Detailed instructions for use are in the User's Guide.

[. . . ] The elimination of an air system, common with dry disc brakes, improves reliability and reduces maintenance costs.

4

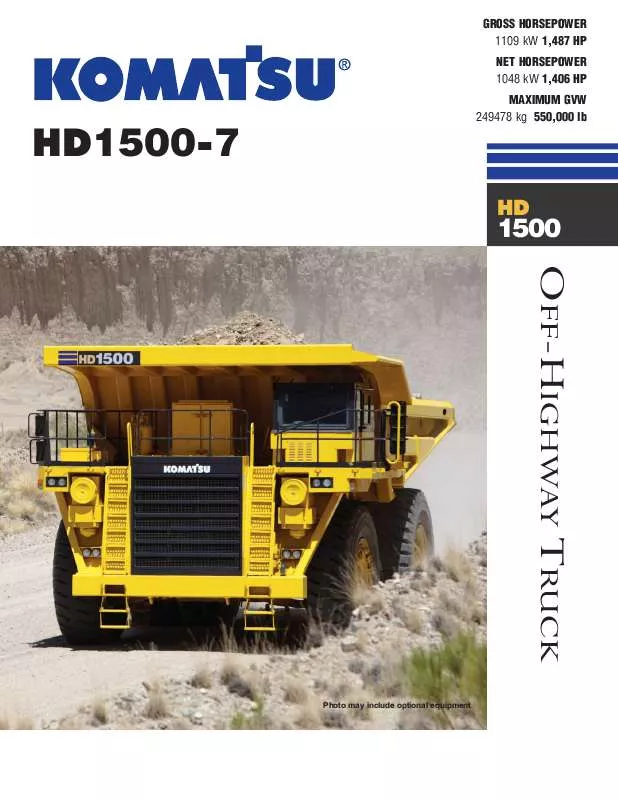

O F F - H I G H WAY T R U C K

HD1500-7

Auto Retard Speed Control (ARSC)

ARSC allows the operator to simply set the downhill travel speed and go down slopes at a constant speed. This allows the operator to concentrate on steering. The speed can be set at increments of 1 km/h 0. 6 MPH per click (±5 km/h 3. 1 MPH of setting speed adjustment) to match the optimum speed for the slope. The retarder cooling oil temperature is constantly monitored and the descent speed is automatically reduced, if necessary.

Automatic Idling Setting System (AISS)

This system facilitates quick engine warm-up and cab cooling/warming. [. . . ] Hoist times Power Up: 15 sec Power Down: 15 sec

Wet multi-disc brakes and fully hydraulic controlled braking systems realize lower maintenance

costs and higher reliability. Wet disc brakes are fully sealed to keep contaminants out, reducing wear and maintenance. Brakes require no adjustments for wear, meaning even lower maintenance. Service brake and retarder are isolated from the other truck hydraulic functions to ensure reliable performance. The parking brake is a spring applied, oil released, 3 caliper dry disc mounted on the input yoke to the differential. Fully hydraulic braking systems eliminate the air system; air bleeding is not required, and water condensation that can lead to contamination, corrosion, and freezing is eliminated.

8

O F F - H I G H WAY T R U C K

HD1500-7

DASH-7 FEATURES

Komatsu Components

Komatsu manufactures the torque converter, transmission, hydraulic cylinders, and electrical parts on this dump truck. Komatsu dump trucks are manufactured with an integrated production system under strict quality control system guidelines.

Reliable Hydraulic System

A large capacity oil cooler is installed in each hydraulic circuit, improving the reliability of the hydraulic units during sudden temperature rises. Further, in addition to the main filter, a 10 = 3 (min) line filter is located at the entrance to the transmission control valve. This system helps prevent secondary faults.

High-Rigidity Frame

Front support is integrated with the frame. The frame rigidity has been substantially increased. As a result, flexural rigidity and torsional rigidity, which are indicators of drivability and ride quality, are significantly improved.

Flat Face-to-Face O-Ring Seals

Flat face-to-face O-ring seals are used to securely seal all hydraulic hose connections and to prevent oil leakage.

Hose

Nipple

O-ring

Sealed DT Connectors Rugged and Durable Dump Body Design

The standard dump body is made of high-tensile-strength steel with a Brinell hardness of 400 for excellent rigidity and reduced maintenance cost. The side and bottom plates of the dump section are reinforced with ribs for added strength. Main harnesses and controller connectors are equipped with sealed DT connectors providing high reliability, water resistance, and dust resistance.

Protection Function Supported by Electronic Control

Item Downshift inhibitor Over-run inhibitor Reverse inhibitor Function

Even if the driver downshifts accidentally, a speed appropriate to the current gear is automatically set, limiting potential over-runs.

When descending grades, if the vehicle's speed surpasses the maximum for the current gear, the front and rear brakes automatically operate, limiting potential over-runs.

The vehicle is prevented from moving backward when operating the body.

Forward/Reverse shift inhibitor This device makes it impossible to shift from forward to reverse when the vehicle's speed surpasses 4 km/hr 2. 5mph. Anti-hunting system Neutral safety

When running near a shift point, smooth automatic shifting takes place. The engine is prevented from starting when the shift lever is not in neutral.

9

HD1500-7 O F F - H I G H W A Y T R U C K

SPECIFICATIONS

ENGINE Model . Turbo-charged, after-cooled Number of cylinders . 159 mm x 190 mm 6. 26" x 7. 48" Piston displacement . Gross 1109 kW 1, 487 HP ISO 9249 / SAE J1349 . 9 mm 0. 35" Target area (inside length x width) . 7670 mm x 5705 mm 25'2"x 18'9" Dumping angle . Exhaust heating

TRANSMISSION Torque converter . 3-elements, 1-stage, 2-phase Transmission . [. . . ] Read from gross weight down to the percent of total resistance. From this weight resistance point, read horizontally to the curve with the highest obtainable speed range, then down to maximum descent speed the brakes can safely handle without exceeding cooling capacity.

11

STANDARD EQUIPMENT POWERTRAIN Air cleaner (2); battery disconnect; engine electronic control; engine electronic monitor; engine overspeed protection; engine pre-lube system; ground level shutdown; variable speed engine fan (electronic-over-hydraulic) Powertrain Management (these items located in the cab): transmission controller retard controller monitor display data download port Seven-speed automatic transmission: electronic control body-up reverse interlock body-up shift inhibitor downshift/reverse shift inhibitor neutral start switch transmission belly guard Torque converter (electronic lockup control) CAB Air conditioning (R134A) Electric windows (both doors) Glass, tinted Heater/defroster Instrumentation (gauge and monitor): speedometer tachometer engine coolant temperature brake oil temperature fuel lever shift indicator hourmeter odometer torque converter temperature warning lights Insulated and sound-suppressed Radio, AM/FM/Cassette Seat, air suspension (driver) Seat, passenger Seat belts 78 mm 3" retractable Steering wheel, tilt and telescopic Sun visor Windshield washer and wiper Heat shield behind engine Horn, electric (2) Ladder, deck-to-transmission Ladders, right and left (front) Mirrors, right and left Mud flaps Parking brake (3 caliper, spring-applied) Reverse hoist interlock Rock ejectors ROPS cab (integral 4-post) Secondary brake system, automatic and manual Skid-resistant walkway on deck Supplementary steering system, automatic Windshield, laminated safety glass OTHER Auto-Retard Speed Control (ARSC) Automatic Spin Regulator (ASR) Automatic lubrication system Body mounting group Fast fill fuel system (Wiggins) right-hand side of the machine Integrated Komatsu Payload Meter Operation, parts, and maintenance manuals (1 set) Rims (6), 24 x 51 (for 33 x 51 and 33R51 tires) Tow hooks, front Tow pin, rear Vehicle health monitoring system (VHMS)

LIGHTING Back-up light, rear (1) Back-up lights, deck-mounted (2) Clearance lights, front Engine service lights (2) Headlights, halogen (8) Hi-low beam selector Instrument panel lights Ladder lights, driver side Retarder lights (2) Stop and tail lights LED Turn signals LED GENERAL Back-up warning alarm Body up cable Cab guard (on canopy) Drive line protector (front and rear) Engine fan and pulley guards Exhaust pipe blanket Ground level engine shutdown Handrails

OPTIONAL EQUIPMENT (Optional equipment may change operating weight. ) Weights listed are approximate change from operating weight. 16 kg Fast fill fuel, Wiggins left-hand side . 2 kg 5 lb 29. 8 lb 35 lb 5 lb Fast oil change, Wiggins (engine) . [. . . ]