Detailed instructions for use are in the User's Guide.

[. . . ] New front window mechanism designed with spring assist.

Improved Seat & Console

Ergonomic joysticks equipped with auxiliary buttons for attachment use. Standard mechanic suspension with heater or optional air suspension. New joystick consoles - adjustable in height. Adjustable arm rests - for optimum comfort.

Advanced 7" Color Cluster

New Color LCD Display with digital gauges for hydraulic oil temperature, coolant temperature and fuel level. [. . . ] The Auto boom-swing priority results into faster movements and shorter cycle times.

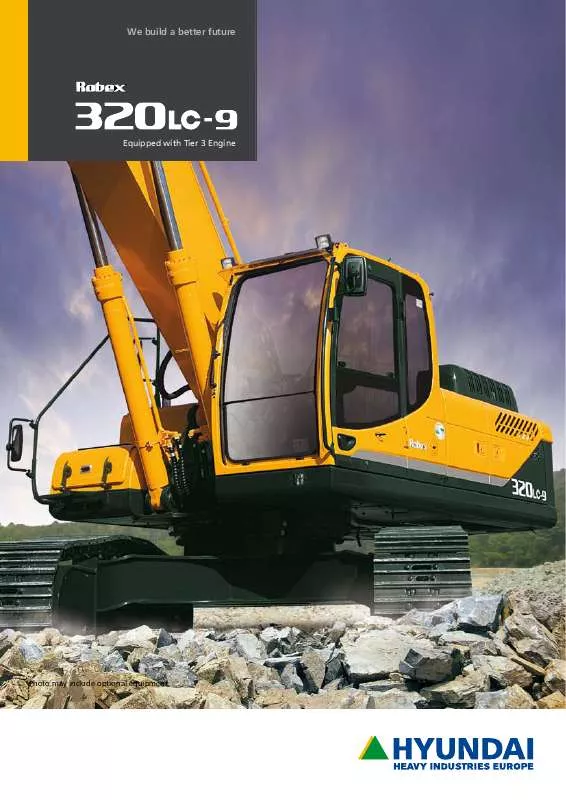

*Photo may include optional equipment.

Track Rail Guard & Adjusters

Durable track rail guards keep tracks in place. Track adjustment is made easy with standard grease cylinder track adjusters and shock absorbing springs.

CUMMINS QSC Engine

The Tier III compliant, six cylinder, turbo-charged, 4 cycle, water cooled, Cummins QSC diesel engine is built for power, reliability, efficiency and reduced emissions.

Heavy-duty strength

The QSC from Cummins. All wrapped up in something we call the Quantum system. The QSC is built to withstand the toughest circumstances. Bearings have more surface area to handle higher loads with greater durability. The exhaust manifold compensates heat expansion and contraction, eliminating metal stress. Reduced friction in the power cylinder means longer life and increased power output. From the reinforced block to the stiffened gear housing, the QSC is built stronger to last longer.

Structural Strength

The 9 series cabin structure is designed with slimmer but stronger tubing for more safety and better visibility. Low-stress and high-strength steel is welded to form a strong and stable lower frame. Structural durability is analyzed and tested by FEM-analysis (Finite Elements Method) and long-term durability tests.

Profitable

An owner, who knows his machine saves money, takes pleasure in owning it. 9 Series excavators contribute to your business as a time, fuel, spare-part and cost saving earthmoving solution. The Remote Management System allows machine owners to track, monitor and manage at a distance.

*Photo may include optional equipment.

Fuel Economy

9 series excavators are developed to do more work with less fuel. Implemented innovations like the variable speed hydraulic driven fan, three-stage auto decel system and the new economy mode, are helping to save fuel and reduce the impact on the environment.

Hi-mate (Remote Management System)

Hi-mate, Hyundai's newly developed remote management system, using GPS-satellite technology, provides our customers with the highest level of service and product support. Hi-mate enables machine owners to follow-up machine performance, to verify machine location and to access diagnostic information on a distance through any internet connection.

Easy Access

Access from ground to filters, lube fittings, fuses, drains and machine computer components, combined with wide open compartments makes servicing the 9-series a pleasure for your mechanics.

Extended Life of Components

New long-life bushings are designed for extended lube intervals. Wearresistant polymer shims reduce noise and reduce wear of bushings. Extended-life hydraulic filters last up to 1, 000 hrs and new long-life hydraulic oil need only be changed every 5, 000 hrs.

Specifications

EngInE

ModEl

Type

SWIng SySTEM

CuMMins QsC

Water cooled, 4 cycle diesel, 6-Cylinders in line, direct injection, turbocharged, charged air cooled and low emission sAE din J1995 (gross) J1349 (net) 6271/1 (gross) 6271/1 (net) 278 HP (213 kW) / 1, 750 rpm 263 HP (196 kW) / 1, 750 rpm 282 Ps (213 kW) / 1, 750 rpm 267 Ps (196 kW) / 1, 750 rpm 123. 7 kgf. m (895 lbf. ft) / 1, 500 rpm 114 mm x 135 mm (4. 5" x 5. 3") 8, 300 cc (506 in3) 2 x 12V x 160AH 24 V, 7. 5 kW 24 V, 50 Amp swing motor swing reduction swing bearing lubrication swing brake swing speed Axial piston motor Planetary gear reduction Grease-bathed Multi wet disc 9. 2 rpm

Rated flywheel horse power Max. torque Bore x stroke

COOlAnT & lUBRICAnT CAPACITy

Refilling fuel tank Engine coolant Engine oil swing device - gear oil final drive (each) - gear oil Hydraulic system (including tank) Hydraulic tank liter 500 45. 0 35 11 5. 5 330 190 us gal 132. 1 11. 9 9. 2 1. 8 2. 9 87. 2 50. 2 uK gal 110. 0 9. 9 7. 7 1. 5 2. 4 72. 6 41. 8

Piston displacement Batteries starting motor Alternator

HydRAUlIC SySTEM

MAin PuMP

Type Max. flow sub-pump for pilot circuit Two variable displacement piston pumps 2 x 270 l /min (68. 7 us gpm/57. 2 uK gpm) Gear pump

UndERCARRIAgE

The X-leg type center frame is integrally welded with reinforced box-section track frames. The undercarriage includes lubricated rollers, idlers, track adjusters with shock absorbing springs and sprockets, and a track chain with double or triple grouser shoes. 6. 45 m and 6. 15 m booms and 2. 2 m; 2. 5 m; 2. 92 m; 3. 2 m & 4. 05 m arms are available.

dIggIng fORCE

Boom Arm length Weight length Weight SAE mm (ft. in) kg (lb) mm (ft. in) kg (lb) kN Bucket digging force kgf lbf kN ISO kgf lbf kN Arm crowd force SAE kgf lbf kN ISO kgf lbf 2, 200 (7' 3") 1, 560 (3, 440) 189. 3 [205. 5] 19, 300 [20, 950] 42, 550 [46, 200] 211. 8 [230. 0] 21, 600 [23, 450] 47, 620 [51, 700] 196. 6 [213. 4] 20, 000 [21, 760] 44, 190 [47, 980] 202. 8 [220. 2] 20, 700 [22, 450] 45, 600 [49, 510] 6, 450 (21' 2") 3, 030 (6, 680) 2, 500 (8' 2") 1, 650 (3, 640) 189. 3 [205. 5] 19, 300 [20, 950] 42, 550 [46, 200] 211. 8 [230. 0] 21, 600 [23, 450] 47, 620 [51, 700] 178. 9 [194. 2] 18, 200 [19, 810] 40, 220 [43, 670] 185. 1 [201. 0] 18, 900 [20, 500] 41, 620 [45, 190] 3, 200 (10' 6") 1, 770 (3, 900) 189. 3 [205. 5] 19, 300 [20, 950] 42, 550 [46, 200] 211. 8 [230. 0] 21, 600 [23, 450] 47, 620 [51, 700] 143. 2 [155. 5] 14, 600 [15, 850] 32, 190 [34, 950] 147. 1 [159. 7] 15, 000 [16, 290] 33, 070 [35, 900] 4, 050 (13' 3") 1, 870 (4, 120) 189. 3 [205. 5] 19, 300 [20, 950] 42, 550 [46, 200] 211. 8 [230. 0] 21, 600 [23, 450] 47, 620 [51, 700] 119. 6 [129. 9] 12, 200 [13, 240] 26, 890 [29, 190] 122. 7 [133. 3] 12, 515 [13, 590] 27, 590 [29, 950] [ ]: Power Boost Remarks

note: Boom weight includes arm cylinder, piping, and pin Arm weight includes bucket cylinder, linkage, and pin

dimensions & Working Ranges

dIMEnSIOnS R320lC-9 / R320nlC-9

D(D') E

J C A B I

mm (ft . in) A Tumbler distance R320LC-9 R320NLC-9 B overall length of crawler C Ground clearance of counterweight D Tail swing radius D' Rear-end length E overall width of upperstructure F overall height of cab G Min. ground clearance H Track gauge R320LC-9 R320NLC-9 4, 030 (13' 3") 4, 030 (13' 3") 4, 940 (16' 2") 1, 200 (3' 11") 3, 330 (10' 11") 3, 265 (10' 9") 2, 980 (9' 9") 3, 090 (10' 2") 500 (1' 8") 2, 680 (8' 10") 2, 390 (7' 10") L overall width R320NLC-9 R320LC-9 J I Arm length overall length overall height of boom Boom length 2, 200 (7' 3") 11, 230 (36' 10") 3, 640 (11' 11") 2, 500 (8' 2")

F G H K L

mm (ft . [. . . ] lifting capacity is based on sAE J1097, iso 10567. lifting capacity of the Robex series does not exceed 75% of the tipping load with the machine on firm, level ground or 87% of full hydraulic capacity.

3. The load point is a hook located on the back of the bucket. (*) indicates the load limited by hydraulic capacity.

STAndARd EQUIPMEnT

iso standard cabin All-weather steel cab with 360° visibility safety glass windows Rise-up type windshield wiper sliding fold-in front window sliding side window one key fits all lockable doors Hot & cool box storage compartment & Ashtray Transparent cabin roof-cover Cd/MP3 Player Handsfree mobile phone system with usB-charging device sun visor Computer aided power optimization (new CAPo) system 3-power modes, 3-work modes, user mode Auto & one-touch deceleration system Auto warm-up system overheat prevention system Automatic temperature control Air conditioner & heater defroster self-diagnostics system starting Aid (air grid heater) for cold weather Centralized monitoring lCd display Engine speed or Trip meter Clock Gauges - fuel level gauge - Engine coolant temperature gauge - Hyd. [. . . ]