User manual SIMRAD ARCTIC TANK OUTLINE DIMENSIONS SCHEMA REV A

Lastmanuals offers a socially driven service of sharing, storing and searching manuals related to use of hardware and software : user guide, owner's manual, quick start guide, technical datasheets... DON'T FORGET : ALWAYS READ THE USER GUIDE BEFORE BUYING !!!

If this document matches the user guide, instructions manual or user manual, feature sets, schematics you are looking for, download it now. Lastmanuals provides you a fast and easy access to the user manual SIMRAD ARCTIC TANK OUTLINE DIMENSIONS. We hope that this SIMRAD ARCTIC TANK OUTLINE DIMENSIONS user guide will be useful to you.

Lastmanuals help download the user guide SIMRAD ARCTIC TANK OUTLINE DIMENSIONS.

Manual abstract: user guide SIMRAD ARCTIC TANK OUTLINE DIMENSIONSSCHEMA REV A

Detailed instructions for use are in the User's Guide.

[. . . ] Several minor changes to other descriptions and illustrations. Interactive version on the document (CHM format) introduced.

Rev. H

September 2006

Copyright

©2006 Simrad Horten AS The information contained in this document remains the sole property of Simrad Horten AS. No part of this document may be copied or reproduced in any form or by any means, and the information contained within it is not to be communicated to a third party, without the prior written consent of Simrad Horten AS.

Disclaimer

Simrad Horten AS endeavours to ensure that all information in this document is correct and fairly stated, but does not accept liability for any errors or omissions. The document can be changed without prior notice.

Warning

The equipment to which this manual applies must only be used for the purpose for which it was designed. [. . . ] The box keel is already the deepest part of the vessel. If the box keel is too narrow to accommodate the transducer, it can be widened, either symmetrically or to one side only. In the last case the installation could also be described as a blister merged into the keel.

Mounting and clamping rings

Circular transducers may be provided with mounting and clamping rings, or with drawings to allow for local production of these. The mounting ring is welded to the hole in the box keel, while the clamping ring fits around the edge of the transducer body. Bolts through the clamping ring into the mounting ring will then secure the transducer between them. Note that several transducers use direction guides to allow correct mounting.

Smooth surface

Mounting screws or bolts must not be extruding from the box keel. Ensure that the surface of the transducer face, the box, the hull plating and putty around the transducer is as even and smooth as possible. Obstructions on these surfaces will create problems with turbulant flow.

Horizontal support bar

Large diameter transducers must be fitted with a horizontal support bar. This bar can be secured to the mounting ring using threaded rods.

22

851-160164/H

Ways of mounting the transducer

Example

The figure below illustrates a symmetrical box keel installation.

(CD17011A)

D C B E A

(A) = Box keel (B) = U-shaped support bar (only required on large transducers) (C) = Stuffing tube (D) = Cable in steel conduit (E) = Cable service loop

851-160164/H

23

Simrad Echo sounder transducers

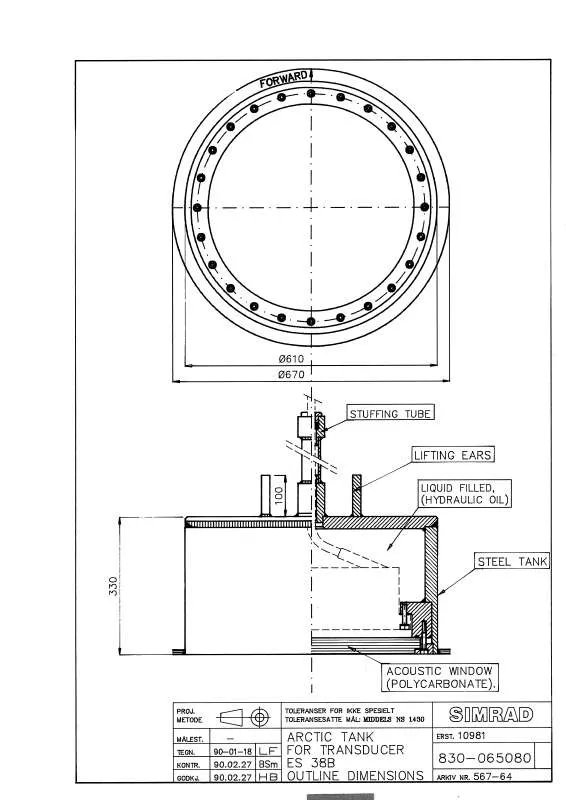

Flush mounting in a steel tank

Flush mounting is used on very large vessels with a hull so deep that no air bubbles are found below the hull, and on vessels operating in shallow harbours or waters, where a protruding blister can not be accepted. The standard procedure for flush mounting on a steel vessel is to weld a steel tank inside the hull, and mount the transducer into this tank.

Mounting and clamping rings

Circular transducers may be provided with mounting and clamping rings, or with drawings to allow for local production of these. The mounting ring is welded to the hole in the hull plating, while the clamping ring fits around the edge of the transducer body. The loss varies with the distance between transducer face and the hull. The best result is obtained when the distance is half a wavelength. In addition to the loss, the beam pattern is degraded, because a larger area of the hull is set into vibrations.

Mounting and clamping rings

Circular transducers may be provided with mounting and clamping rings, or with drawings to allow for local production of these. The mounting ring is welded to the hole inside the steel tank, while the clamping ring fits around the edge of the transducer body. Bolts through the clamping ring into the mounting ring will then secure the transducer between them. Note that several transducers use direction guides to allow correct mounting.

Smooth surface

Mounting screws or bolts must not be extruding from the acoustic window. Ensure that the surface of the window, the hull plating and putty around the transducer is as even and smooth as possible. Obstructions on these surfaces will create problems with turbulant flow.

Horizontal support bar

Large diameter transducers must be fitted with a horizontal support bar. This bar can be secured to the mounting ring using threaded rods.

28

851-160164/H

Ways of mounting the transducer

Example

The transducer shown in the figure below is mounted inside the hull. The tank is filled with oil.

G D A B

H F

E

(CD017012C)

C

(A) = Steel tank (B) = Oil (C) = Hull plating (D) = Cable service loop (E) = Stuffing tube (F) = Cable in steel conduit (G) = Hole for oil filling (H) = Air outlet

851-160164/H

29

Simrad Echo sounder transducers

Drop keel

The use of a drop keel with the purpose of stabilising the vessel is well known. A drop keel is also a superior platform for echo sounder transducers. [. . . ] We also recommend that you install the transducer cable in a steel conduit.

Related topics

Cable splicing on page 36 Steel conduit on page 37

58

851-160164/H

GPT transducer terminations

Sidescan transducer

This is the termination of the transducer cable from two sidescan transducers (port and starboard) to the socket on the General Purpose Transceiver Unit (GPT). The other end of each cable is permanently fixed to the transducers. If only one sidescan transducer is used, connect is as a port side unit to terminals C and D on the GPT socket.

GPT Transducer socket

L K E F H J

B C D

A

N M

Transducer cable Port side

Junction Box (1:1) (Optional)

C D

Screen Connect to plug housing

Transducer cable Starboard side

Junction Box (1:1) (Optional)

H J

Screen Connect to plug housing

W802-7 Rev. D

Dual frequency sidescan termination

If you need to splice the transducer cable, it is very important to use the correct cable, and to avoid ground loops. We strongly recommend the use of a junction box. [. . . ]

DISCLAIMER TO DOWNLOAD THE USER GUIDE SIMRAD ARCTIC TANK OUTLINE DIMENSIONS Lastmanuals offers a socially driven service of sharing, storing and searching manuals related to use of hardware and software : user guide, owner's manual, quick start guide, technical datasheets...manual SIMRAD ARCTIC TANK OUTLINE DIMENSIONS