Detailed instructions for use are in the User's Guide.

[. . . ] Rigid frame for superior digging performance. Single plate frame design employing multiple castings is proven in both lab and field tests. Operator's safety is built into the cab with the use of a ROPS/FOPS canopy, a two-door system, and an emergency ladder.

The Most Advanced Technology

The dream has come true. Advanced Joystick Steering System (AJSS) with light, short strokes for perfect steering accuracy.

Hi-Cab is extra long and wide to provide a comfortable work environment. [. . . ] From his vantage point, 6170 mm 20'3" from the ground, the seated operator has a safe, unobstructed full view of the bucket and the inside of a 240-ton truck body.

6

7

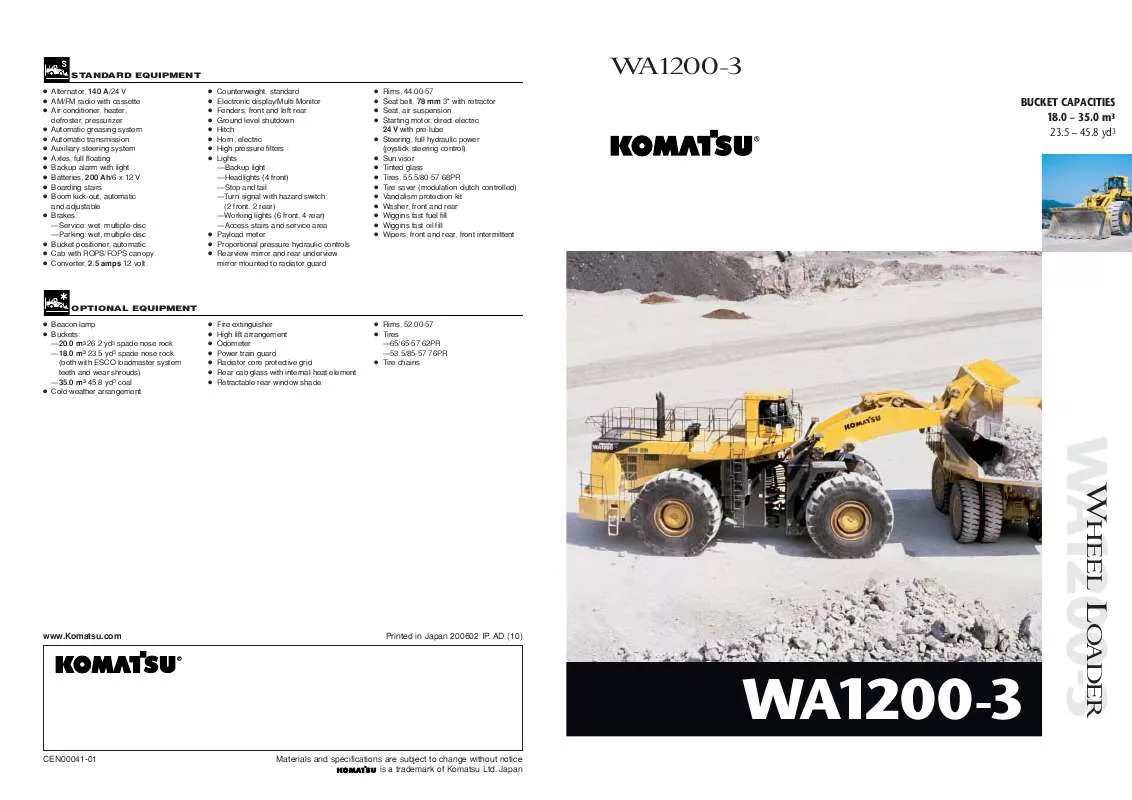

WA1 200-3

WHEEL LOADER

KOMATSU DESIGNED KOMATSU DESIGNED

RELIABILITY RELIABILITY

Integrating the latest technology in all areas of design, Komatsu has developed the WA1200-3 Mountain Mover as the most reliable, durable wheel loader for working in the harshest mining conditions.

Exclusive Komatsu Design Features Power Train, Axles, Transmission, and Hydraulic Components

The power train transforms 1165 kW 1560 HP into 1127 kN 115000 kg 253, 500 lb traction and 1274 kN 130000 kg 286, 600 lb breakout force. All components within the power train, from bolts to final gearing, are all Komatsu-designed. Designed to bear large loads and transmit large amounts of tractive power, Komatsu's full floating axle is used along with its planetary style transmission--another exclusive Komatsu feature with proven industry experience. The variable displacement hydraulic pump and hydraulic cylinders are also Komatsu-built components.

Safe Durable Service Brakes

The WA1200-3 uses Komatsudesigned sealed wet disc brakes. This proven design, coupled with a brake oil cooling system, provides reliable and durable final drive braking while downhill traveling with full loads and in all load and carry operations.

Centralized Filter Layout

Torque converter, transmission, engine oil, and fuel filters have been centrally located for ease of replacement from the ground.

Quick Fluid Change-out System

Hydraulic oil, transmission/torque converter oil, engine oil, and engine coolant can all be changed from the ground with a quickfill/change-out system. A fast-fill fuel system is also included as standard equipment. Wiggins Quickfill systems are used.

Automatic Greasing System

A microprocessor-based system ensures a preset supply of lubrication is delivered to all lube points at the proper intervals to help reduce maintenance costs.

Rigid Frame

Frame is designed to accommodate actual working loads, and simulated computer testing proves its strength prior to building. To increase frame reliability, steel castings have been incorporated at all frame pivot points to eliminate excessive welding lines.

Steps, Ladders, Doors, Hinged Radiator Grille, Handrails

Ladders and steps are arranged to provide safe access to each maintenance point. All doors are easy to open and provide accessibility for maintenance and cleaning. The radiator grille is a hinged design and opens as a door for easy access and cleaning. Safety handrails and steps are used at each maintenance point above ground level.

8

9

WA1 200-3

WHEEL LOADER

OPERATOR'S OPERATOR'S COMPARTMENT COMPARTMENT

Designed with the operator in mind, the operator's compartment promotes comfort and efficient operation for both experienced and inexperienced operators alike.

Floor Rear Frame Rubber

Comfortable Operator's Seat

An air suspension operator's seat is supplied as standard equipment. It displays on-line travel speed, gear position, and other important travel-related information. It also has diagnostic functions.

Automatic Transmission Allows Load and Carry Operations Without Shifting Gears

This system automatically selects the optimum gear in accordance with the conditions, travel speed, engine speed, etc. The transmission is controlled by the Komatsu Electronic Control Modulation Valve (ECMV) system. The operation is made much easier as the operator no longer has to shift from gear to gear while carrying loads during the work cycle. 10

Multi Monitor

On the right of the panel is the color graphic system. Through this system remote boom positioning is set. Gauges displayed on the monitor include: engine water temperature, oil pressure, fuel level, and payload meter. Maintenance diagnostic information is also available on the monitor. 11

WA1 200-3

WHEEL LOADER

COST-REDUCING COST-REDUCING FEATURES FEATURES

Inherent to the Komatsu design are features which help mine operators reduce machine operational costs.

Ultra Wide Base Tire Option

65/65-57 62PR ultra wide base tires have been developed exclusively for the WA1200-3. With the reduction of ground pressure, increase of rubber material, and larger air volume, incidents of premature tire wear and tire cutting have been reduced. The result of this tire technology along with the Tire Saver feature is longer tire life and reduced vehicle-operating costs.

SAFETY SAFETY FEATURES FEATURES

Komatsu put a high priority on the safety of the machine operator while designing the WA1200-3 Mountain Mover.

Large Cab Design With Safety Protection

The oversized cab is designed with the operator's safety in mind. [. . . ] gal

BRAKES TIRES Service brakes: Hydraulically-actuated, wet, multi-disc brakes actuated on four wheels. Parking brake: Wet, multi-disc, hydraulically-released, spring applied in the transmission. Select proper tires based on job requirements. 55. 5/80-57 68PR

55. 5/80-57 tire 65/65-57 tire Full turn (40°) 55. 5/80-57 tire 65/65-57 tire Dump clearance, maximum height and 45° dump angle 55. 5/80-57 tire (tooth end measure) 65/65-57 tire Reach at maximum height and 45° dump angle 55. 5/80-57 tire (tooth end measure) 65/65-57 tire Height to hinge pin Fully raised 55. 5/80-57 tire 65/65-57 tire Operating height Fully raised 55. 5/80-57 tire 65/65-57 tire Overall length Bucket ground Turning radius* Digging depth 0° 55. 5/80-57 tire 65/65-57 tire 10° 55. 5/80-57 tire 65/65-57 tire Breakout force (bucket cylinder) Operating weight 55. 5/80-57 tire 65/65-57 tire

Bucket width Bucket width with tire protector Bucket weight Static tipping loads Straight

Standard Boom, 20. 0 m3 26. 2 yd3 Spade Nose Rock With Teeth 20. 0 m3 26. 2 yd3 3 17. 2 m 22. 5 yd3 6400 mm 21'0" 6550 mm 21'6" 23840 kg 52, 560 lb 119800 kg 264, 100 lb 123800 kg 272, 900 lb 104800 kg 231, 000 lb 107700 kg 237, 400 lb 6285 mm 6350 mm 2970 mm 2905 mm 8830 mm 8895 mm 11865 mm 11930 mm 18200 mm 14330 mm 290 mm 175 mm 785 mm 720 mm 1274 kN 130000 kg 205200 kg 210200 kg 20'7" 20'10" 9'9" 9'6" 29'0" 29'2" 38'11" 39'2" 59'9" 47'0" 11. 4" 6. 9" 30. 9" 28. 3" 286, 600 lb 452, 390 lb 463, 400 lb

High Lift Boom, 18. 0 m3 23. 5 yd3 Spade Nose Rock With Teeth 18. 0 m3 23. 5 yd3 3 15. 0 m 19. 6 yd3 6400 mm 21'0" 6550 mm 21'6" 23170 kg 51, 080 lb 106800 kg 235, 454 lb 110300 kg 243, 200 lb 93500 kg 206, 100 lb 96000 kg 211, 600 lb 7005 mm 7070 mm 3045 mm 2980 mm 9480 mm 9545 mm 12410 mm 12475 mm 18840 mm 14700 mm 260 mm 195 mm 780 mm 715 mm 1236 kN 126000 kg 208300 kg 213300 kg 23'0" 23'2" 10'0" 9'9" 31'1" 31'4" 40'9" 40'11" 61'10" 48'3" 10. 2" 7. 7" 30. 7" 28. 1" 277, 782 lb 459, 200 lb 470, 200 lb

Static tipping load and operating weight shown include lubricants, coolant, full fuel tank, ROPS cab, front and rear fenders, and operator. [. . . ]