Detailed instructions for use are in the User's Guide.

[. . . ] A05-012

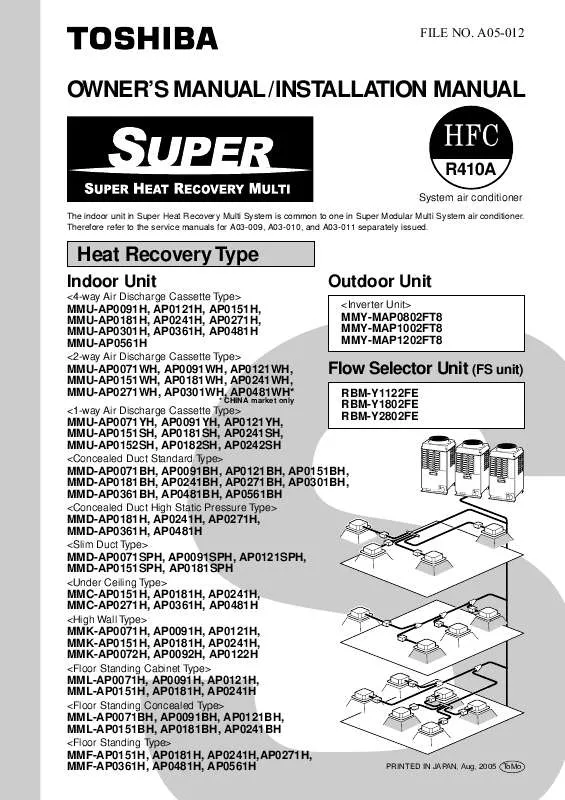

OWNER'S MANUAL / INSTALLATION MANUAL

R410A

System air conditioner

The indoor unit in Super Heat Recovery Multi System is common to one in Super Modular Multi System air conditioner. Therefore refer to the service manuals for A03-009, A03-010, and A03-011 separately issued.

Heat Recovery Type

Indoor Unit

<4-way Air Discharge Cassette Type>

Outdoor Unit

<Inverter Unit>

MMU-AP0091H, AP0121H, AP0151H, MMU-AP0181H, AP0241H, AP0271H, MMU-AP0301H, AP0361H, AP0481H MMU-AP0561H

<2-way Air Discharge Cassette Type>

MMY-MAP0802FT8 MMY-MAP1002FT8 MMY-MAP1202FT8

MMU-AP0071WH, AP0091WH, AP0121WH, MMU-AP0151WH, AP0181WH, AP0241WH, MMU-AP0271WH, AP0301WH, AP0481WH*

* CHINA market only

Flow Selector Unit (FS unit)

RBM-Y1122FE RBM-Y1802FE RBM-Y2802FE

<1-way Air Discharge Cassette Type>

MMU-AP0071YH, AP0091YH, AP0121YH, MMU-AP0151SH, AP0181SH, AP0241SH, MMU-AP0152SH, AP0182SH, AP0242SH

<Concealed Duct Standard Type>

MMD-AP0071BH, AP0091BH, AP0121BH, AP0151BH, MMD-AP0181BH, AP0241BH, AP0271BH, AP0301BH, MMD-AP0361BH, AP0481BH, AP0561BH

<Concealed Duct High Static Pressure Type>

MMD-AP0181H, AP0241H, AP0271H, MMD-AP0361H, AP0481H

<Slim Duct Type>

MMD-AP0071SPH, AP0091SPH, AP0121SPH, MMD-AP0151SPH, AP0181SPH

<Under Ceiling Type>

MMC-AP0151H, AP0181H, AP0241H, MMC-AP0271H, AP0361H, AP0481H

<High Wall Type>

MMK-AP0071H, AP0091H, AP0121H, MMK-AP0151H, AP0181H, AP0241H, MMK-AP0072H, AP0092H, AP0122H

<Floor Standing Cabinet Type>

MML-AP0071H, AP0091H, AP0121H, MML-AP0151H, AP0181H, AP0241H

<Floor Standing Concealed Type>

MML-AP0071BH, AP0091BH, AP0121BH, MML-AP0151BH, AP0181BH, AP0241BH

<Floor Standing Type>

MMF-AP0151H, AP0181H, AP0241H, AP0271H, MMF-AP0361H, AP0481H, AP0561H

PRINTED IN JAPAN, Aug, 2005 ToMo

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the conventional refrigerant R22 in order to prevent destruction of the ozone layer. Thank you very much for purchasing TOSHIBA Air Conditioner. Please read this owner's manual carefully before using your Air Conditioner. [. . . ] capacity of connected indoor units 3 units 84. 0 kW 48 units H2 < 15 m 135% ( 3) H2 > 15 m 105% Outdoor capacity : 70%

*

*3 :

MMY-MAP1202FT8 up to 120%.

38

5

REFRIGERANT PIPING

Airtight test

After the refrigerant piping has finished, execute an airtight test. For an airtight test, connect a nitrogen gas bomb as shown in the figure below, and apply pressure. · Be sure to apply pressure from the service ports of the packed valves (or ball valves) at liquid side, discharge gas side, balance pipe and suction gas side. · An air tight test can be only performed to the service ports at liquid side, discharge gas side, and suction gas side of the outdoor unit. · Close fully valves at liquid side, discharge gas side, balance pipe and suction gas side. As there is possibility that nitrogen gas enters in the refrigerant cycle, re-tighten the valve rods before applying pressure. (Re-tightening of the valve rods are unnecessary for valves at discharge gas side because they are ball valves. ) · For each refrigerant line, apply pressure gradually with steps at liquid side, discharge gas side, balance pipe and suction gas side.

Be sure to apply pressure to suction gas side, discharge gas side, liquid side and balance pipe.

REQUIREMENT

Never use "Oxygen", "Flammable gas" and "Noxious gas" in an airtight test.

LowHighpressure pressure gauge gauge VL VH Gauge manifold

Connected to indoor unit Main pipe Packed valve fully closed (Suction gas side) Outdoor unit

Detailed drawing of packed valve

Suction gas side service port To gauge manifold Discharge gas side service port Discharge gas side ball valve Liquid side service port Liquid side packed valve To outdoor unit Piping at site Suction gas side packed valve

Brazed Service port Fully closed Service port Ball valve fully closed (Discharge gas side) Fully closed Ø6. 4 Copper pipe

Reducing valve

To outdoor unit

Ø6. 4 Copper pipe Nitrogen gas

Piping at site Balance pipe service port To outdoor unit

Piping at site Piping at site

Balance pipe packed valve

Fully closed

Packed valve fully closed (Liquid side)

Connected to follower outdoor units

Packed valve fully closed (Balance pipe)

STEP 1 : Apply pressure 0. 3MPa (3. 0kg/cm2G) for 3 minutes or more. Available to detect a gross leakage STEP 2 : Apply pressure 1. 5MPa (15kg/cm2G) for 3 minutes or more. STEP 3 : Apply pressure 3. 73MPa (38kg/cm2G) for approx. Available to detect slow leakage · Check pressure down. No pressure down: Accepted Pressure down: Check the leaked position. However, if there is difference of ambient temp. between when pressure has been applied and when 24 hours passed, pressure changes by approx.

Leaked position check

When a pressure-down is detected in STEP 1, STEP 2, or STEP 3, check the leakage at the connecting points. Check leakage with hearing sense, feeler, foaming agent, etc, and perform re-brazing or re-tightening of flare if leakage is detected.

39

Air purge

For the air purge at installation time (Discharge of air in connecting pipes), use "Vacuum pump method" from viewpoint of protection of earth environment. · For protection of earth environment, do not discharge the flon gas in the air. · Using a vacuum pump, eliminate the remained air (nitrogen gas, etc. ) in the unit. If gas remains, an absence of faculties may be caused. After the airtight test, discharge nitrogen gas. Then connect the gauge manifold to the service ports at suction gas side, discharge gas side and liquid side, and connect the vacuum pump as shown in the following figure. Be sure to perform vacuuming for suction gas side, discharge gas side, liquid side and balance pipe. · Be sure to perform vacuuming from both suction gas side, discharge gas side, liquid side and balance pipe. [. . . ] Fasten the wiring cover surely with screws. Connect the control wire taken out through the slit on the terminal block and the control wire from the Flow Selector unit at the relay terminal section.

Earth line Terminal block Terminal block

Cord clamp Screw Screw Screw

Control wire

Control wire from the Flow Selector unit

Power supply cable for Flow Selector unit Slit of the terminal block Wiring cover

Floor Standing Cabinet Type (MML-AP 1H Series)

Earth screw for Flow Selector unit Earth screw Indoor P. C. board CN081 (Black)

Attached wire (Control wiring) Cord clamp

Attached wire (Power supply)

Faston connection R(L), S(N) terminal block for power supply

84

6

ELECTRIC WORK

Floor Standing Concealed Type (MML-AP 1BH Series)

Indoor P. C. board

Faston connection

Earth screw for Flow Selector unit

Attached wire (Control wiring)

DON'T APPLY 220-240V

R(L) S(N)

FOR INTER-UNIT

FOR REMOTE CONTROL

CN081

Attached wire (Power supply) R(L), S(N) terminal block for power supply Earth screw

Cord clamp

Power supply

85

n Setting when connecting multiple indoor units to a FS unit Cautions to connection of indoor unit

· When connecting the multiple indoor units to a single FS unit, it is necessary to set up the Item code. [. . . ]