Detailed instructions for use are in the User's Guide.

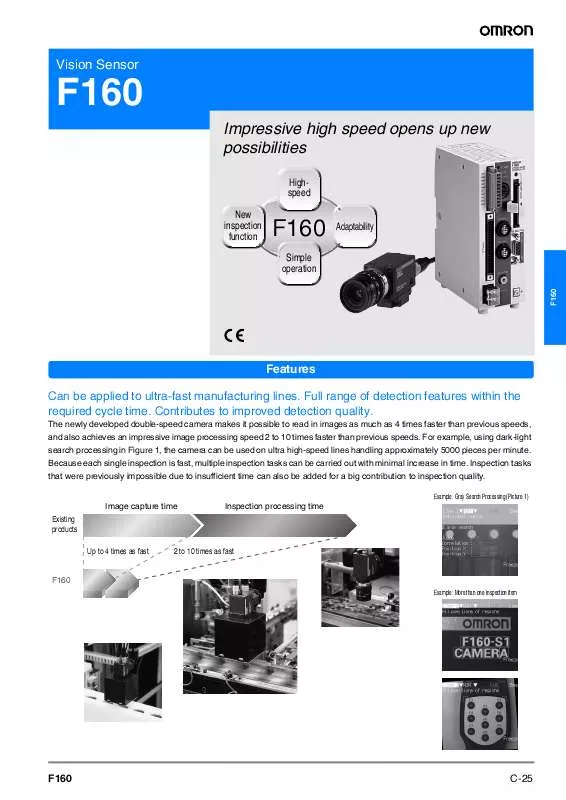

[. . . ] For example, using dark-light search processing in Figure 1, the camera can be used on ultra high-speed lines handling approximately 5000 pieces per minute. Because each single inspection is fast, multiple inspection tasks can be carried out with minimal increase in time. Inspection tasks that were previously impossible due to insufficient time can also be added for a big contribution to inspection quality.

Example: Gray Search Processing (Picture 1)

Image capture time Existing products Up to 4 times as fast F160

Inspection processing time

2 to 10 times as fast

Example: More than one inspection item

F160

C-25

F160

Features Equipped with a memory card for low-cost introduction on multi-type lines and a dramatic increase in the number of scenes. [. . . ] Switch menus at the touch of a key.

Measurement image Line-brightness display

Password function

Operation access can be limited to personnel who have been issued a password. This contributes to increased security.

Switch the display with one touch

Screen

The character size can be selected, and even highlighting is possible.

Screen messages

Change to the language used on-site. Can be displayed in any position on the screen.

X: 135. 644 Y: 215. 957

X: 135. 644 Y: 215. 957

Color display function

Colors can be added to displayed messages and graphics for easier viewing.

Graphic drawing function

This allows you to draw straight lines, rectangles, cross-hair cursors, and other graphics. Graphics can be drawn on measurement positions as well.

Output

Dialog menu

Dialog-type menus allow even beginners an easy performance of settings.

RS-232C format

The output format can be changed to meet the specifications of the system.

F160

C-27

F160

Features QUEST Character Recognition

F160 uses OMRON's character recognition system - QUEST.

Features · The user does not have to register characters. · High discrimination level of similar characters. · Adapts to fluctuations in shape and size.

Use for any type of character

Rotation search

This function rotates the image while searching. Processing speed is 10 times higher than previous models. Angle interpolation enables high-precision angle detection.

Example: Searching in a rotation range of 360° with a skipping angle of 5°.

Classification

A search is performed using multiple stored models, and the best-matching model number is output. The flexible search function can also be used for work shapes. Can handle variations in shape.

1

L M S

"Variable Box" Measurement for Defect Inspection

The measurement area can be set to change automatically when performing inspections for objects with varying sizes, such as electronic chip components. This feature ensures that the optimum measurement areas are always used for inspection.

Setting screen Measurement screen

2 3

L

Model1

M

Model2

S

Model3

Edge width

The positions of both edges of an object are detected with high accuracy, and from this the width of the object is calculated. It is not necessary to set expressions for calculating the width.

Set frames for adjusting the region size

The inspection region automatically adapts to the object size.

Flexible Search

This method performs a matching using more than one reference image and so F160 can perform inspection for objects with varying shapes. This feature helps to reduce incorrect evaluations.

Position displacement compensation

F160 permits compensation using only the outline of the object, 2-stage position compensation, and setting priorities for the compensation direction.

Compensation in the X direction followed by compensation in the Y direction.

Labeling

The number of labels (i. e. , objects) inside the measurement area is counted. After they have been sorted according to area or center of gravity, the measurement data for specified labels is output.

Counting gears

Inspecting the position and number of buttons

Expressions

Evaluation and data output based on a maximum of 32 expressions is possible. Up to 32 variables (representing other expressions) can be used, enabling more complex calculations.

Matching can be performed for products with varying shapes by using more than one reference image.

C-28

Vision Systems

Ordering information

Name Controller Controller Camera with intelligent lighting Camera only F160-S2 Camera with intelligent lighting Compatible F150 cameras Camera with light F150-SL50A Camera only Console Color LCD monitor Monochrome CRT Video monitor Memory card Camera cable Monitor cable Parallel cable

*1.

Model F160-C10E-2 F160-C15E-2 F160-SLC20 F160-SLC50 F160-S1

Remarks NPN Input/Output PNP Input/Output

Double-speed camera

With partial scan function.

F150-SLC20 F150-SLC50 F150-SL20A

F150-S1A F160-KP

F160

F150-KP F150-M05L F150-M09 F160-N64S(S) F150-VS F150-VM F160-VP Memory capacity 64 MB For Double-speed Camera and compatible F150 Cameras. Cable length: 3 m*1 Cable length: 2 m*1 Loose-wire cable for parallel I/O connectors. Cable length: 2 m

Other length on request

F160

C-29

Rating/Performance

Controller: F160-C10E-2/F160-C15E-2

Item Specifications Connectable cameras Number of cameras connectable Number of pixels Number of scenes Image storage function Filtering Conversational Menu Mode Expert Menu Mode F150-S1A/SL20A/SL50A/SLC20/SLC50, F160-S1/S2/SLC20/SLC50, etc. 1 2

Position displacement compensation Number of measurement regions Applications

512 x 484 (H x V) 32 scenes (Expansion possible using Memory Card) Maximum of 35 images stored Smoothing (strong/weak), edge enhancement, edge extraction (horizontal, vertical, both horizontal and --vertical), dilation, erosion, median, background suppression Set either automatically or manually Compensation directions: X, Y, and (360°)directions Compensation directions: X, Y, and (360°) Detection methods: Binary center of gravity, axis angle, labeling, rotation directions search, gray search, edge position 32 regions per scene 7 types available (presence, orientation, dimensions, defects, conformity, position, chips and burs Automatically selected according to the application --Gravity and area, gravity and axis, gray search, precise search, rotation search, flexible search, relative search, defect, area (variable box), defect (variable box), edge position, edge pitch, edge width, density average, labeling, OCR for 1 character, classification Number: 32 expressions can be set for judgements, data, and variables used in other expressions. [. . . ] 2000

CONSOLE

87

1/4-20UNC with depth of 8 mm 20±0. 1 (13. 25)

23

5

10

F160-SLC20 (with F150-LTC20 intelligent lighting)

2. 5 70 12 12 73 46. 5 (85) (10) 70 4 dia. 25

LCD monitor F150-M05L

Mounting plate thickness: 1. 6 to 4. 8 (46 max. ) Mounting bracket

POWER

143

SYNC

42. 5

132

(145) (155)

2. 5

12

31 40

12 (96. 25)

30. 5 (23. 25)

8

(100) 185 42. 2

(5. 5) Monitor cable (F150-VM)

1/4-20UNC with depth of 10 mm 174 Panel cut figure Two M4 mounting holes with depth of 10 mm (86. 25) 20±0. 3 (13. 25)

Tolerance:±1 mm The dimensions in parentheses are reference values.

F160-SLC50 (with F150-LTC50 intelligent lighting)

2. 5

90 16 16

80

46. 5

(85)

175. 5+0. 5mm 0

(10)

90 4 dia.

25

Video monitor F150-M09

222 250

16

31 60

16 (103. 25)

2. 5

52. 5

30. 5 (23. 25)

8

233

1/4-20UNC with depth of 10 mm

Two M4 mounting holes with depth of 10 mm

143

190

50 22

50min

133. 5 +0. 5mm 0

160

(13. 25) (93. 25) 20±0. 3

F160

5

C-35

12. 5

F160

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS. To convert millimeters into inches, multiply by 0. 03937. [. . . ]

OMRON F160 BROCHURE (530 ko)

OMRON F160 BROCHURE (530 ko)