Detailed instructions for use are in the User's Guide.

[. . . ] AsapartoftheSANYOproductline worldwide, theCellProcessingWork StationexemplifiesouruniqueVertical ComponentIntegrationTMapproachto productdevelopment, combiningideas andinnovationsfromourglobalindustrial andconsumerproductsnetworkintoan integratedproductfeaturingadvanced technology, controls, constructionand performanceattributes. TheCPWSandsubcomponentsystems havebeenextensivelytestedtomeetthe toughestqualitystandardsforperformance, ergonomicsandcostofownership. TheCPWSisdesignedtominimize itscarbonfootprintthroughenergysavingsandenvironmentalstewardship.

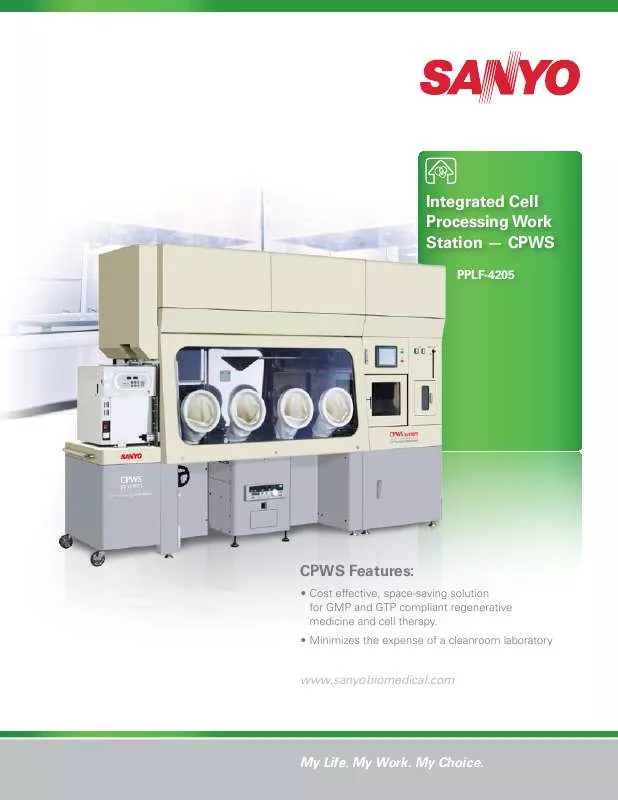

Self-Contained System, Small Footprint

TheSANYOconceptofaself-contained workstationisenabledbythecompany's demonstratedproficiencyforin situ decontaminationrequiredtoseparate processesfromonepatienttothenext, oroneprotocoltoanother. Byusinga highlyeffectiveH2O2decontamination process, theCPWScanbecompletely sterilizedwithoutheatandpreparedfor thenextprotocolwithintwohoursas comparedtoacleanroomdecontaminationfunctioncantakedaysorweeks. Byincreasingthroughputwithinthe parametersofGMPcomplianceandFDA guidelines, theCPWSisdeployedfor both research, cellularmanipulationand growth, cellproductextractionand emergingprocessesthatfallwithin similarguidelines. Currentandfutureapplicationsofthe CPWSincludeorganandtissueregenerationsuchasskin, cartilage, alveolarbone,

On the Work Surface

Sincehumansremainthesinglemost commonsourceofcontamination, the CPWSprovidesbothphysicalandprocessbenefitstominimizecontamination andcross-contaminationinthework area. Withinthefour-portgloveboxthe CPWSdeliversmorethanaconventional ClassII, TypeA2biologicalsafetycabinet typicallyinstalledwithinacleanroomto achievethesameobjective. Here, the manuallyinitiated, automaticallydeployed H2O2decontaminationprocesssupplementscontinuousHEPAfiltration. As 0. 3micronparticlesareremovedfrom thefreshairexchange, H2O2decontaminationneutralizescontaminantsbrought forthbyinstrumentationorequipment. [. . . ] · TheHEPAfilterandairflowsystemis mountedontopoftheisolator. · Theinternalairflowsystemisdesigned tocreateapositivepressuretomitigate thepossibilityofinflowcontamination. · Viabilityofthecontainmentarea isnotdelegatedtothird-partycleanroomcontractorswhoarehiredto decontaminate. · Theinconvenienceandexpenseof cumbersomecontainmentssuitswith airandvacuumhosesiseliminated. If workingwithBL3agents, thebuddy systemisnotrequired. · Thebarriereliminatesthepotential forroomcontaminationfromblood orotheraerosols. Workflowisnot impactedbyroutinecolds. · Staffconfidenceintotalcontainment improvesmorale. · Gloveportspermiteasierhandlingof redbagmaterialswhenrequired. · A6ºangledfrontincludesthreeglove portstopermitaccesstoallinterior surfaces. · Theinteriorcabinetincludesindependentinteriorfluorescentlampsto supplementambientlight.

Ergonomics and Safety

Becausesecondgowningisnotrequired, usercomfortandproductivityissignificantlyimproved. Theworkplaceroutine, includingbathroombreaks, isunencumberedbytheneedtoleaveandre-enter acleanroom, bleachand/orshower.

7

SANYO CPWS Series Features

Aseptic Environment Required for Cell Preparation Usually, human derived cells must be guaranteed that they are prepared and cultured in an aseptic environment because they cannot be treated by heat or pressure.

Extraction

Preparation

Culture

Administration

Original Cells

Prepared Cells

Standard of Particle Control

ISO14644-1 Class5 Class7 FDA Class100 InOperation3, 520 Class10, 000 InOperation35, 200 Class100, 000 InOperation3, 520, 000 -- EU-GMP Annex 1 GradeA InOperation3, 500 GradeB InOperation350, 000 Atrest3, 500 GradeC InOperation3, 500, 000 Atrest350, 000 GradeD Atrest3, 500, 000 JP GradeA InOperation3, 520 GradeB InOperation352, 000 Atrest3, 520 GradeC InOperation3, 520, 000 Atrest352, 000 GradeD Atrest3, 520, 000 WHO-GMP TRS902 Annex 6 GradeA InOperation3, 500 GradeB InOperation350, 000 Atrest3, 500 GradeC InOperation3, 500, 000 Atrest350, 000 GradeD Atrest3, 500, 000

Class8 Class9

H2O2 Decontamination System

· Themanuallyinitiated, automatically sequencedH2O2decontamination systemoffersafast, safeandproven sterilizationprocesstoenhance theperformanceoftheCPWSby allowingmorefrequentturnoverof segregatedcelllines. · ThevalidatedH2O2systemgenerates anH2O2vaporthatpermeatesall exposedsurfacesfromthecentral interchangepassboxnebulizer containingareplaceablebottleof enrichedhydrogenperoxide. · Whendeployed, theH2O2vaporization sequencedecontaminatesthepass box, workstationinterior, centrifuge andCO2incubatorexteriorand dockinggaskets. · Oncethevaporizationiscomplete, theH2O2programimplementsa dwellperiodtoensurethatproper exposuretimesaremaintainedfor awiderangeofpathogens(contact SANYOforindependenttestresults). · Attheendofthepre-programmed dwellperiodaresolutionprocess eliminatesfumesandtoxicresiduals.

Isolator Interchange

· Theinterchangepassboxallowssafe accesstotheworkareaforsupplies, instruments, devices, sterilemedia andlabware. · Whenmaterialsarebroughtintothe workstationtheyarefirstpositioned insidetheinterchangeforH2O2 decontamination. · Decontaminationismanuallyinitiated andautomaticallysequencedonce started. · WhentheH2O2vaporizationprocessis complete, theinnerdoorisopenedand thetransferiscompleted. · Doorinterlockspermitsimultaneous openingtoprotectthebarrierisolator.

8

CWPS Integrated Cell Processing Work Station

www. sanyobiomedical. com

SANYO CPWS Series Aseptic Environment

Conventional GMP Cleanroom Facility (Open System) with Biological Safety Cabinets

6 m2 18 m2 16 m2 PS

Highest aspect level = Aseptic (safety cabinets, etc) Aseptic level Aseptic level Aseptic level high (B) low (D) mid (C) Aseptic level raised gradually (A)

PS

PS

PS

PS

-152ºC

Air lock General environment (not clean)

18 m2 -32ºC Cleanroom: The biological safety cabinets within the cleanroom are open systems which require a stricter background environment. Access in and out of the cleanroom must comply with gown-up protocols consistent with GMP facilities. Class 100 air is ultimately delivered to the work product in one or more biological safety cabinet(s) operating independent of the cleanroom. Decontamination is costly and time-consuming; changeover from one protocol to another is difficult and expensive.

11 m2

11 m2

10 m2

4 m2

PS

PS

PS

PS PS

10 m2

PS

16 m2

7 m2

3 m2

Class A (100)

Class B (10, 000)

Class C IO(100, 000)

Class D AR(100, 000)

SANYO CPWS, Barrier Isolator with Integrated Systems

TheSANYOCPWSofferssignificant throughputpotentialinacomparatively smallfootprint. · TheCPWScanbeinstalledinmanageableGradeD(Class100, 000) environment, providingbiologicaland physicalprotectionbetweenthework andtheuser.

PPLF-4205

-32ºC

· Accessthroughthegloveports improvesusercomfort. · TheintegralH2O2decontamination systemiscompletedinlessthantwo hours, permittingfrequentchangeover andassuringseparationintegrityfrom onecellprocesstothenext.

-152ºC

D 00, 000)

9

SANYO CPWS Series Features

CO2 Incubator

ThemodularCO2incubatorisanadaptationofthefull-performanceSANYO MCO-5AC(IS). Thisincubatorisdesigned forprecisetemperatureandCO2control withelevatedrelativehumiditytominimizecelldesiccation. [. . . ] · Themonitordisplaysrealtimeimages withtotalmagnificationof110×. · Imagescanbecapturedviaanon- contactphotosensor, 2. 4×1. 8mm formonitordisplayanddigital recording. · Astandardpersonalcomputer externaltotheasepticisolatorwork areaisusedfordataacquisitionand imagemanagement.

Observation Module Operator's Monitor

Images from PC

AC Power

Camera IF

Control/Relay Box PC for Capturing

Various Signals IF

Lighting VCC, GND Light Dimming Signal Cameral IF (power, image signals) Power SW Signal Capture SW Signal

12

CWPS Integrated Cell Processing Work Station

www. sanyobiomedical. com

SANYO CPWS Model PPLF-4025 Specifications

Component Specifications

Component BarrierIsolator InterchangePassBox AirflowandHEPAFiltrationSystem H2O2System Centrifuge CO2Incubator CellObservationSystem Description BaseUnit Included Included Included Optional Optional Optional

System Summary Specifications

Component BaseWorkStation, BarrierIsolator Interchange HEPAFiltrationSystem Centrifuge CellObservationModule CO2Incubator Order Number PPLF-4025 Included Included Optional Optional MCO-5AC(IS)

Centrifuge and Module

Feature ExteriorDimensions(wxf-bxh) MaximumSpeed MaximumCentrifugalAcceleration Controls, Alarms Pre-Sets TimeSettableRange Acceleration/DecelerationSettings MotorShaft Capacity Specification 21. 25"×22. 9"×30. 3"(540x582x771mm) 2100RPM 10to970Gcentrifugalaccelerationsettablerange Externallymounted, front, withfootswitchforcut-off. Doorlockstatusdisplayed. Upto4patternsinmemory 10to50seconds(10secondincrements);1to99minutes(1minuteincrements);andinfinite 3stage Stainlesssteel 1000ml(50mltubes, ×20)

13

SANYO CPWS Model PPLF-4025 Specifications

Barrier Isolator

Dimensions OverallExteriorDimensions(wxf-bxh) InteriorDimensions(wxf-bxh) InteriorWorkSurfaceElevation GloveElevation PassBoxInterchange(wxf-bxh) NetWeight Controls, Alarms PressureMonitor FanMotor Construction ExteriorFinish InteriorFinish FrontGlovePortPanel, Angle6° Air System AirQuality AirflowSystemandVelocity FiltrationSystem FiltrationSystem, PassBox IntakeandExhaust Relative Air Pressure Workstation PassBoxInterchange Interior Work Area Lighting ElectricalOutlet Pass Box Interchange Door Material Decontamination System Function H2O2ResolutionandAeration DecontaminationCycleTime Utilities Electrical Mainsystem, 4500w, 220V, AC, 60Hz. Electricaloutlet120V, AC, 60Hz. [. . . ]