONSTRUCTION EQUIPMENT 12 /

13

R140W-7A_new_en

11-10-2007

13:54

Pagina 14

Dimensions & Working ranges

Dimensions R140W-7A

140w-7A

mm (ft

in)

Mono Boom Arm A B C D F G Overall length of shipping position Overall length of traveling position Height of attachment(shipping position) Height of attachment(traveling position) Overall witdh Height of cabin 1900 (6' 3") 7740 (25' 5") 7730 (25' 4") 2760 (9' 1") 3500 (11' 6") 2500 (8' 2") 3140 (10' 4")

4600 (15' 1") 2100 (6' 11") 7800 (25' 7") 7740 (25' 5") 2870 (9' 5") 3500 (11' 6") 2500 (8' 2") 3140 (10' 4") 2500 (8' 2") 7750 (25' 5") 7670 (25' 2") 2820 (9' 3") 3620 (11' 11") 2500 (8' 2") 3140 (10' 4") 3000 (9' 10") 7760 (25' 6") 7680 (25' 2") 3340 (10' 11") 3600 (11' 10") 2500 (8' 2") 3140 (10' 4")

Standard Equipment

Working ranges R140W-7A

mm (ft

in)

Boom length Arm length A A' B B'

140w-7A

4600 (15' 1") 1900 (6' 3") 2100 (6' 11") 2500 (8' 2") 3000 (9' 10")

4100 (13' 5") 1900 (6' 3") 2100 (6' 11")

Max. [. . . ] http://ceres. hhi. co. kr

HYUNDAI CONSTRUCTION EQUIPMENT 18 /

19

R140W-7A_new_en

11-10-2007

14:46

Pagina 20

Standard Equipment

ISO standard cab · All-weather steel cab with all-around visibility · Safety glass windows · Rise-up type windshield wiper · Sliding fold-in front window · Sliding side window · Lockable door · Hot & cool box · Accessory box & Ash-tray Computer Aided Power Optimization (New CAPO) system · 2-power mode, 3-work mode, 2-user mode · Auto deceleration & one touch deceleration system · Auto warm up system · Auto overheat prevention system Air-conditioner (5000kcal/hr; 20000BTU/hr) FATC (Full Automatic Temperature Control) Self diagnostic system Centralized monitoring · LCD display Engine speed Clock & Error code · Gauges Fuel level gauge Engine coolant temperature gauge Hyd. oil temperature gauge · Warning Fuel level Check Engine & CPU Engine oil pressure Engine coolant temperature Hyd. oil temperature Low battery Air cleaner clogging · Indicator Power max. Preheat & Engine warming-up One touch decel Door and cab locks, one key Two outside rearview mirrors Fully adjustable suspension seat with seat belt Slidable joystick, pilot-operated Automatic swing brake Removable reservoir tank Water separator, fuel line Boom holding system Arm holding system Counterweight (1, 900 kg; 4, 190 lb) Mono boom (4. 6 m, 15' 1") Arm (2. 1 m; 6' 11") Safety lock valve for boom cylinder with overload warning device Single acting piping kit (breaker, etc) Double acting piping kit (cramshell, etc) AM/FM radio and CD · Radio remote switch Console box tilting system (LH. ) Two front working light Electric horn Batteries (2 x 12 V x 100 AH) Battery master switch Starting Aid (air grid heater) cold weather Standard bucket (0. 58 m3; 0. 76 yd3) Rear - blade (550 x 2500) Tires - dual (9. 00 - 20 - 14PR) Travel alarm Fuel filler pump (36 l/min; 9. 5 USgpm)

Optional Equipment

Heater (7500 kcal/hr; 30000BTU/hr) & Defroster Sun visor for cabin inside Beacon lamp Safety lock valve for arm cylinder Accumulator, work equipment lowering 12 volt power supply (DC-DC converter) Electric. [. . . ]