Detailed instructions for use are in the User's Guide.

[. . . ] If controller finds any abnormality, it is displayed on the LCD with code. Maintenance Function Monitor informs replacement time of oil and filters on LCD when the replacement interval is reached. Trouble Data Memory Function Monitor stores abnormalities for effective troubleshooting.

Engine

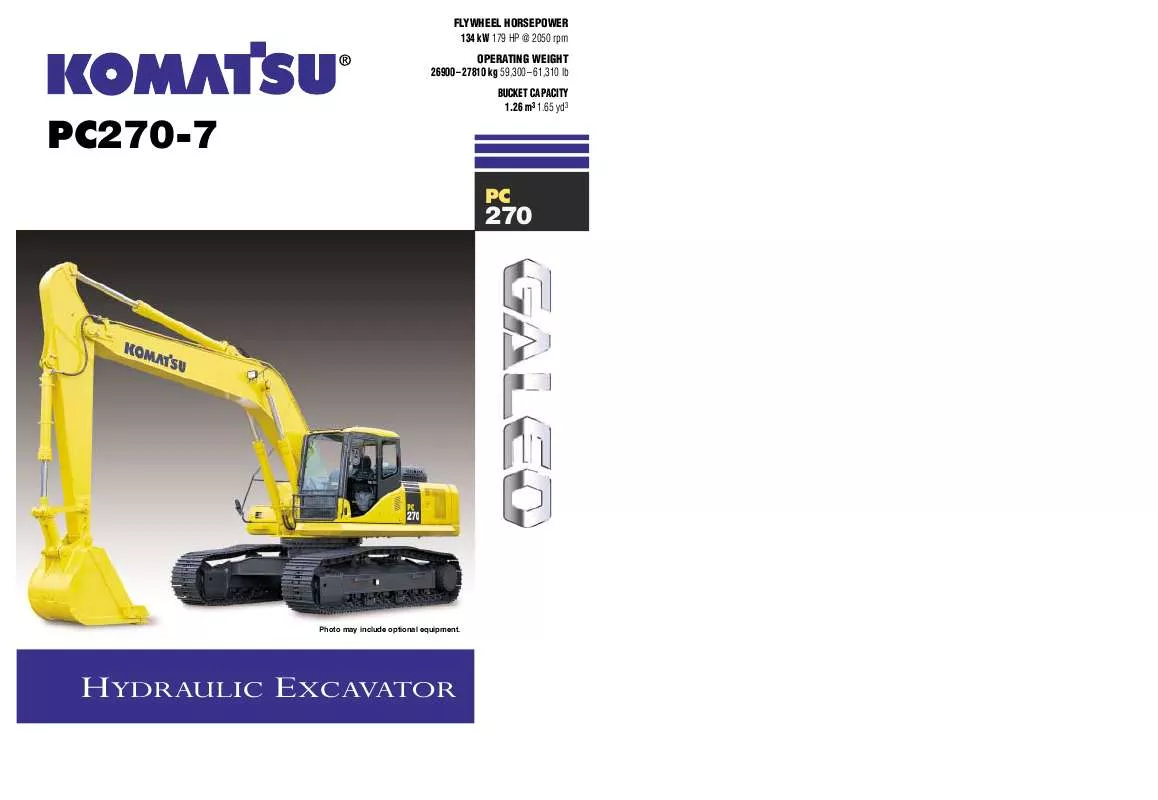

The PC270-7 gets its exceptional power and work capacity from a Komatsu SAA6D102E-2 engine. Output is 134 kW 179 HP, providing increased hydraulic power and improved fuel efficiency.

Hydraulics

Unique two-pump system ensures smooth compound movement of the work equipment. [. . . ] The large cab enables full flat reclining of the seat back with headrest.

The right side window pillar has been removed and the rear pillar reshaped to provide better visibility. Pump/engine room partition prevents oil from spraying on the engine if a hydraulic hose should burst. Thermal and fan guards are placed around high-temperature parts of the engine and fan drive. Steps with non-skid sheet

Photo may include optional equipment.

Pressurized Cab

With optional air conditioner, air filter and a higher internal air pressure (6. 0 mm Aq 0. 2" Aq) prevent external dust from entering the cab.

Low Noise Design

Noise level is remarkably reduced, not only engine noise but also noise when swinging and hydraulic relief.

and large handrail. Steps with non-skid sheet provide anti-slip footing for maintenance.

Seat with headrest reclined full flat Photo may include optional equipment.

Low Vibration with Cab Damper Mounting

PC270-7 uses new, improved multi-layer viscous mount system that incorporates longer stroke and the addition of a spring. The new cab damper mounting combined with strengthened left and right side decks aids vibration reduction at operator seat. Vibration at floor is reduced from 120 dB (VL) to 115 dB (VL).

dB (VL) is index for expressing size of vibration.

Automatic Air Conditioner (optional)

A 6, 900 kcal air conditioner is utilized. The bi-level control function keeps the operator's head and feet cool and warm respectively. This improved air flow function keeps the inside of the cab comfortable throughout the year.

Multi-Position Controls

The multi-position, pressure proportional control levers allow the operator to work in comfort while maintaining precise control. A double-slide mechanism allows the seat and controllers to move together or independently, allowing the operator to position the controllers for maximum productivity and comfort.

Large Handrail

Rubber Spring

Silicon Oil

Seat Sliding Amount: 340 mm 13. 4", increased 120 mm 4. 7"

Comparison of Riding Comfort Cab Damper Mounting Multi-Layer Viscous Mount

Pitch vertical direction on graph shows size of vibration. Conditions: Traveling over obstacle one side track Traveling speed forward high

Skylight

Sliding Window

Thermal Guard and Non-skid Sheet

Washable Cab Floormat The PC270-7's cab floormat is easy to keep clean. The gently inclined surface has a flanged floormat and drainage holes to facilitate runoff.

Floor Vibration

Defroster

Cab Frame Mounted Wiper

Bottle Holder and Magazine Rack

6

7

PC270-7 H Y D R A U L I C E X C A V A T O R

HYDRAULIC EXCAVATOR

PC270-7 0

MAINTENANCE FEATURES

Easy Maintenance

Komatsu designed the PC270-7 to have easy service access. We know by doing this, routine maintenance and servicing are less likely to be skipped, which can mean a reduction in costly downtime later on. Here are some of the many service features found on the PC270-7. Easy Radiator Cleaning Clearance between radiator and oil cooler is increased to facilitate radiator core cleaning with an air nozzle.

Easy Radiator Cleaning

SPECIFICATIONS

ENGINE Model . Water-cooled, 4-cycle, direct injection Aspiration . 2 each side Number of track rollers (each side) . 7 COOLANT AND LUBRICANT CAPACITY

(REFILLING)

HYDRAULICS Type . HydrauMind (Hydraulic Mechanical Intelligence New Design) system, closed-center system with load sensing valves and pressure compensated valves Number of selectable working modes . Variable displacement piston type Pumps for . Boom, arm, bucket, swing, and travel circuits Maximum flow. Self-reducing valve Hydraulic motors: Travel . [. . . ] . 70%, 35° Maximum travel speed: High 5. 5 km/h 3. 4 mph *(4. 5 km/h 2. 8 mph) (Auto-Shift) Mid 4. 1 km/h 2. 5 mph *(3. 3 km/h 2. 1 mph) Low 3. 0 km/h 1. 9 mph *(2. 8 km/h 1. 8 mph) Service brake Hydraulic lock Parking brake . . Mechanical disc brake *with optional heavy duty travel motor

Removal and installation of air conditioner filter element, without tools, facilitates cleaning.

Fuel Tank Capacity Increased Fuel tank capacity is increased from 340 ltr 89. 8 U. S. gal to extend operating hours before refueling. The fuel tank is treated for rust prevention and improved corrosion resistance.

8

9

DIMENSIONS

Arm Length A B C D E F G H I J K L M N O P Q Overall length Length on ground (transport) Overall height (to top of boom) Overall width Overall height (to top of cab) Ground clearance, counterweight Ground clearance (minimum) Tail swing radius Track length on ground Track length Track gauge Width of crawler Shoe width Grouser height Machine cab height Machine cab width Distance, swing center to rear end 2500 mm 9940 mm 5960 mm 3320 mm 3190 mm 3100 mm 1186 mm 498 mm 2940 mm 3700 mm 4625 mm 2590 mm 3190 mm 600 mm 36 mm 2200 mm 2710 mm 2905 mm 8'2" 32'7" 19'7" 10'11" 10'6" 10'2" 3'11" 1'8" 9'8" 12'2" 15'2" 8'6" 10'6" 23. 6" 1. 4" 7'3" 8'11" 9'6" 3045 mm 9790 mm 5180 mm 3210 mm 10'0" 32'1" 17'0" 10'6" 3500 mm 9890 mm 4790 mm 3280 mm 11'6" 32'5" 15'9" 10'9"

LIFTING CAPACITY WITH LIFTING MODE ON MULTI-FUNCTION COLOR MONITOR A A: Reach from swing center B: Bucket hook height C: Lifting capacity Cf: Rating over front Cs: Rating over side : Rating at maximum reach Conditions: 5850 mm 19'2" one-piece boom 1. 26 m3 1. 65 yd3 SAE heaped bucket Shoe width: -- 600 mm 23. 6" triple grouser

B C

A P H, Q

B A Cf *3250 kg *7, 200 lb *3100 kg *6, 900 lb *3150 kg *7, 000 lb *3350 kg *7, 400 lb *3700 kg *8, 200 lb *4300 kg *9, 500 lb 5050 kg 11, 100 lb 6000 kg 13, 200 lb 8350 kg 18, 400 lb 7. 6 m 25'

Arm: 3045 mm 10'0" MAX Cs *3250 kg *7, 200 lb *3100 kg *6, 900 lb *3150 kg *7, 000 lb 3050 kg 6, 800 lb 2950 kg 6, 500 lb 3000 kg 6, 600 lb 3300 kg 7, 300 lb 3950 kg 8, 700 lb 5500 kg 12, 100 lb Arm: 2500 mm 8'2" A B 7. 6 m 25' 6. 1 m 20' 4. 6 m 15' 3. 0 m 10' 1. 5 m 5' Om 0' 1. 5 m 5' 3. 0 m 10' 4. 6 m 15' Cf *5250 kg *11, 500 lb *5050 kg *11, 100 lb *5100 kg *11, 300 lb 5200 kg 11, 500 lb 5050 kg 11, 100 lb 5200 kg 11, 500 lb 5750 kg 12, 700 lb 7100 kg 15, 600 lb *8950 kg *19, 800 lb MAX Cs *5250 kg *11, 500 lb 4650 kg 10, 300 lb 3850 kg 8, 500 lb 3450 kg 7, 600 lb 3350 kg 7, 300 lb 3400 kg 7, 500 lb 3800 kg 8, 300 lb 4650 kg 10, 300 lb 7150 kg 15, 700 lb Cf Cf

Bucket: 1. 26 m3 1. 65 yd3 SAE heaped 7. 6 m 25' Cs Cf 6. 1 m 20' Cs Cf

Shoe: 600 mm 23. 6" triple grouser 4. 6 m 15' Cs Cf 3. 0 m 10' Cs Cf 1. 5 m 5' Cs

E

C O F

6. 1 m 20' 4. 6 m 15' 3. 0 m 10' 1. 5 m 5' Om 0' 1. 5 m 5'

*4250 kg *9, 400 lb *6200 kg *13, 700 lb 6100 kg 13, 500 lb 5950 kg 13, 100 lb 5800 kg 12, 700 lb 5700 kg 12, 600 lb

*4250 kg *9, 400 lb 4250 kg 9, 400 lb 4100 kg 9, 100 lb 3950 kg 8, 700 lb 3800 kg 8, 400 lb 3750 kg 8, 200 lb

*6250 kg *13, 700 lb *7100 kg *15, 700 lb *8400 kg *18, 500 lb 8600 kg 18, 900 lb 8300 kg 18, 300 lb 8150 kg 17, 900 lb 8150 kg 17, 900 lb

*6250 kg *13, 700 lb 6400 kg 14, 100 lb 6050 kg 13, 400 lb 5700 kg 12, 600 lb 5450 kg 12, 000 lb 5300 kg 11, 700 lb 5300 kg 11, 700 lb *10750 kg *23, 700 lb *13300 kg *29, 300 lb 13400 kg 29, 500 lb 13200 kg 29, 100 lb 13200 kg 29, 100 lb *11950 kg *26, 400 lb 9750 kg 21, 500 lb 8950 kg 19, 800 lb 8500 kg 18, 700 lb 8300 kg 18, 300 lb 8350 kg 18, 400 lb 8600 kg 18, 900 lb *16950 kg *37, 300 lb *8600 kg *19, 000 lb *9800 kg *21, 600 lb *13950 kg *30, 800 lb *20100 kg *44, 300 lb *16950 kg *37, 400 lb *16950 kg *37, 300 lb *8600 kg *19, 000 lb *9800 kg *21, 600 lb *13950 kg *30, 800 lb 17150 kg 37, 800 lb *16950 kg *37, 400 lb *8650 kg *19, 100 lb *13400 kg *29, 600 lb *8650 kg *19, 100 lb *13400 kg *29, 600 lb

G K D, L

M

I J B

N

WORKING RANGE

H

11(m) 10 9 8 7 6

3. 0 m 10' Arm A B C D E F G

G. L.

2500 mm 9620 mm 6720 mm 5940 mm 4800 mm

8'2" 31'7" 22'1" 19'6" 15'9"

3045 mm 7035 mm 6460 mm 5650 mm 6320 mm 10100 mm 9990 mm 3430 mm

10'0" 23'1" 21'2" 18'6" 20'9" 33'2" 32'9" 11'3"

3500 mm 10130 mm 7200 mm 6940 mm 5930 mm 6790 mm 10570 mm 10390 mm 3490 mm

11'6" 33'3" 23'7" 22'9" 19'5" 22'3" 34'8" 34'1" 11'5"

4. 6 m 15'

Max. [. . . ]