Detailed instructions for use are in the User's Guide.

[. . . ] FM1200

INTRODUCTION

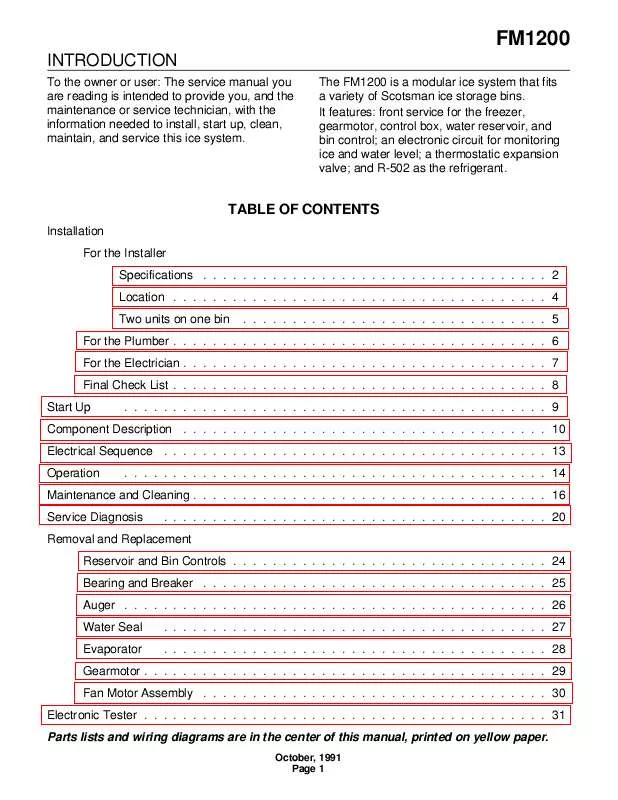

To the owner or user: The service manual you are reading is intended to provide you, and the maintenance or service technician, with the information needed to install, start up, clean, maintain, and service this ice system. The FM1200 is a modular ice system that fits a variety of Scotsman ice storage bins. It features: front service for the freezer, gearmotor, control box, water reservoir, and bin control; an electronic circuit for monitoring ice and water level; a thermostatic expansion valve; and R-502 as the refrigerant.

TABLE OF CONTENTS

Installation For the Installer Specifications . 4 Two units on one bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

For the Plumber . [. . . ] To remove the auger, remove the front and auger to dry: if the auger is not bright and top panels. Remove 3 hex studs holding ice chute Clean the auger and evaporator as required. Loosen band clamp under ice chute, and 9. Remove 4 allen screws holding breaker to evaporator.

October, 1991 Page 19

FM1200

SERVICE DIAGNOSIS: Condition - No Ice Being Produced

STATUS: NOTHING OPERATES

A. Check: Voltage to the unit, restore it if there is none. Check: The master switch, switch ON if off. Check: The 3 reset switches, (spout switch, or on prior models the circuit board), high and low pressure): depress and release each switch. If the still does not start, check: the spout switch; the high and the low side pressures. Check the low pressure cut out, if closed, go to E; if it is open, it could be due to: · Low refrigerant charge · The auger not turning · Restricted system · TXV not opening 1. Check the low side pressure, the low pressure cut out opens at pressure below 4 psig. Check if the auger is turning, if it is not, remove the gearbox and: Check for internal damage, repair and replace in the machine. Check for low charge, add some refrigerant, if the unit will operate, (normal low side pressure being about 30 psig) stop and look for a leak, repair, replace the drier, evacuate, and weigh in the nameplate charge. If, with added charge, the unit does not operate: Check for a restricted system, replace the drier, evacuate, and weigh in a nameplate charge. Check for a Thermostatic Expansion Valve that does not open, if defective, replace it. Replace the drier, evacuate, and weigh in the nameplate charge. Check the high pressure cut out, if closed go to F, if open check 1. The pressure control opens at 450 psig. Check the high side pressure, reset the control, and observe: on water cooled, that water soon begins to flow from the condenser drain; or, on air cooled, that the fan is forcing air through the condenser. If the unit trips out on pressures below 450 psig, replace the control. If the pressures rise above the trip out point, and the unit shuts down: a. Check for adequate water flow on water cooled, if adequate, clean the interior of the condenser. If the pressures are still too high replace the water regulating valve. Check for adequate air flow on air cooled. [. . . ] Bench test the gearmotor, check for oil leaks, noise, and amp draw.

GEAR CASE

October, 1991 Page 29

FM1200

CIRCUIT BOARD TESTING

///////////////////////////////////////////////////////////////////////WARNING////////////////////////////////////////////////////////////////// These procedures require the machine to be connected to the power supply. The voltages of the electronic circuit are very low, but HIGHER VOLTAGES ARE PRESENT IN THE UNIT. Do not touch anything but the tester while the unit is being checked out. Make all connections to the circuit board with the ELECTRICAL POWER OFF. [. . . ]