Detailed instructions for use are in the User's Guide.

[. . . ] INTRODUCTION

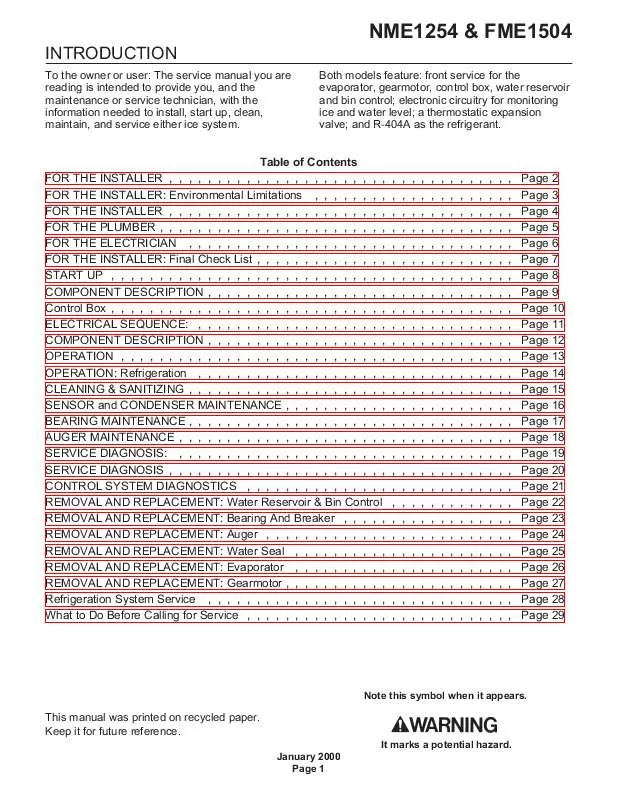

To the owner or user: The service manual you are reading is intended to provide you, and the maintenance or service technician, with the information needed to install, start up, clean, maintain, and service either ice system.

NME1254 & FME1504

Both models feature: front service for the evaporator, gearmotor, control box, water reservoir and bin control; electronic circuitry for monitoring ice and water level; a thermostatic expansion valve; and R-404A as the refrigerant.

Table of Contents FOR THE INSTALLER , , , , , , , , , , , , , , , , , , , , , , , FOR THE INSTALLER: Environmental Limitations , , , , , , , , FOR THE INSTALLER , , , , , , , , , , , , , , , , , , , , , , , FOR THE PLUMBER , , , , , , , , , , , , , , , , , , , , , , , , FOR THE ELECTRICIAN , , , , , , , , , , , , , , , , , , , , , FOR THE INSTALLER: Final Check List , , , , , , , , , , , , , , START UP , , , , , , , , , , , , , , , , , , , , , , , , , , , , , COMPONENT DESCRIPTION , , , , , , , , , , , , , , , , , , , Control Box , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ELECTRICAL SEQUENCE: , , , , , , , , , , , , , , , , , , , , COMPONENT DESCRIPTION , , , , , , , , , , , , , , , , , , , OPERATION , , , , , , , , , , , , , , , , , , , , , , , , , , , , OPERATION: Refrigeration , , , , , , , , , , , , , , , , , , , , CLEANING & SANITIZING , , , , , , , , , , , , , , , , , , , , , SENSOR and CONDENSER MAINTENANCE , , , , , , , , , , , BEARING MAINTENANCE , , , , , , , , , , , , , , , , , , , , , AUGER MAINTENANCE , , , , , , , , , , , , , , , , , , , , , , SERVICE DIAGNOSIS: , , , , , , , , , , , , , , , , , , , , , , SERVICE DIAGNOSIS , , , , , , , , , , , , , , , , , , , , , , , CONTROL SYSTEM DIAGNOSTICS , , , , , , , , , , , , , , , REMOVAL AND REPLACEMENT: Water Reservoir & Bin Control REMOVAL AND REPLACEMENT: Bearing And Breaker , , , , , REMOVAL AND REPLACEMENT: Auger , , , , , , , , , , , , , REMOVAL AND REPLACEMENT: Water Seal , , , , , , , , , , REMOVAL AND REPLACEMENT: Evaporator , , , , , , , , , , REMOVAL AND REPLACEMENT: Gearmotor , , , , , , , , , , , Refrigeration System Service , , , , , , , , , , , , , , , , , , , What to Do Before Calling for Service , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

, , , , , , , , , , , , , , , , , , , , , , , , , , , ,

Page 2 Page 3 Page 4 Page 5 Page 6 Page 7 Page 8 Page 9 Page 10 Page 11 Page 12 Page 13 Page 14 Page 15 Page 16 Page 17 Page 18 Page 19 Page 20 Page 21 Page 22 Page 23 Page 24 Page 25 Page 26 Page 27 Page 28 Page 29

Note this symbol when it appears.

This manual was printed on recycled paper. Keep it for future reference.

January 2000 Page 1

It marks a potential hazard.

NME1254 & FME1504

FOR THE INSTALLER

These machines are designed to fit the following Scotsman storage bins: · SB480 and extensions (with bin top KBT18)

· HTB555 or BH550 - direct fit · BH800 using bin top KBT23 · BH801 using bin top KBT29 · BH900 using bin top KBT22

NME1254 Dispenser Applications The NME1254 can be placed on and used with certain ice and ice-beverage dispensers. ·ID200 or ID250, use adapter KBT44 and KNUGDIV and KDIL-N-ID2

·Cornelius ED/DF200 beverage

KBT44 and KDIL-N-250

dispensers, use KBT44 and KDIL-N-200

·Cornelius ED/DF250 beverage dispensers, use ·Lancer special-for-nugget Ice Beverage

Dispenser, use KDIL-N-L & Lancer kit #82-3491

ICE MACHINE SPECIFICATIONS

Model Number Cabinet Dimensions W" x D" x H" 30 x 24 x 27 30 x 24 x 27 30 x 24 x 27 30 x 24 x 27 Basic Electrical 208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1 Condenser Type Ice Type Refrigerant Charge (R-404A) Air Cooled Flake 36 ounces Water Cooled Flake 24 ounces Air Cooled Nugget 36 ounces Water Cooled Nugget 24 ounces January 2005 Page 2 Minimum Circuit Ampacity 15. 0 14. 3 15. 0 14. 3 Maximum Fuse Size 20 20 20 20

FME1504AS-32B FME1504WS-32B NME1254AS-32B NME1254WS-32B

Minimum circuit ampacity is used to determine wire size per National Electric Code.

FOR THE INSTALLER: Environmental Limitations

Installation Limitations: This ice system is designed to be installed indoors, in a controlled environment: Min. Air Temperature 500F 1000F Water Temperature 400F 1000F Water Pressure 20 psi 80 psi Voltage 198 253 (Compared to the nameplate) Operating the machine outside of the limitations is misuse and can void the warranty.

NME1254 & FME1504

Water Limitations An ice machine makes food. [. . . ] Check with a water treatment specialist regarding water treatment. For more information on removal of these parts, see REMOVAL AND REPLACEMENT. To remove the auger, remove the front and top panels. Push back bail clamp holding ice chute cover to ice chute, and remove cover. Remove 4 allen screws holding breaker to evaporator. Drain the evaporator by lowering and uncapping the evaporator drain hose. After the auger has been removed, allow the auger to dry: if the auger is not bright and shiny, it must be cleaned. Clean the auger and evaporator as required. Reverse to reassemble.

BREAKER & BEARING & AUGER ASSEMBLY

Handle auger with care, it has sharp edges.

June 2002 Page 18

SERVICE DIAGNOSIS:

Symptom No ice is made, nothing operates Possible Cause Unit off due to no power

NME1254 & FME1504

Probable Correction Restore Power Switch master switch to ON. Check water supply, filter, strainer, float valve. Check for water interruption (water cooled) or fan motor failure (air cooled). Circuit board has not yet shut unit down. Circuit board has shut ice machine down due to high auger motor amp draw. Check for cause of high amp draw, including bearings, gearmotor condition and scale on auger and in evaporator. Auger not turning due to: motor failure; auger relay failure on circuit board; or gears stripped. Check for a restricted system

Unit off due to master switch in OFF position. Unit off due to ice level sensors (photo-electric eyes) blocked. Unit off due to scale on water level sensor. Unit off due to high pressure control open. Unit is shut down

Low pressure control open

No power to circuit board.

Check harness Low or high pressure cut outs open

Circuit Board gear motor relay will not Check, replace board close Water level or ice level sensor failed. No ice, auger motor is turning Compressor contactor coil is open Compressor will not start Check, replace sensor Check/replace contactor Check start capacitor. Check start relay Check compressor windings Circuit board compressor relay will not close. [. . . ] ·Special leak detection equipment is required to 5. Shut the low side access valve at the ice detector capable of detecting a Halongenated machine. Open the discharge manifold valve full open. the leak detector manufacturer if in doubt. [. . . ]