Detailed instructions for use are in the User's Guide.

[. . . ] Thermal Overload Relay

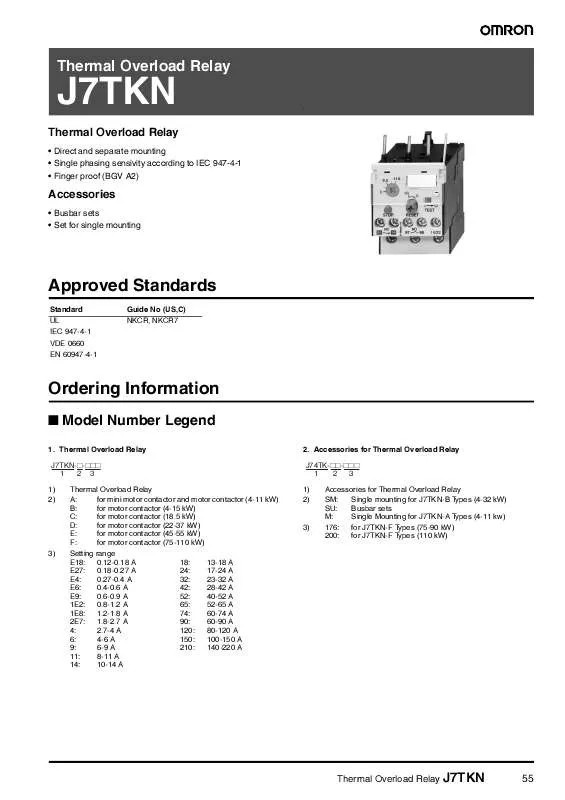

J7TKN

Thermal Overload Relay

· Direct and separate mounting · Single phasing sensivity according to IEC 947-4-1 · Finger proof (BGV A2)

)

Accessories

· Busbar sets · Set for single mounting

Approved Standards

Standard UL IEC 947-4-1 VDE 0660 EN 60947-4-1 Guide No (US, C) NKCR, NKCR7

Ordering Information

Model Number Legend

1. Accessories for Thermal Overload Relay

J7TKN-#-### 1 23

1) 2) Thermal Overload Relay A: for mini motor contactor and motor contactor (4-11 kW) B: for motor contactor (4-15 kW) C: for motor contactor (18. 5 kW) D: for motor contactor (22-37 kW) E: for motor contactor (45-55 kW) F: for motor contactor (75-110 kW) Setting range 18: 13-18 A E18: 0. 12-0. 18 A 24: 17-24 A E27: 0. 18-0. 27 A 32: 23-32 A E4: 0. 27-0. 4 A 42: 28-42 A E6: 0. 4-0. 6 A 52: 40-52 A E9: 0. 6-0. 9 A 65: 52-65 A 1E2: 0. 8-1. 2 A 74: 60-74 A 1E8: 1. 2-1. 8 A 90: 60-90 A 2E7: 1. 8-2. 7 A 120: 80-120 A 4: 2. 7-4 A 150: 100-150 A 6: 4-6 A 210: 140-220 A 9: 6-9 A 11: 8-11 A 14: 10-14 A

J74TK-##-### 1 2 3

1) 2) Accessories for Thermal Overload Relay SM: Single mounting for J7TKN-B Types (4-32 kW) SU: Busbar sets M: Single Mounting for J7TKN-A Types (4-11 kw) 176: for J7TKN-F Types (75-90 kW) 200: for J7TKN-F Types (110 kW)

3)

3)

Thermal Overload Relay

J7TKN

55

System overview

Thermal Overload Relays for plug-in mounting

Setting Range D. O. L. Weight kg/pc.

For contactors J7KNA-09. . . , J7KNA-12. . . [. . . ] 0, 12 0, 18 0, 27 0, 4 0, 6 0, 8 1, 2 1, 8 2, 7 4 6 8 10

A

3

4

5

6

7, 2

8

When selecting a standard overload, refer to the tripping curve. Determine the values of the starting current ratio IA/IN and the time tE which is marked on the label of the motor. The overload must trip within the tE time, which means that the tripping curve from cold condition must be (20% due to tolerance) below the coordination point IA/ IN and the time tE. IA= Starting current of motor IN = Rated current of motor

- 0, 18 - 0, 27 - 0, 4 - 0, 6 - 0, 9 - 1, 2 - 1, 8 - 2, 7 -4 -6 -9 - 11 - 14

18, 5 16, 7 19, 4 18, 7 19, 7 22, 9 22, 2 23 24 24, 7 22 17, 4 26, 4

10, 4 9, 8 12, 1 11, 2 11, 6 13, 6 13, 2 13, 7 14, 4 13, 8 13, 4 9, 2 12, 9

7, 2 6, 5 8, 2 8 8, 1 10 9, 2 9, 3 9, 9 9, 9 8 5, 9 7, 6

5, 5 5 5, 9 6 6, 1 7, 3 7, 6 7, 6 7, 8 7, 3 5, 7 4, 1 5, 2

4, 3 4, 1 4, 9 4, 9 4, 9 6 5, 8 5, 7 5, 9 5, 6 4, 1 2, 9 3, 5

3, 6 3, 5 4, 2 4, 1 4, 2 5, 2 5, 3 5, 1 5, 1 4, 8 3, 5 2, 3 2, 8

tE = tE-time of motor All tripping times of overload relays J7TKN-A are shorter than the minimum values of the tE time for motors of protection degree EEx e acc. to EN 50019 and therefore are suitable for all motors of protection degree EEx e. For these overload relays the selection on basis of tripping curves is thereby not necessary.

Typical tripping curve for overload relay J7TKN-A

Minimum values of tE time (motor) acc. 0, 12 0, 18 0, 27 0, 4 0, 6 0, 8 1, 2 1, 8 2, 7 4 6 8 10 13 17 23 - 0, 18 - 0, 27 - 0, 4 - 0, 6 - 0, 9 - 1, 2 - 1, 8 - 2, 7 -4 -6 -9 - 11 - 14 - 18 - 24 - 32 16, 1 16, 6 19, 4 18, 7 19, 2 20, 8 25, 5 26, 6 22, 7 22, 2 20, 4 20, 9 21, 3 21, 2 20, 4 20, 2 9, 6 9, 7 11, 4 10, 9 11, 2 12, 3 14, 1 15, 6 13, 6 13, 3 11, 9 11, 8 11, 7 12, 1 12 10, 2 6, 8 6, 7 7, 9 7, 6 7, 7 8, 5 9, 8 10, 9 9, 5 9, 3 8, 2 7, 9 7, 4 8, 0 8, 6 6, 7 5, 3 5, 2 6, 1 5, 9 5, 9 6, 6 7, 6 8, 3 7, 4 7, 1 6, 1 5, 7 5, 1 6, 2 6, 3 4, 7 4, 2 4, 1 4, 7 4, 6 4, 6 5, 2 5, 9 6, 5 5, 8 5, 6 4, 7 4, 3 3, 7 4, 6 4, 5 3, 4 3, 7 3, 6 4, 2 4, 0 4, 1 4, 6 5, 2 5, 7 5, 1 4, 9 4, 0 3, 5 3, 0 4, 1 3, 7 2, 8 Labels of tripping curves for each setting range, sized 148x105mm (self-adhesive) are available on request. Specify type and setting range.

ratio IA/IN

J7TKN-C-42 28 - 42 25, 2 13, 3 8 5, 5 4 3, 1

J7TKN-D-. . . 40 52 60 - 52 - 65 - 74 18, 3 17, 8 19, 5 9, 2 8, 7 13, 5 5, 6 5, 2 11 3, 9 3, 4 10 2, 8 2, 5 9, 5 2, 2 1, 9 8, 5

J7TKN-E-. . . 60 80 - 90 - 120 19, 5 18 s 34 30 13, 5 11 s 26 24 11 10 s 24 21 10 9 s 20, 5 18, 5 9, 5 8, 5 s 19 17 8, 5 8 s 18 16

J7TKN-F-. . . 100 140 - 150 - 210

58

Thermal Overload Relay J7TKN

Fuses for J7TKN-A; J7TKN-B; J7TKN-C; J7TKN-D; J7TKN-E; J7TKN-F

Type Setting Range Max. Fuse Size According to Coordination- Fuse UL type Star Delta A A "2"*1 quick slow, gL(gG) "1"*1 slow, gL(gG) aM A 15 15 15 15 15 15 15 15 15 15 25 30 40 50 60 70 110 200 250 250 300 Fuse UL (SCCR) Short Circuit Current Rating kA 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 10 10 10 -

DOL

J7TKN-A J7TKN-B

J7TKN-C J7TKN-D

J7TKN-E J7TKN-F

0. 12 0. 18 0. 27 0. 4 0. 6 0. 8 1. 2 1. 8 2. 7 4 6 8 10 13 17 23 28 40 52 60 60 80 all ranges

0. 18 0. 27 0. 4 0. 6 0. 9 1. 2 1. 8 2. 7 4 6 9 11 14 18 24 32 42 52 65 74 90 120

7 10. 5 14 18 23 30 40 48 70 90 104 104 140

10. 5 15. 5 19 24 31 41 55 73 90 112 128 156 207

A A A A 0. 5*2 0. 5*2 25 1. 0*2 25 1. 0*2 2 2 25 2 2 25 4 4 25 4 4 25 2 6 6 25 2 10 10 25 4 16 10 25 4 20 16 25 6 35 25 35 10 35 25 35 16 50 35 63 16 50 35 63 20 63 50 63 25 80 63 80 35 100 80 150 50 160 100 150 63 160 125 150 80 160 125 150 80 For short circuit protecting overload relays with current transformer use fuse according to the contactor of the combination.

*1) Coordination-type according to IEC 947-4-1: , , 2": Light contact welding accepted. Thermal overload relay must not be damaged. , , 1": Welding of contactor and damage of the thermal overload relay allowed. *2) Miniature fuse

Tripping Characteristics for J7TKN-A, J7TKN-B, J7TKN-C, J7TKN-D

Detailed tripping times for each range see table page 58 with three-phase load with two-pole load

Tripping time min. s Average value of typical tolerance curves from cold condition Proceeding from service conditions the times decrease to 20-30% of the characteristic values

Tripping time min. [. . . ] multiplication factor

K

60

Thermal Overload Relay J7TKN

Position of Terminals

J7TKN-A J7TKN-B J7TKN-C; J7TKN-D

Thermal Overload Relays

Data according to IEC 947-4-1, IEC 947-5-1, VDE 0660, EN 60947-4-1, EN 60947-5-1

Type Rated insulation voltage Ui*1 Permissible ambient temperature operation storage Trip class according to IEC 947-4-1 Cable cross-section main connector solid or stranded flexible flexible with multicore cable end Cables per clamp auxiliary connector number solid flexible flexible with multicore cable end Cables per clamp Auxiliary contacts Rated insulation voltage Ui*1 same potential different potential Utilization category AC15 Rated operational current Ie 24V 230V 400V 690V Utilization category DC13 Rated operational current Ie 24V 110V 220V Short circuit protection (without welding 1kA) highest fuse rating Setting range Power loss per current path (max. ) minimum setting value maximum setting value W W 1. 1 2. 3 1. 1 2. 3 1. 3 3. 3 2. 9 4. 5 1. 1 2. 5 gL (gG) A A 6 to 23 4 all 6 28-42 6 52-65 6 all 6 A A A 1. 2 0. 15 0. 1 1 0. 15 0. 1 1. 2 0. 15 0. 1 1. 2 0. 15 0. 1 1. 2 0. 15 0. 1 1. 2 0. 15 0. 1 A A A A 5 3 2 0. 6 3 2 1 0. 5 4*5 2. 5 1. 5 0. 6 4*5 2. 5 1. 5 0. 6 5 3 2 0. 6 5 3 2 0. 6 V~ V~ 690 440 690 440 690 250 690 250 690 440 690 440 number mm² mm² mm² mm² 0. 75-6 + 0. 75-2. 5*2 mm² 0. 75-4 + 0. 5-2. 5*2 mm² 0. 5-2. 5 + 0. 5-1. 5 1+1 0. 75-6 1-4 0. 75-4 2 0, 75-10 0, 75-6 0. 75-6 2 4-35*2 6-25*2 4-25 1 0. 75-2. 5*2 0. 5-2. 5*2 0. 5-1. 5 2

*3 *4

J7TKN-A V~ 690

J7TKN-B 690

J7TKN-C 690

J7TKN-D 690

J7TKN-E 750

J7TKN-F 690

open

°C °C 10A 10A 10A

-25 to +60 -50 to +70 10A 20 20

*1) Suitable for: earthed-neutral systems, overvoltage category I to III, pollution degree 3 (standard-industry: Uimp = 4kV (at 440V), 6kV (at 690V). *2) Maximum cable cross-section with prepared conductor *3) Without terminals, suitable for bushing one connector 70mm² (stranded) per phase *4) Busbar sets see accessories page 57 *5) Switching capacity of the start contact: AC15 300VA, max. 1. 5A

Thermal Overload Relay

J7TKN

61

Data according to CULUS

Type Rated insulation voltage Rated current Auxiliary contacts Rated voltage same potential different potential Switching capacity AC of aux. [. . . ]